Bending test platform and method for prestressed concrete sheet pile

A concrete slab and bending test technology, which is applied in the direction of applying a stable bending force to test the strength of materials, can solve the problem that the bending test bench cannot realize the special-shaped and other problems, and achieves guaranteed reliability, simple structure, and expanded use. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

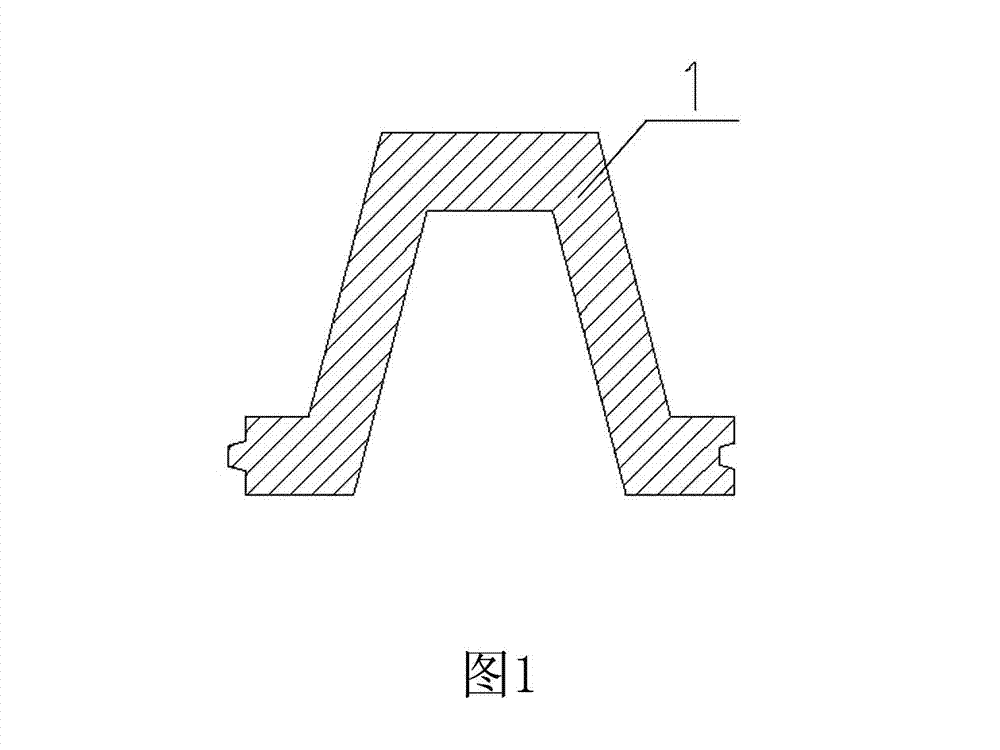

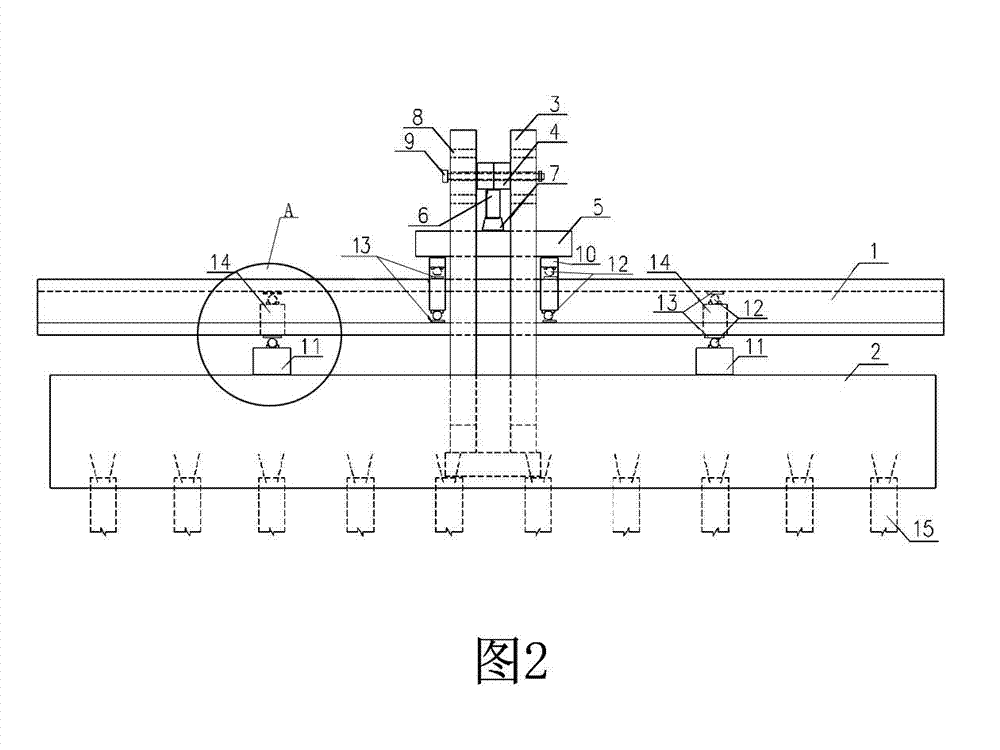

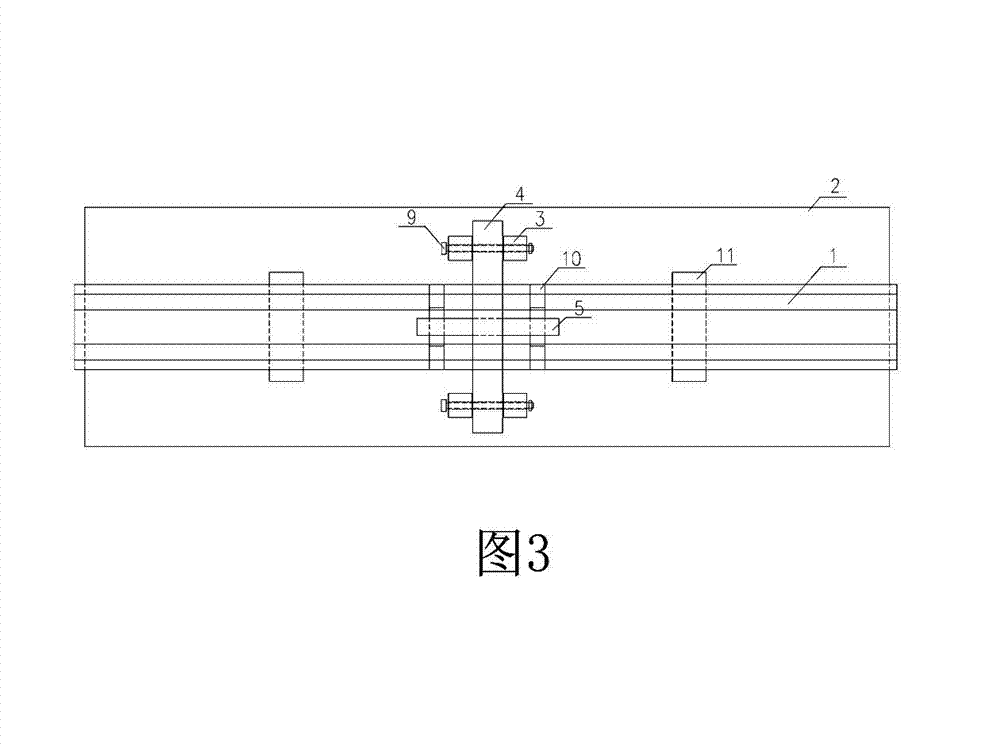

[0031] Examples see Figure 1 to Figure 5 As shown, a prestressed concrete sheet pile bending test bench includes a test piece, a concrete platform 2, a loading frame, a jack 6 and a load distribution beam 5, and the loading frame is composed of two columns 3 and a frame between the two columns The reaction beam 4 between them, the column 3 and the reaction beam 4 are connected by bolts 9, the bottom of the column 3 is pre-embedded in the concrete platform 2, and the test piece is supported on the concrete platform 2 through the support pad 11, The load distribution beam 5 and the reaction beam 4 are vertically arranged, and are supported on the test piece by the force transmission brackets 10 arranged at both ends thereof, and the jack 6 is arranged between the reaction beam 4 and the load distribution beam 5, so that The test piece is a U-shaped concrete sheet pile 1, and the force transmission bracket 10 matches the section of the U-shaped concrete sheet pile 1, and is clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com