Preparation method of polyvinyl chloride resin with high oil absorption rate

A technology of polyvinyl chloride resin and high oil absorption, which is applied in the field of preparation of polyvinyl chloride resin, can solve the problems of low oil absorption rate, and achieve the effects of high oil absorption rate, easy plasticization, and thin resin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

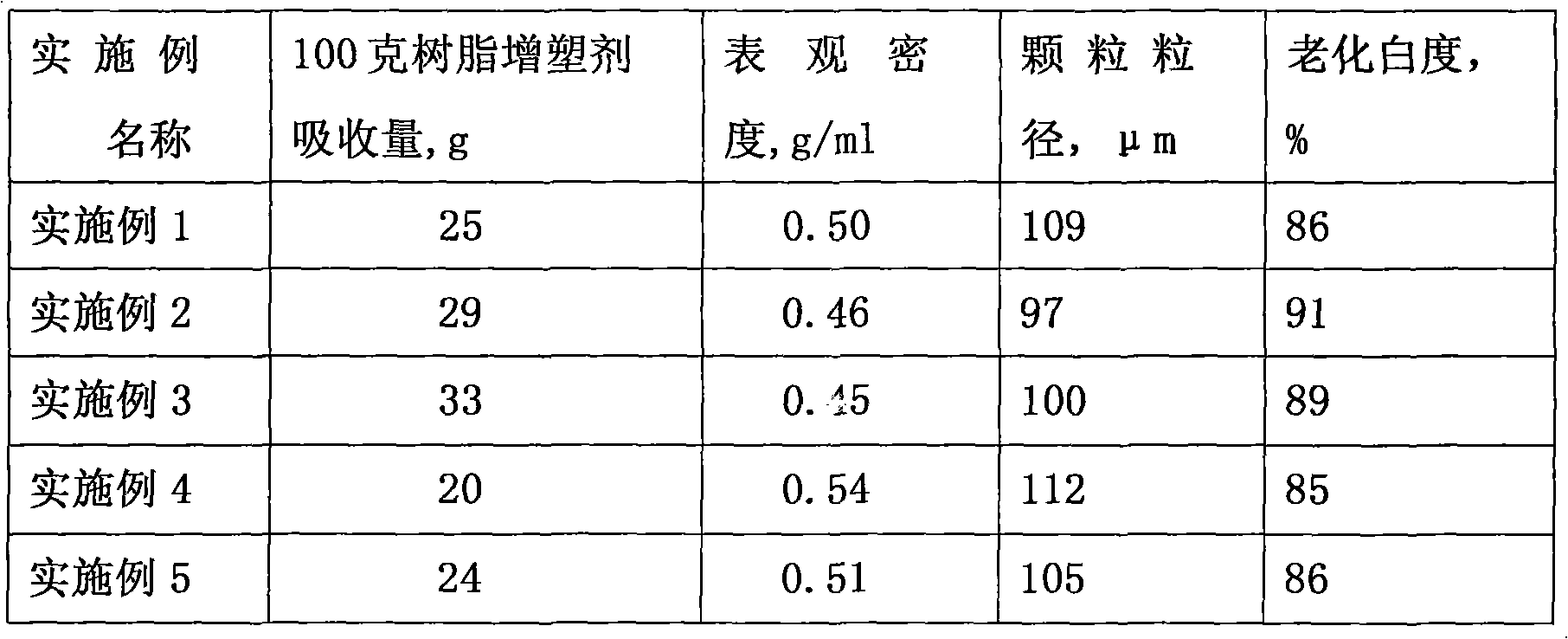

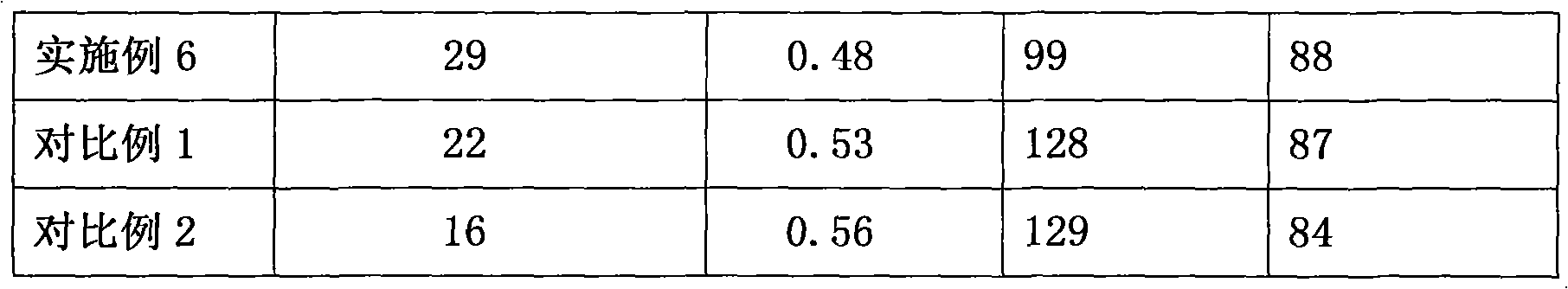

Examples

Embodiment 1

[0023] Component:

[0024] Vinyl chloride 3.0kg

[0025] Deionized water 4.0kg

[0026] Dispersion system high alcoholysis degree polyvinyl alcohol (polymerization degree 1000, alcoholysis degree 80%, mass concentration 5.1%) / low alcoholysis degree polyvinyl alcohol ((polymerization degree 300, alcoholysis degree 45%, mass concentration 34% ) / hydroxypropyl methylcellulose (the degree of methyl substitution is 1.9, the content is 30%, the degree of hydroxypropyl substitution is 0.25, the content is 10% and the mass concentration is 2.9%), the ratio is 3:1:2, 0.05kg

[0027] Initiation system Di-(2-ethylhexyl) peroxydicarbonate / cumyl peroxyneodecanoate, the ratio is 3:1, 20% aqueous emulsion, 0.015kg

[0028] Functional Auxiliary C 5 Normal alkanes, the addition amount is 0.15kg

[0029] Terminator Diethylhydroxylamine, 0.075g

[0030] Operation method:

[0031] Rinse the 10L polymerization kettle, apply the anti-sticking agent and rinse, then vacuumize, suck in the deioni...

Embodiment 2

[0033]Repeat Example 1, the difference is the functional auxiliary C in the component 5 Normal alkanes, the addition amount is 0.30kg. The performance test results of the resin particles are shown in Table 1.

Embodiment 3

[0035] Repeat Example 1, the difference is that the functional auxiliary agent is C in the component 5 、C 6 、C 7 Compound alkanes, the ratio is 1:1:1, and the addition amount is 0.3kg. The performance test results of the resin particles are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com