Method and device for galvanising substrates and solar cells

A technology of solar cells and electrolytic plating, applied in the direction of circuits, electrolytic components, electrical components, etc., can solve the problems of infeasibility in mass production and utilization, and achieve the effects of improving plating quality, increasing deposition speed, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

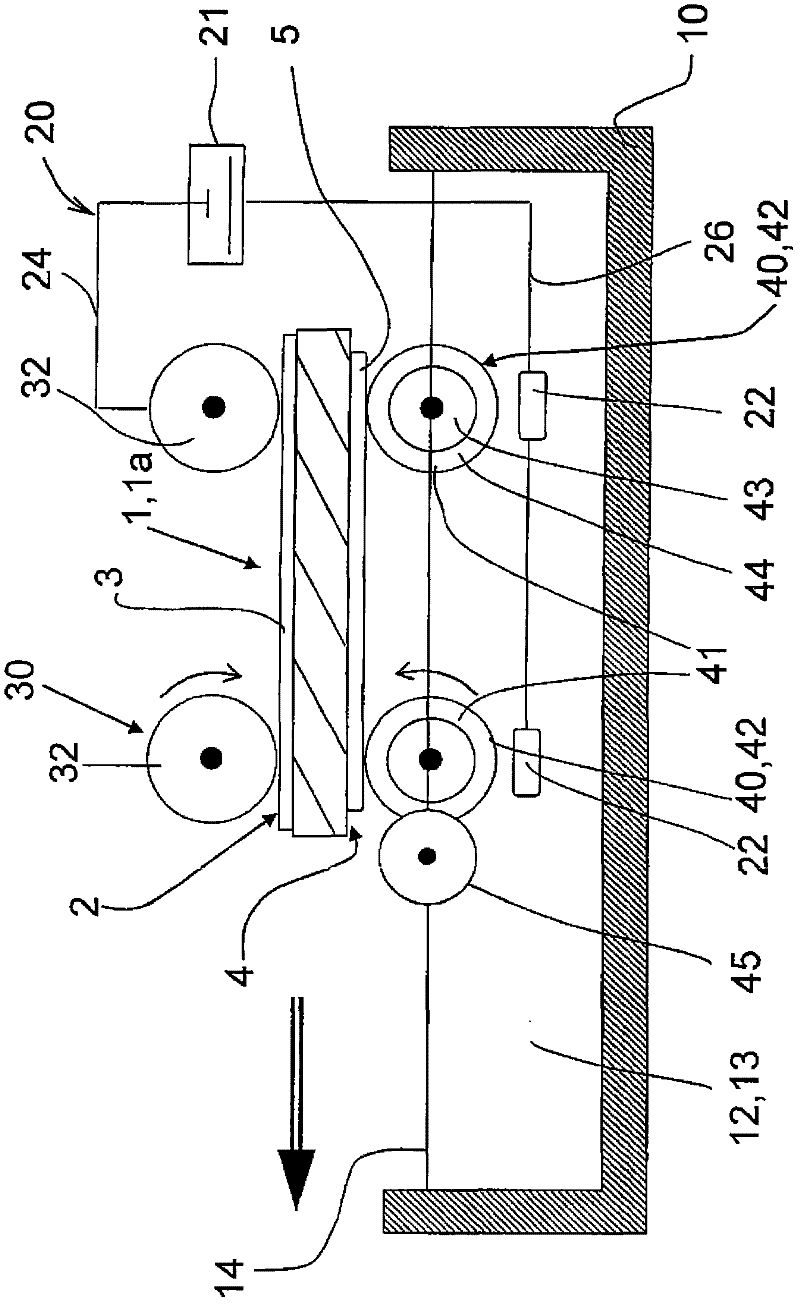

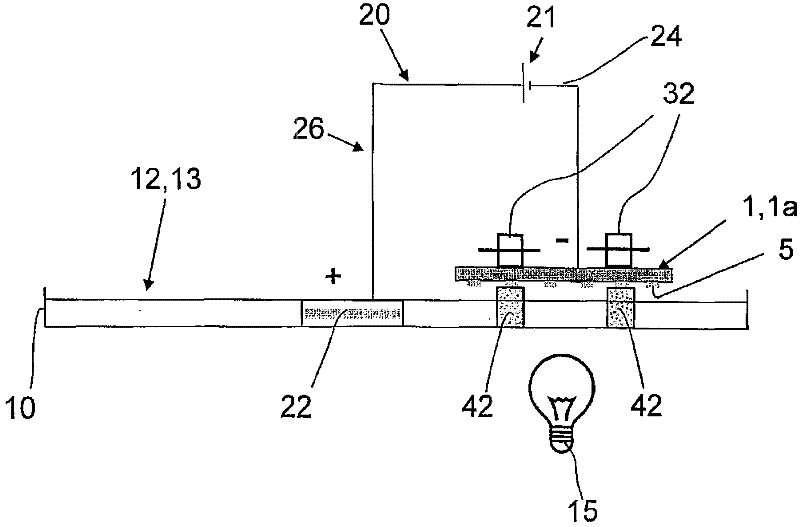

[0062] exist figure 1 A device for electroplating a substrate 1 is shown in , comprising a liquid reservoir 12 in the form of a plating tank 10 in which an electrolytic plating liquid 13 is located. In this embodiment, the substrate 1 is a solar cell 1a.

[0063] The substrate 1 is arranged between the upper transfer device 30 and the lower transfer device 40, and moves in the direction of the arrow. The two transfer devices 30 , 40 are arranged in such a way that the substrate 1 is located above the coating bath 10 which is open towards the top. The upper conveyor 30 has upper conveyor rollers 32, only two of which are drawn. The substrate 1 has a metallization 3 on the back side 2 which is contacted by a roller 32 on the upper right, which is connected via an electrical connection 24 to the negative pole of the power supply 21 . The positive pole of the power supply 21 is connected via an electrical connection line 26 to an electrode 22 which forms the anode and which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com