Method for evaluating cigarette flavor compensation technology

A flavor compensation and cigarette technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of tar reduction, lack of cigarette flavor, and bland cigarette flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

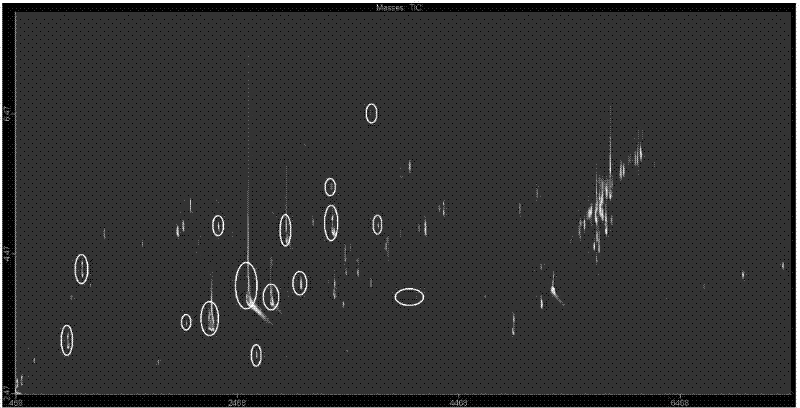

[0023] In order to investigate the role of comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry (GC×GC / TOFMS) in evaluating the effect of flavor compensation in cigarette product design, the trial production process of an experimental cigarette was tracked and evaluated.

[0024] Sensory evaluation of the blank leaf group of experimental cigarettes: the main flavor of tobacco is dominant, the richness of the aroma is lacking, the amount is slightly insufficient, there is a little miscellaneous smell, the mouthfeel and aftertaste are slightly poor, the feeling of dryness is slightly strong, and there is no obvious style characteristic.

[0025] The design requirements of the experimental cigarettes: the surface aroma used can endow the experimental cigarettes with a sweet and fruity aroma and a delicate aroma. The overall aroma is rich and thick, in harmony with the original aroma of tobacco, and has a unique style feature; the miscellaneous gas is re...

Embodiment 1

[0027] Example 1: Flavor Compensation Effect of Surface Fragrance I on Cigarettes

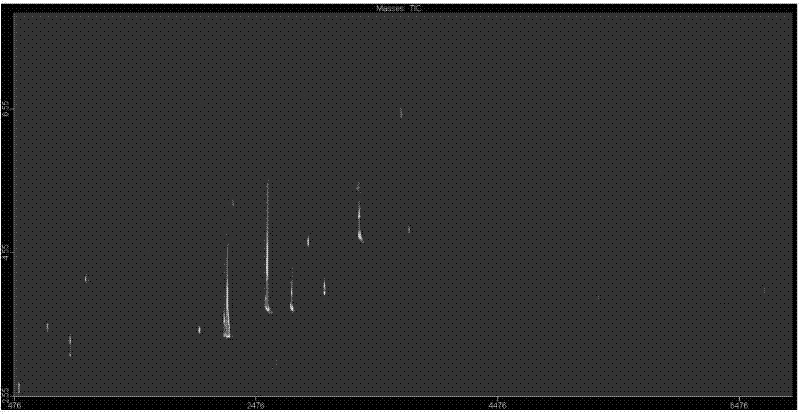

[0028] The GC×GC / TOFMS analysis method (including gas chromatography method, mass spectrometry method and data processing method) was optimized in the experiment, and qualitative and quantitative analysis was performed on epiglyph I. The two-dimensional profile (total ion current diagram) is shown in figure 1 . For chemical components with a similarity ≥ 800, combined with data such as total ion current, similarity and anti-similarity, a total of 74 chemical components that meet the matching requirements were identified, mainly including 15 alcohols, 15 esters, and 22 alkanes , 3 phenols, 2 ketones and 1 aldehyde.

[0029] The aroma of Biaoxiang I is mainly fruity, spicy, and sweet; it shows a fragrance style, which can enrich the fruity aroma, sweet aroma, increase the concentration of smoke, and increase the thickness of the base aroma.

[0030] The sensory evaluation of the experimental ci...

Embodiment 2

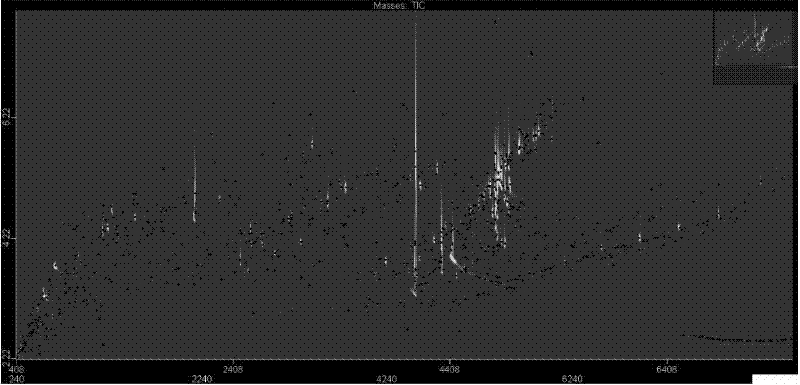

[0032] Example 2: Flavor Compensation Effect of Surface Fragrance II on Cigarettes

[0033] Aiming at the deficiencies shown in the sensory evaluation and chemical analysis data of Biaoxiang I, the experiment adjusted Biaoxiang I to get Biaoxiang II.

[0034] The scent of Biaoxiang II is fresh and fruity and sweet. Its main function is to enhance the fragrance style, enrich the fruity and sweet fragrance, make the smoke round and delicate, and increase the sweetness.

[0035] The sensory evaluation of the experimental cigarettes with added aroma Ⅱ is as follows: the cigarettes have better sweetness and fruity aroma and smell, the characteristics of the fragrance style are reflected, the aroma quality and aroma quantity are improved, the smoke is more delicate and soft, and the sense of roundness is enhanced , the head fragrance and body fragrance perform well, but there is a slight fault in the rear part of the fragrance, and the amount of fragrance is insufficient, which is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com