optical module

一种光模块、光源的技术,应用在光模块领域,能够解决光模块损伤、不充分即时反馈、没有得到光模块和能量设施热接触等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

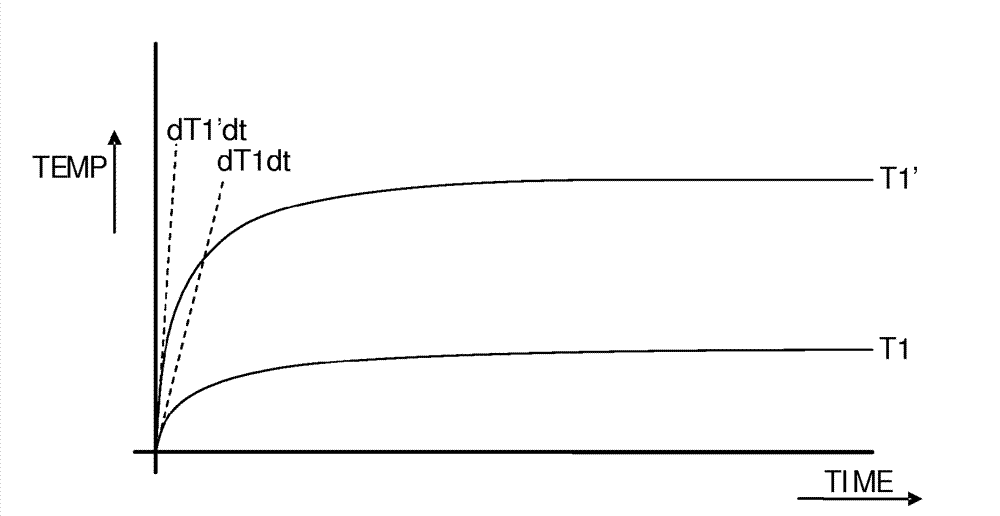

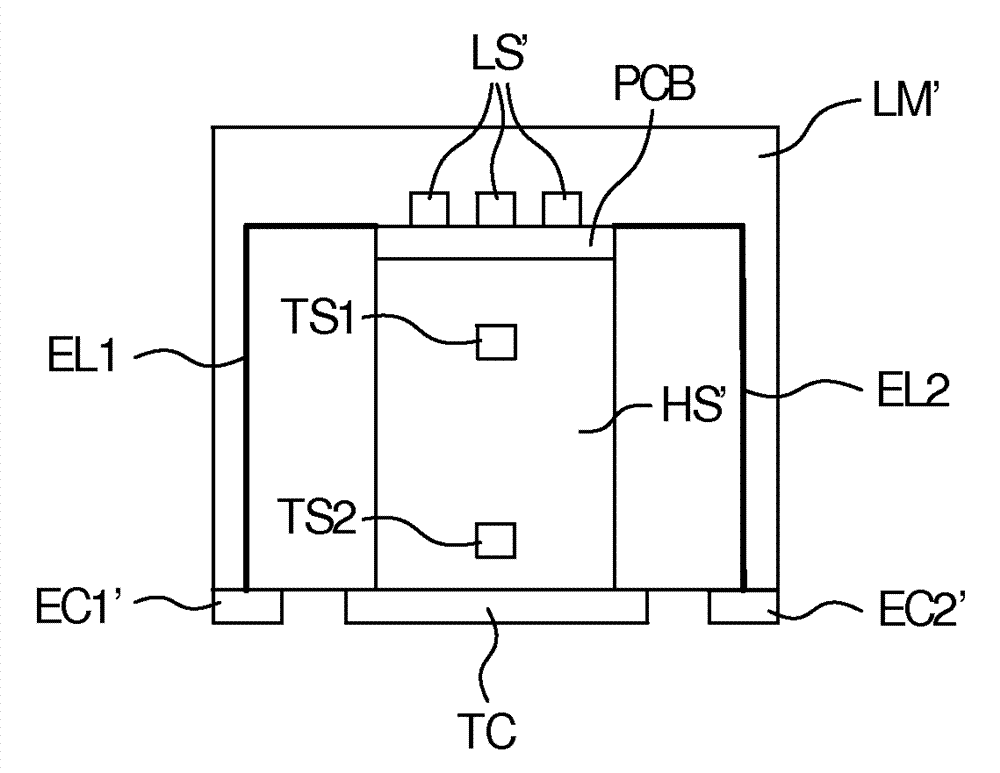

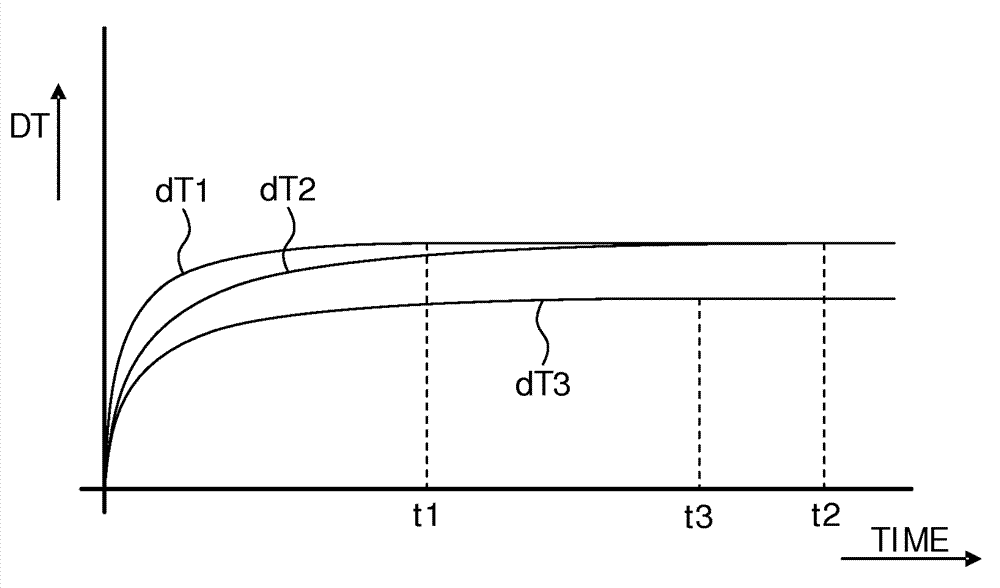

[0024] figure 1 A light module LM is described for electrical and thermal attachment to an energy installation EI having at least one power supply PS, wherein each power supply comprises two electrodes E1 , E2. The light module LM comprises: a light source LS emitting light L, which light source is a heat source when emitting light L; two electrical contacts EC1, EC2 contacting the electrodes E1, E2 of the at least one power supply PS and thereby establishing the light module LM and energy Electrical attachment between the installations EI; a control system CS arranged between the light source LS and the electrical contacts EC1, EC2 to control the power supplied to the light source LS; and a measurement system MS to measure the optical modules LM and The thermal resistance TR of the thermal attachment between the energy facilities EI. The control system CS is configured to reduce the power supplied to the light source LS to protect the light module LM from overheating when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com