Charge air cooling device for a combustion engine

A technology of charge air cooling and charge air, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of charge air coolers restricting charge air flexibility and huge integration costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

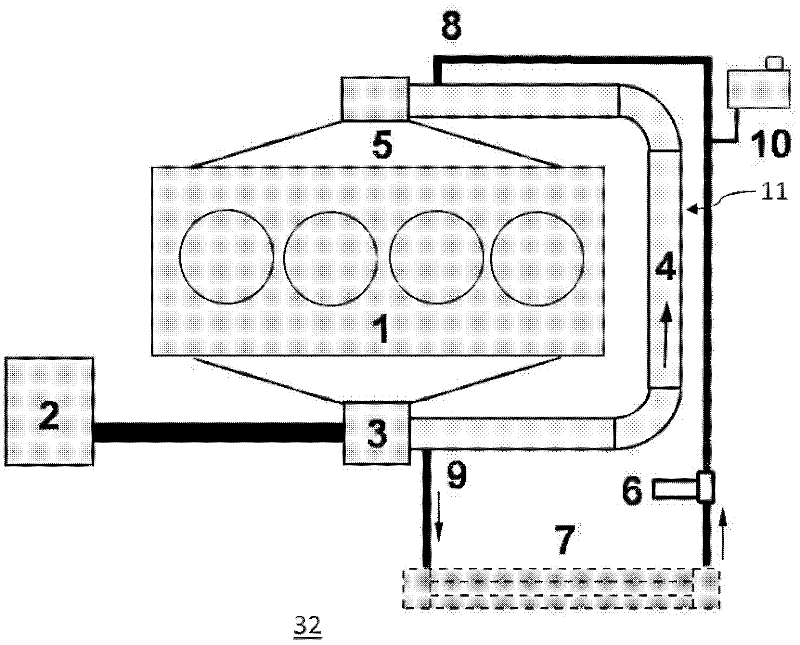

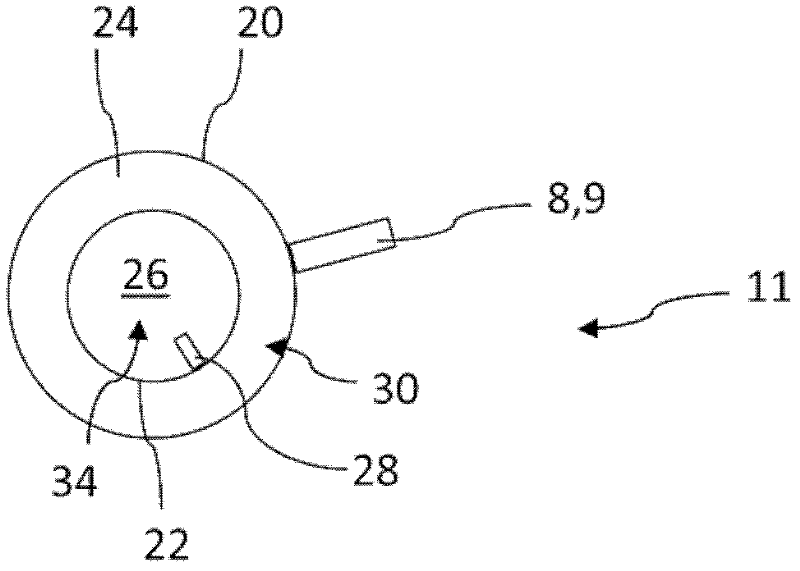

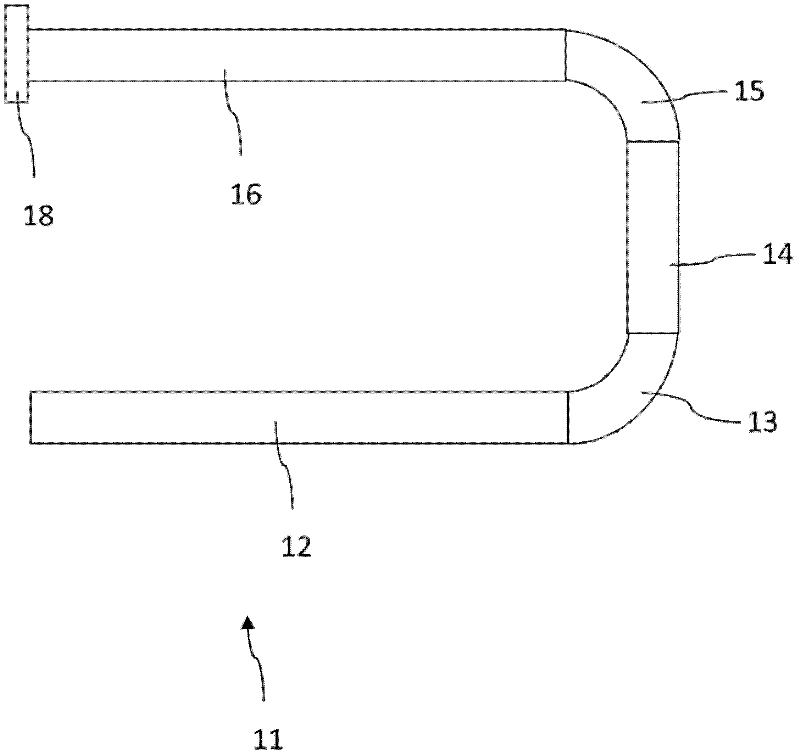

[0031] figure 1 The charge air cooling system shown in has a cooling circuit, in particular for cooling the charge air, which in this embodiment consists of a coaxial tube heat exchanger 11, a coolant outlet 9, a charge air cooler 7. A coolant pump 6, a coolant compensating container 10 and a coolant inlet 8 leading to a coaxial tube heat exchanger 11 are formed. A coaxial tube heat exchanger 11 extends between the compressor or supercharger 3 and the intake manifold 5 of the internal combustion engine 1 . The entire combustion air conduction path between the supercharger 3 and the intake manifold 5 here forms the cooling path 4 of the heat exchanger 11 .

[0032] In this connection, it is provided that the charge air guide provided downstream of the supercharger 3 and upstream of the internal combustion engine 1 is designed almost entirely as a cooling path of the coaxial tube heat exchanger 11 . As a result, the cooling efficiency of the intercooler can be increased, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com