Ground potential rod cutter exchanging device

A ground potential and pole technology, applied in hoisting devices, portable lifting devices, overhead line/cable equipment, etc., can solve the economic loss of users and power companies, the inability of insulated bucket trucks to stop, and affect the power consumption of power users, etc. problems, to achieve the effect of improving the competitive advantage, expanding the adaptability and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

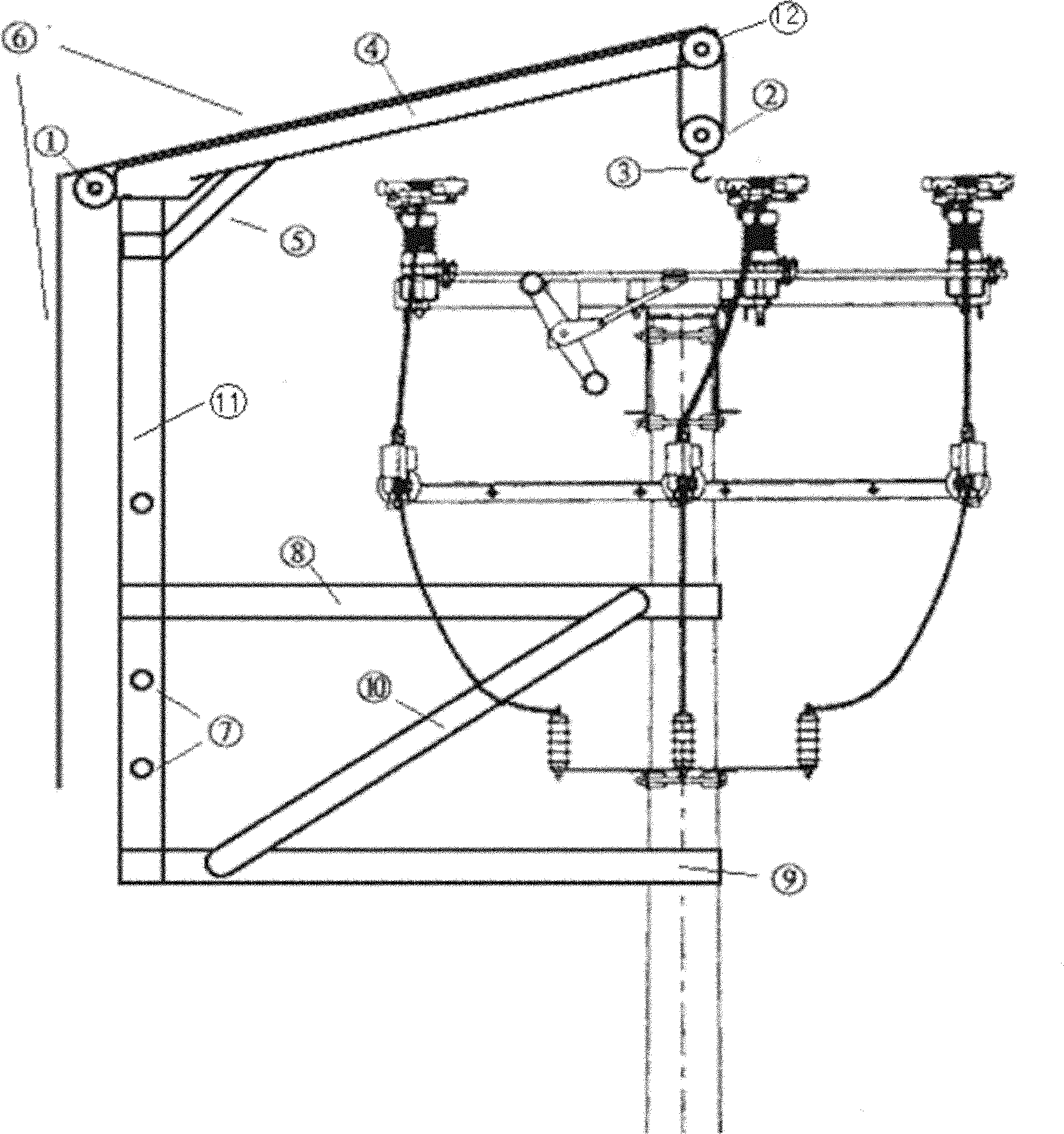

[0014] Such as figure 1 As shown, a ground potential pole-knife exchange device is arranged on a high-voltage line tower or an electric pole. The device includes a rotating bracket, a boom 4, a first fixed pulley 1, a hook 3, a rope 6, a second fixed pulley 12, Moving pulley 2. The rotating bracket is connected with a high-voltage line tower or a pole. The boom 4 includes a free end and a fixed end. The fixed end of the boom 4 is connected to the support, and the fixed end is provided with a first fixed pulley 1 . The fixed end of the boom 4 is provided with a second fixed pulley 12 . The rope 6 is sheathed in the first fixed pulley 1, the second fixed pulley 12, and the movable pulley 2 in sequence, and is fixed at the second fixed pulley 12. The movable pulley 2 is provided with a suspension hook 3 . The rotating bracket includes a horizontally fixed steering support rod 8, a horizontally fixed steering base support rod 9, and a longitudinal support rod 11. One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com