Technology for producing sponge from plant oil polyether

A vegetable oil and process technology, applied in the field of sponge technology, can solve the problems of unfavorable environmental protection and sustainable development, difficult to decompose, and rising prices of petrochemical products, so as to be beneficial to environmental protection and sustainable development, reduce production steps, and ease prices rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

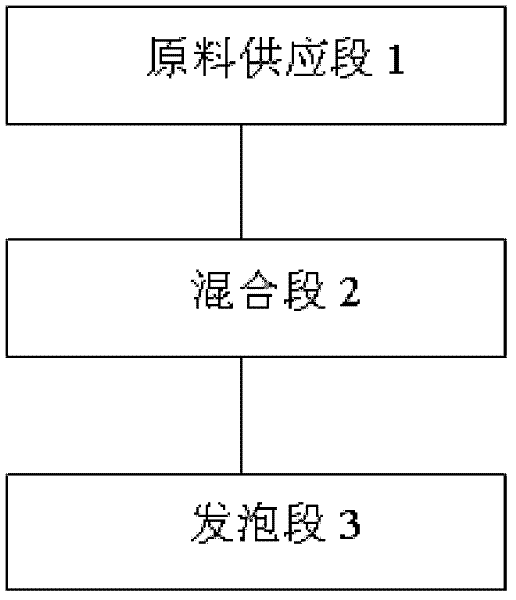

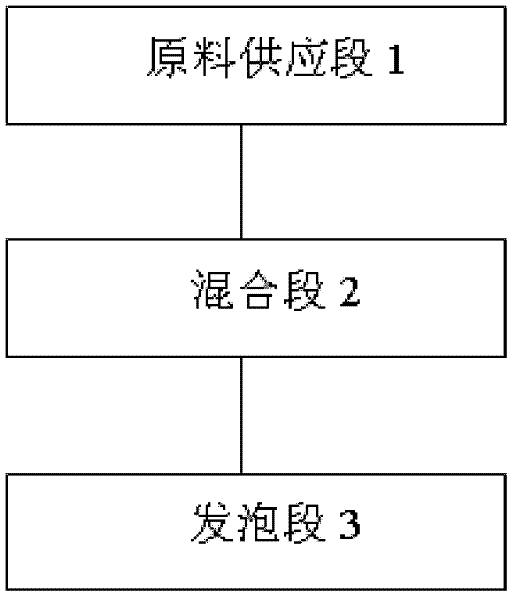

[0021] refer to figure 1 , Vegetable oil polyether production sponge process, including raw material supply section 1, mixing section 2, foaming section 3, first extract and synthesize polyether polyol from vegetable oil raw material, obtain vegetable oil polyether polyol. The raw material components of the raw material supply section 1 include a polyol component and an isocyanate component. The polyol component is a combined polyol component formed by mixing vegetable oil polyether polyol, chain extender, foaming agent, catalyst and foam stabilizer, and the isocyanate component includes isocyanate. The raw material components are respectively input into the working storage tank, and the temperature control system regulates the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com