Spherical workpiece placement device

A workpiece and spherical technology, which is applied in the field of spherical workpiece shelving devices, can solve problems such as displacement, personal injury, and easy rolling, and achieve the effects of simple device structure, improved production safety, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

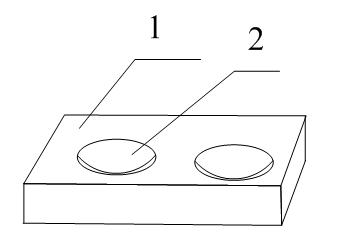

[0024] Such as figure 1 As shown, the spherical workpiece resting device includes a base 1 on which a hemispherical recess 2 is provided.

[0025] Preferably, the number of the recesses is two, and the upper surface of the recesses 2 is provided with patterns.

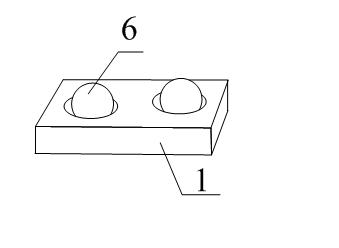

[0026] In use, the spherical workpiece is placed in the hemispherical recess. The two are attached to each other, so displacement is not easy to occur; that is, the spherical workpiece can be restricted in a certain position.

Embodiment 2

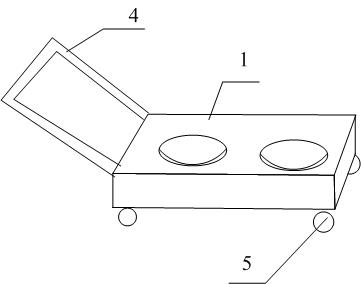

[0028] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that casters 5 are provided under the base, and a push handle 4 is provided on one side of the base.

[0029] The setting of the casters and the push handle can facilitate the handling of the workpieces stored on the spherical workpiece shelving device.

[0030] During specific implementation, gauze may also be laid on the upper surface of the concave portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com