Cluster rectification device

A technology of rectification and clustering, applied in fractionation and other directions, can solve the problem of high investment cost, and achieve the effect of good condensation effect, lower rising height and uniform airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

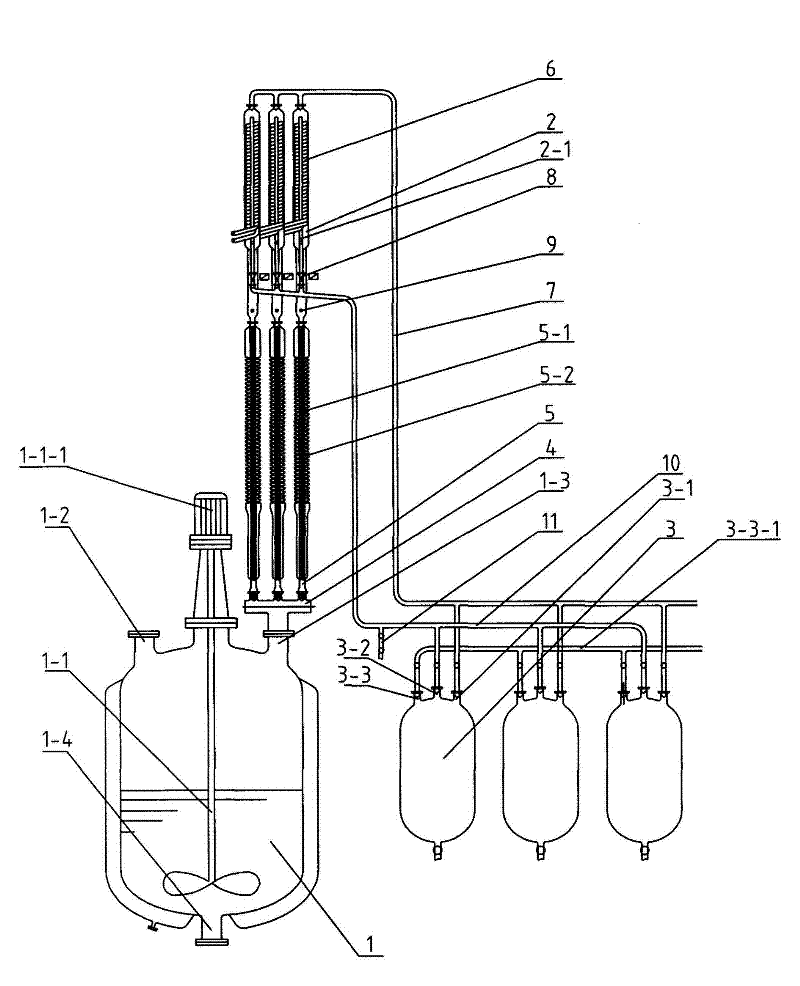

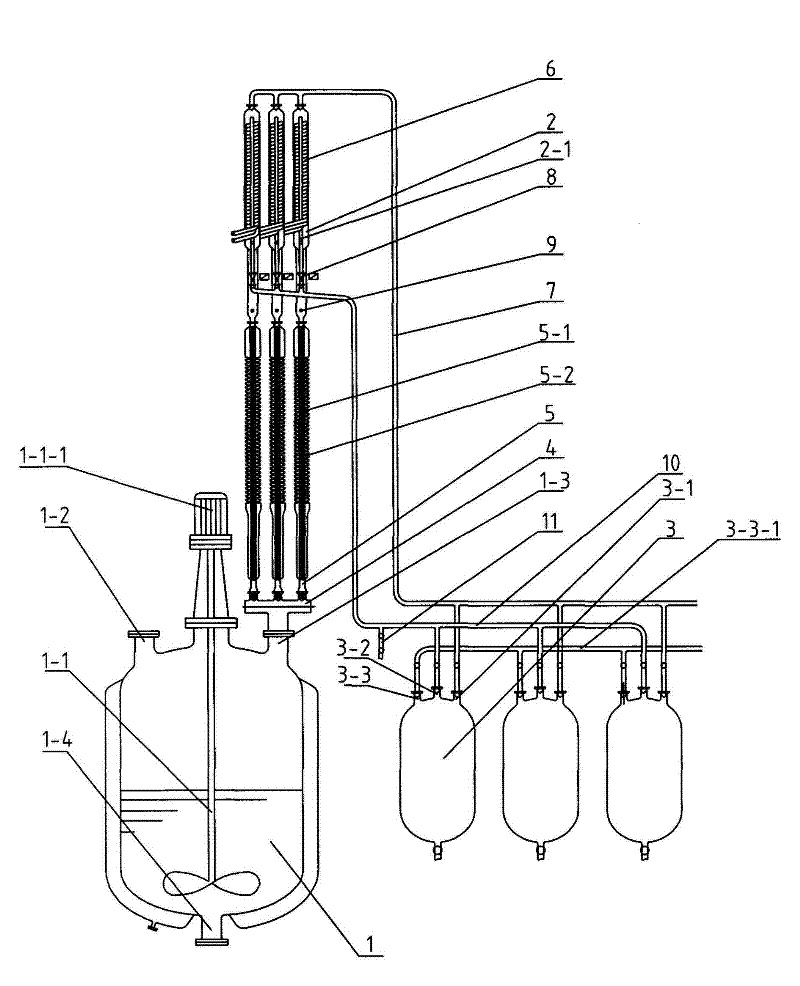

[0011] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

[0012] Such as figure 1 Shown, a kind of cluster rectification device, it comprises tower still 1, some rectifying heads 2 and some collecting metering tanks 3, and tower still 1 is provided with feed inlet 1-2, gas phase discharge outlet 1-3 and residual material Ports 1-4 also include a second pipeline 10, and the gas phase outlets 1-3 of the tower kettle 1 are connected in parallel with several small-diameter cluster rectification towers 5 through the cluster rectification disk distribution platform 4, and each cluster rectification The other end of the tower 5 communicates with the rectifying head 2 respectively. A condenser 6 is arranged on the rectifying head 2. The gas outlet of the rectifying head 2 is connected with a first pipeline 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com