Cover board installation structure for a construction site

A construction site and installation structure technology, which is applied in building construction, construction material processing, construction, etc., can solve the problems of excessive manpower and time consumption, low reuse rate, and increased construction costs, so as to save time and manpower , Reduce the required quantity and save the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the preferred embodiments of the present invention will be described in detail in conjunction with the accompanying drawings, but in the drawings, the same structures are marked with the same symbols as much as possible, and, in order not to confuse the gist of the present invention, specific details on related disclosed technologies or functions are omitted. illustrate.

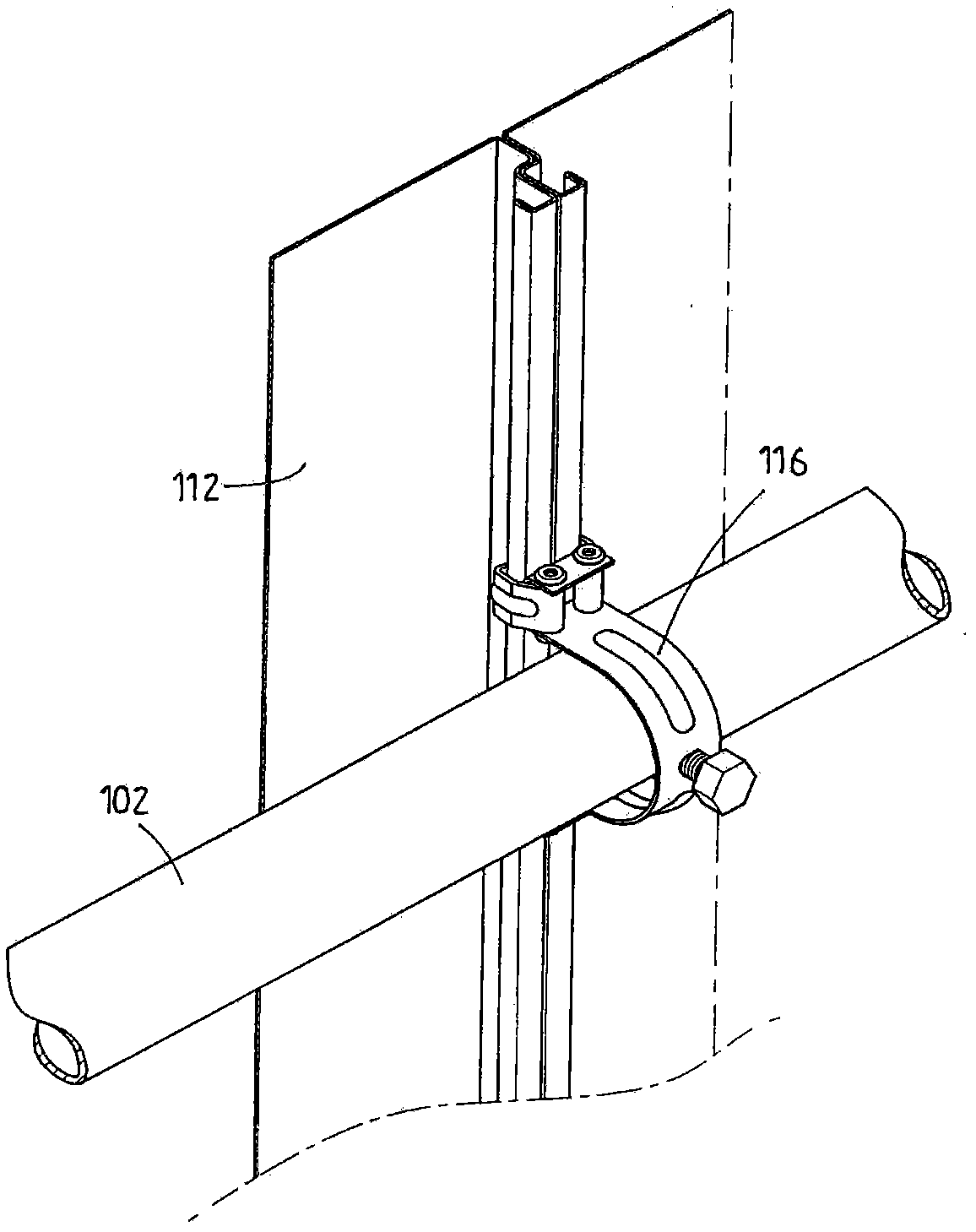

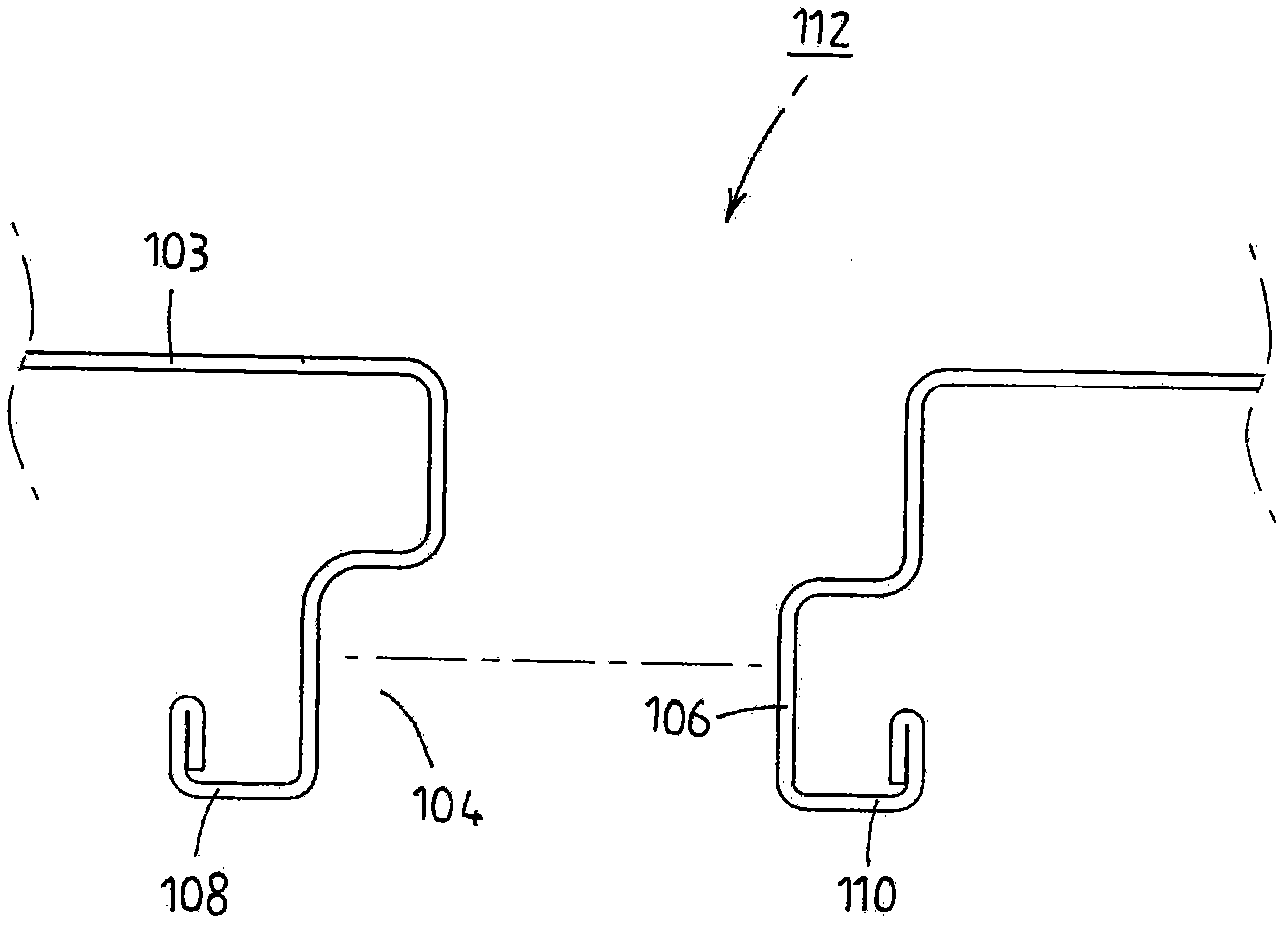

[0028] Figure 5 It is a schematic diagram of an important part of the present invention. The present invention is vertically fixed at a certain interval on the H-pillar 10 between the construction site and the sidewalk, and a plurality of scaffolding rods 12 are horizontally connected and fixed at an appropriate interval up and down, while the above-mentioned scaffolding rods In front of 12, a plurality of panels 20 formed by bending metal plates are combined side by side, so that each adjacent left and right panel 20 is tightened and fixed at the same time through a plurality of clips 40 each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com