Wheel arranging device for steel cord outer winding machine and wheel arranging method thereof

A technology of outer winding machine and steel cord, which is applied in the direction of hoisting device, transportation and packaging, spring mechanism, etc., and can solve the problems of affecting production efficiency, heavy weight, slipping and bruising, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

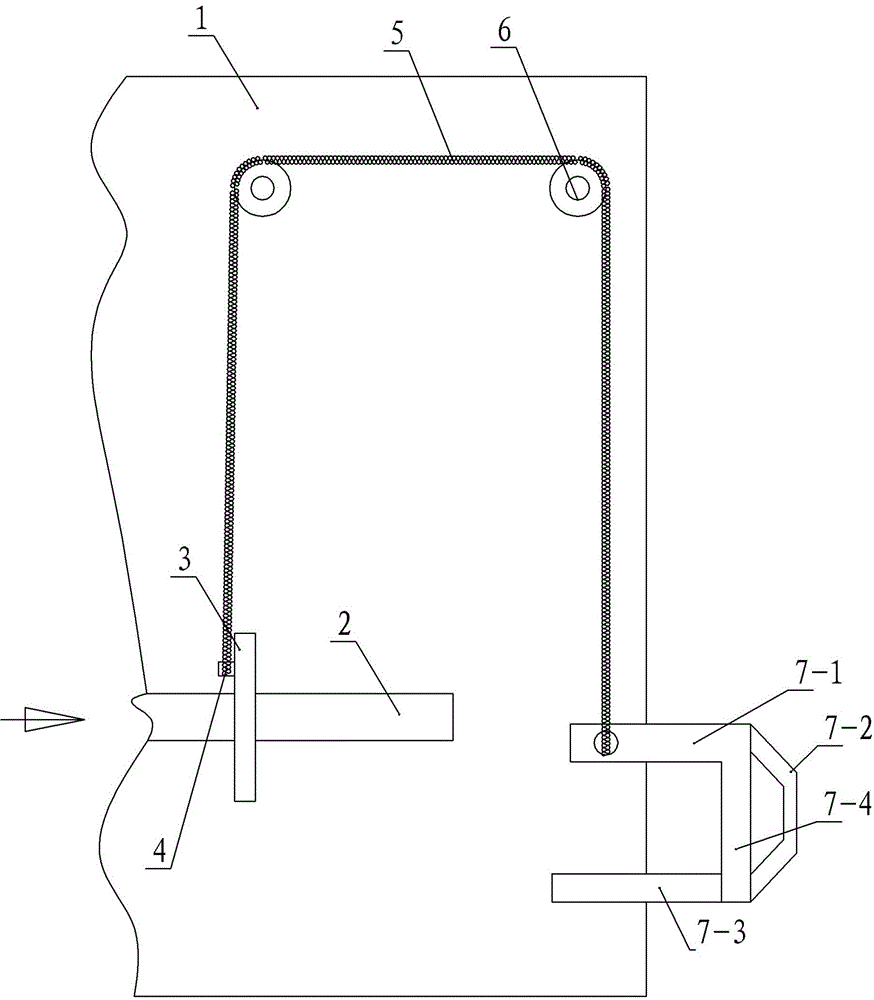

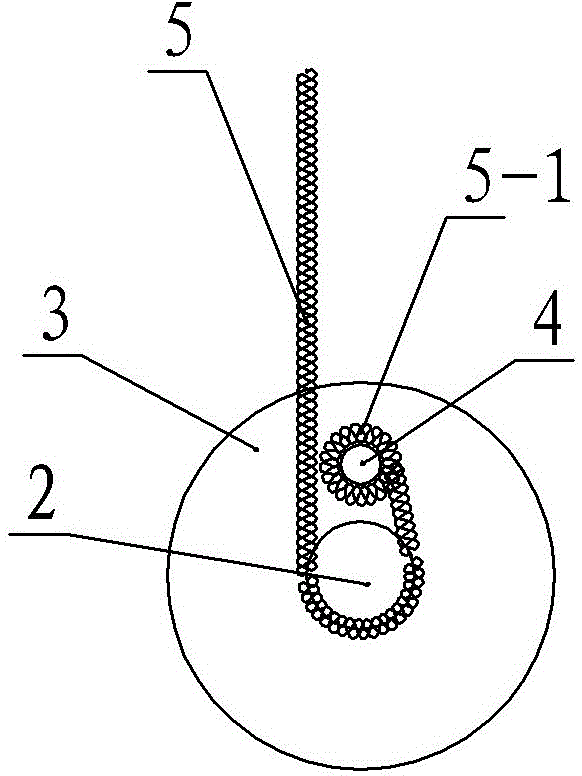

[0019] Embodiment one: see figure 1 , figure 2 , a steel cord outer winding machine upper wheel device in the figure, including the steel cord outer winding machine's own pay-off shaft and two guide wheels on the upper part of the pay-off shaft, the pay-off shaft is connected with the power unit, and the pay-off A reel is provided on the shaft, and a hook is provided on the reel. The upper wheel device also includes a flexible suspension rope and a wheel fork. One end of the flexible suspension rope is connected to the wheel fork, and the other end is provided with a rope sleeve. , the rope sleeve is hung on the hook on the reel, and the middle part of the flexible sling is hung on the two upper guide wheels. The wheel fork includes an inner rod and an outer rod, the ends of both sides are connected by a vertical rod, and a handle is provided on the outside of the vertical rod; the end of the flexible suspension rope is connected to the outer rod. Of the two guide wheels, o...

Embodiment 2

[0020] Embodiment two: see figure 1 , figure 2 , a method for loading wheels on a steel cord outer winding machine, the steel cord outer winding machine is provided with a pay-off shaft and two guide wheels on the upper part of the pay-off shaft, the pay-off shaft is connected with a power unit, and the pay-off shaft is Provided with a reel, the method also requires a fork and a flexible sling, comprising the following steps,

[0021] ①. Insert the wheel fork into the shaft hole of the I-shaped wheel first, then connect one end of the flexible sling to the wheel fork, and the other end of the flexible sling to the reel, and finally put the middle of the flexible sling on the on the two guide wheels;

[0022] ②. Start the power device of the steel cord outer winding machine, drive the pay-off shaft to rotate, drive the winding wheel to rotate, and gradually wind the flexible sling on the anti-spool, so that the wheel fork and the I-shaped wheel connected to the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com