Burner for ranges

A burner and burner head technology, applied in the direction of burners, burners, burner safety devices, etc., can solve the problems of cutting time and cost increase, etc., achieve good fire mobility, prevent backfire, and prevent errors The effect of setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

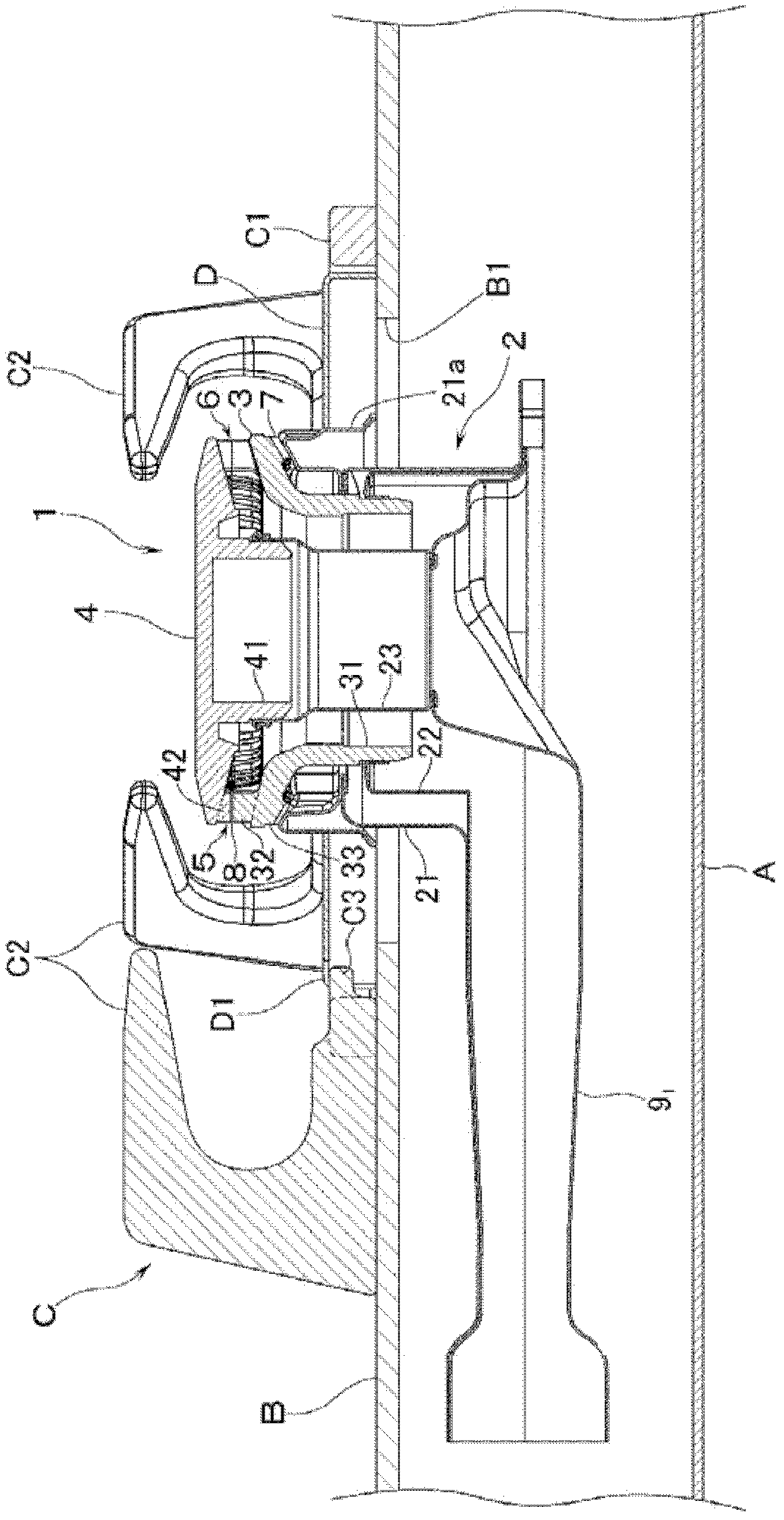

[0036] refer to figure 1 , A is the main body of the stove, B is the top plate covering the upper surface of the main body A of the stove, and the burner opening B1 opened on the top plate B is provided close to the burner 1 for the stove. Moreover, the flame stay C is mounted on the top board B so that the opening B1 for burners may be surrounded. And, the cooking vessel mounted on the fire stand C is heated by the burner 1 . In addition, the fire prop C includes a ring-shaped fire prop frame C1 and a plurality of fire prop claws C2 radially installed on the fire prop frame C1.

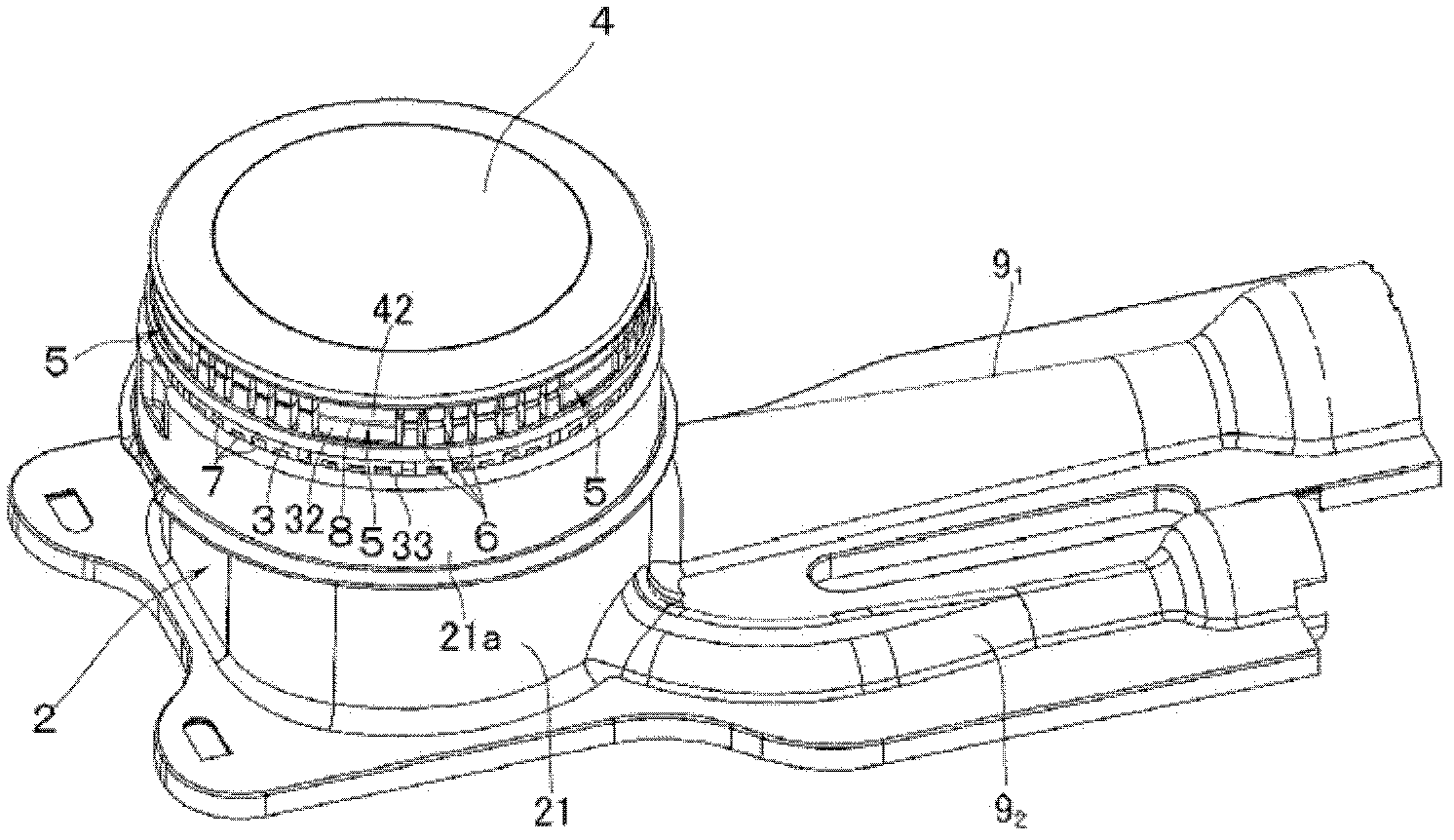

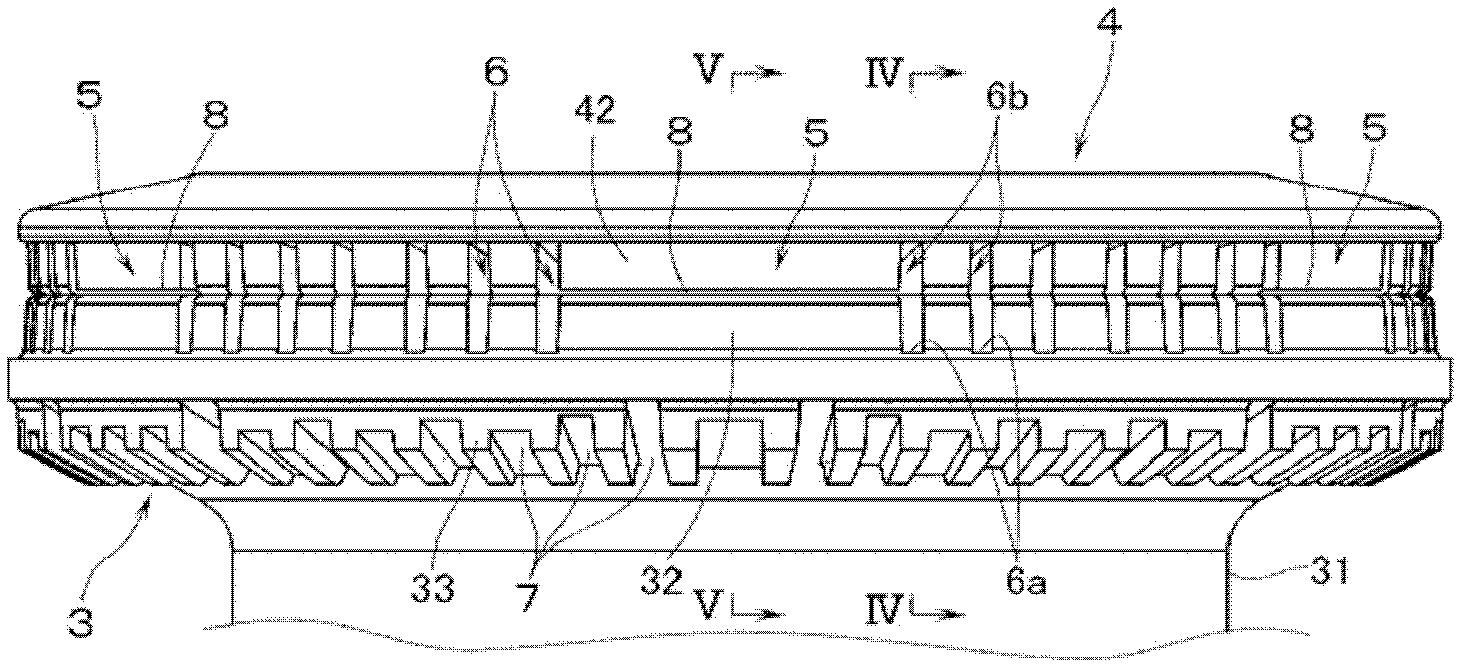

[0037] The burner 1 includes: a sheet metal burner body 2 inserted through the burner opening B1; a burner head 3 provided on the burner body 2 and made of a metal casting or forging such as brass; And the burner cover 4 provided on the burner head 3 is made of a metal casting or forging such as brass. Such as figure 2 As shown, in the outer peripheral portion between the burner head 3 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com