Separable demoulding skeleton for manufacturing optic fiber loop of optic fiber gyroscope

An optical fiber loop and fiber optic gyroscope technology is applied in the field of detachable demolding skeleton, which can solve the problem that the skeleton and the optical fiber loop cannot be easily separated, and achieve the effects of high yield, high efficiency and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

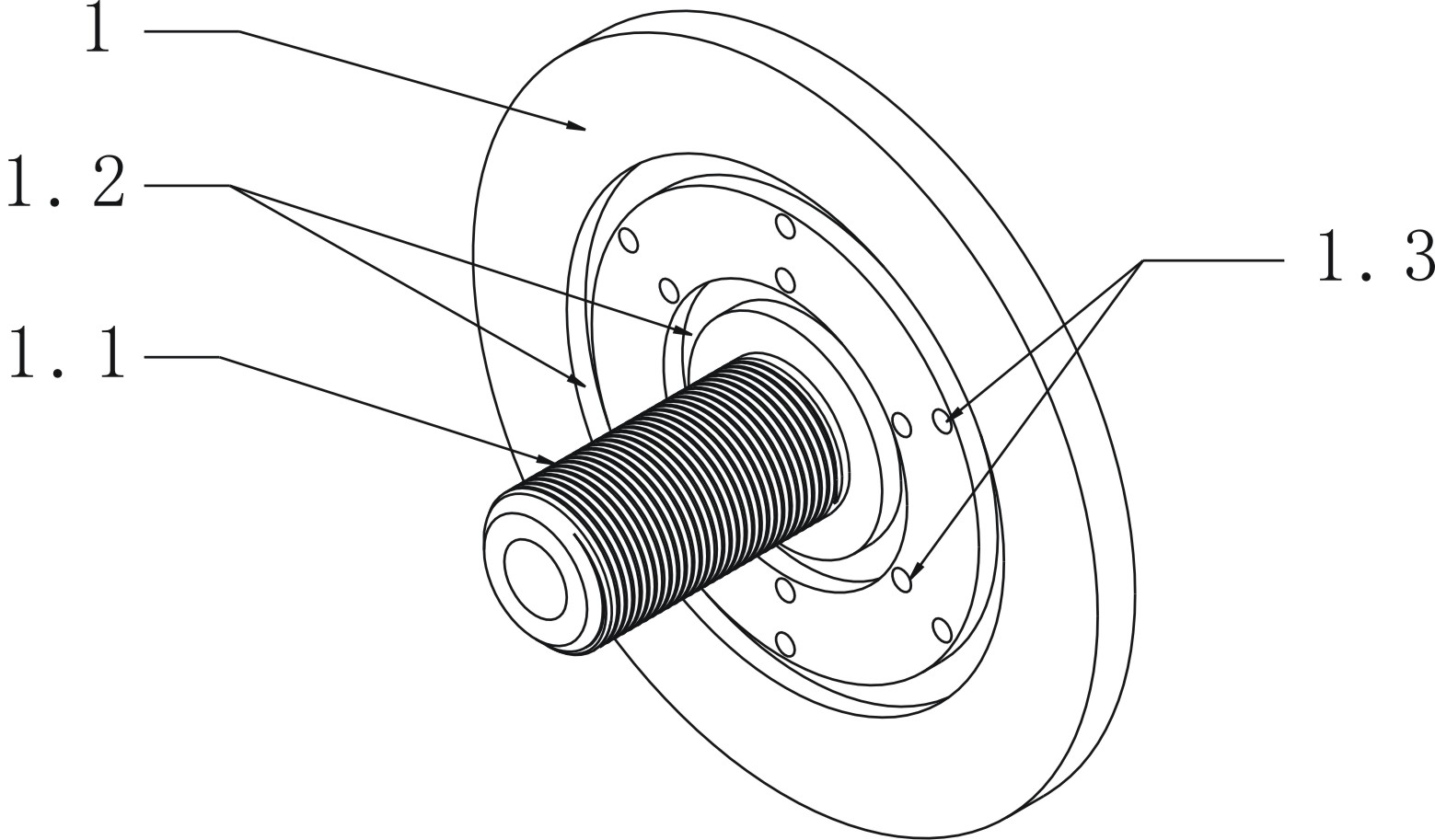

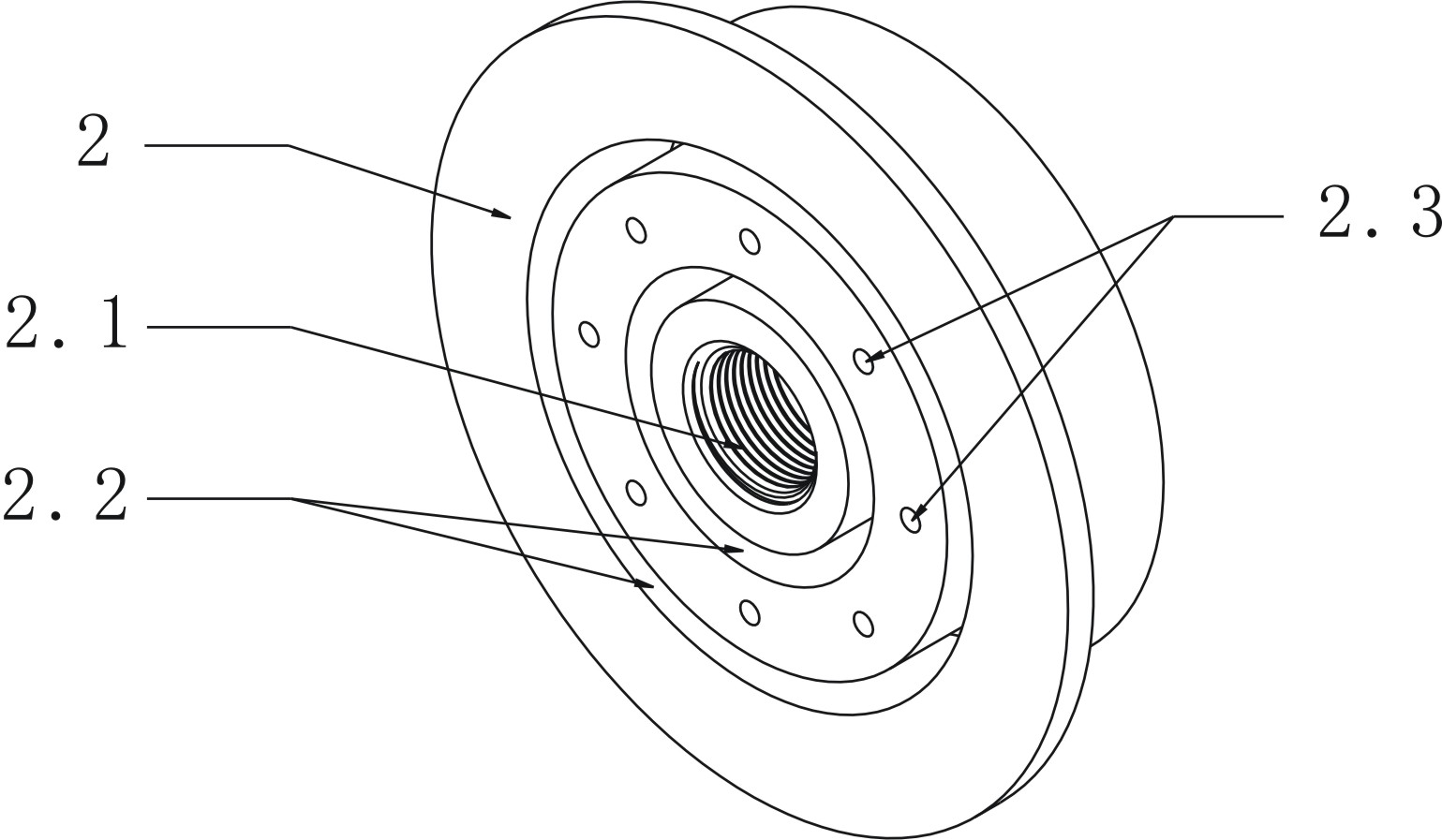

[0025] Such as Figure 1~4 and Image 6 As shown, a detachable demoulding framework for preparing fiber optic rings of fiber optic gyroscopes according to the present invention includes a first mounting plate 1, a second mounting plate 2 and a sector ring 3 composed of six sector pieces 3.1 . One side of the first installation disk 1 is provided with a hollow screw 1.1 perpendicular to the surface of the disk, six groups of twelve positioning screw holes 1.3 are evenly arranged around the hollow screw 1.1 on the first installation disk 1, and the first installation disk 1 surrounds the above-mentioned The hollow screw 1.1 is also provided with two first annular grooves 1.2. The second mounting plate 2 is provided with a screw hole 2.1 matched with the above-mentioned hollow screw rod 1.1, and two second annular grooves 2.2 are arranged around the screw hole 2.1 on it. In this embodiment, the second annular groove 2.2 is larger than the first annular groove. 1.2 deep, so tha...

Embodiment 2

[0029] Such as Figure 1~2 , Figure 5~6 As shown, another detachable demolding frame for preparing the fiber ring of the fiber optic gyroscope according to the present invention includes a first mounting plate 1 , a second mounting plate 2 and a fan ring 3 . Among them, the structure of the first installation disk 1 and the second installation disk 2 is the same as that of the first embodiment, the difference mainly lies in the fan ring 3, the fan ring 3 is composed of two fan pieces 3.1, the flange 3.2 and the opening method It is also the same as the first embodiment, after the sector ring 3 is fixed on the first mounting plate 1, there is a gap of about 3 mm between the two sector pieces 3.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com