Composition for inhibiting calcium salt scale formation

A composition, calcium salt technology, applied in the direction of preventing corrosion/sediment formation of pulping equipment, regeneration of pulping liquid, descaling and water softening, etc., can solve problems such as not improving calcium carbonate inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

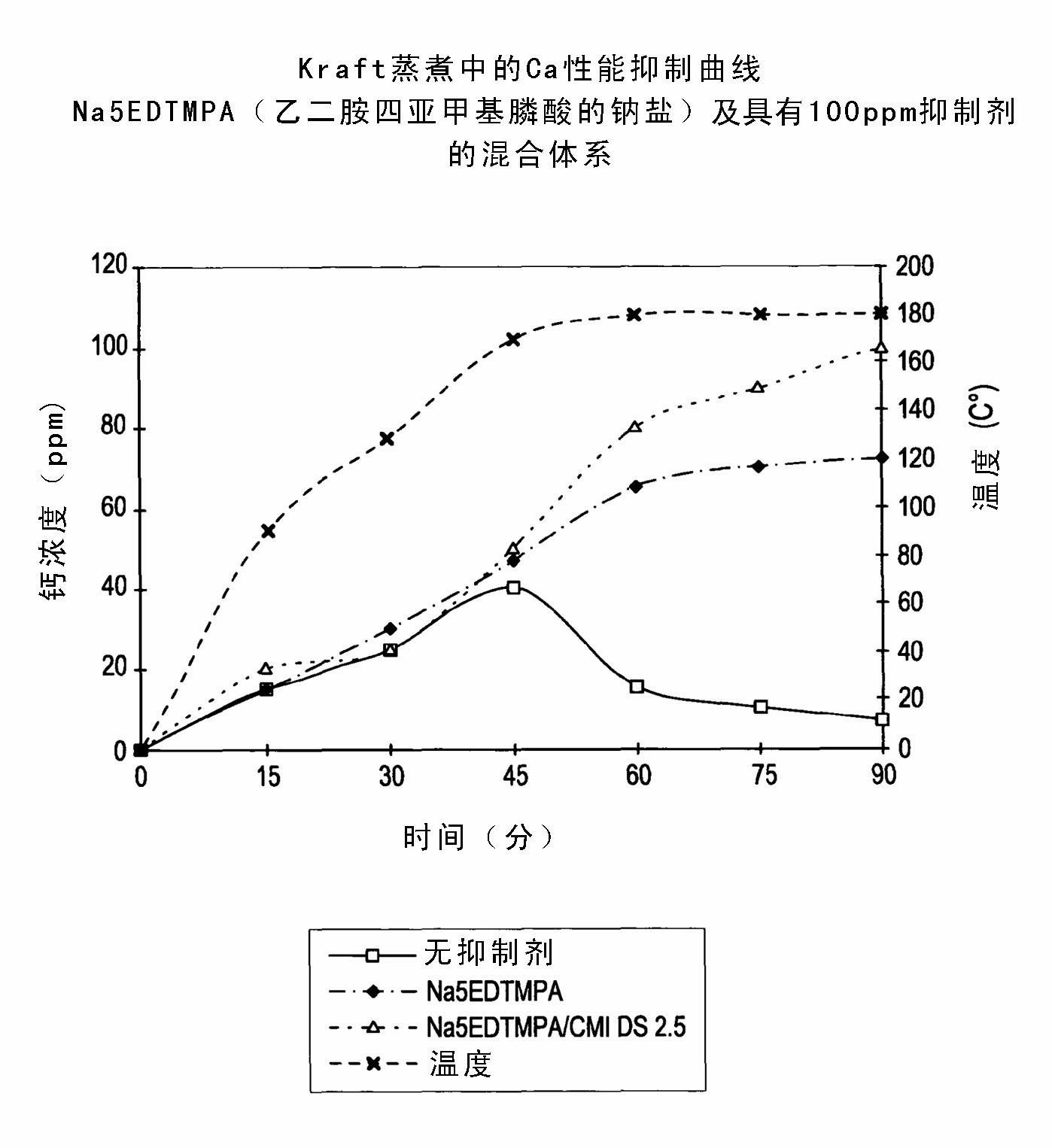

[0095] The scale inhibiting composition consisted of the sodium salt of ethylenediaminetetramethylenephosphonic acid as the first component and carboxymethyl inulin having a DS of 2.5 as the second component.

[0096] METHODS: Kraft cooking was performed in a MK Systems (Danvers, Massachusetts) 6L digester with an extractor port and condenser added to the digester to allow the sample to be pulled while the system was under pressure. Conditions used in Kraft cooking included a 5:1 liquor to wood ratio, 18.5% available alkali, 25% sulfidation and varying levels of Na 2 CO 3 , and 5g / L as the most commonly tested concentration. 10% (v / v) H before each Kraft cooking 2 SO 4 The aqueous solution was circulated in the digester for 10 minutes to remove any sediment present. The acid solution was drained and the digester was rinsed several times with deionized water. Add 4 L of white liquor (as above) to the digester and record the initial temperature. 800 g of oven dried pine ch...

Embodiment 2

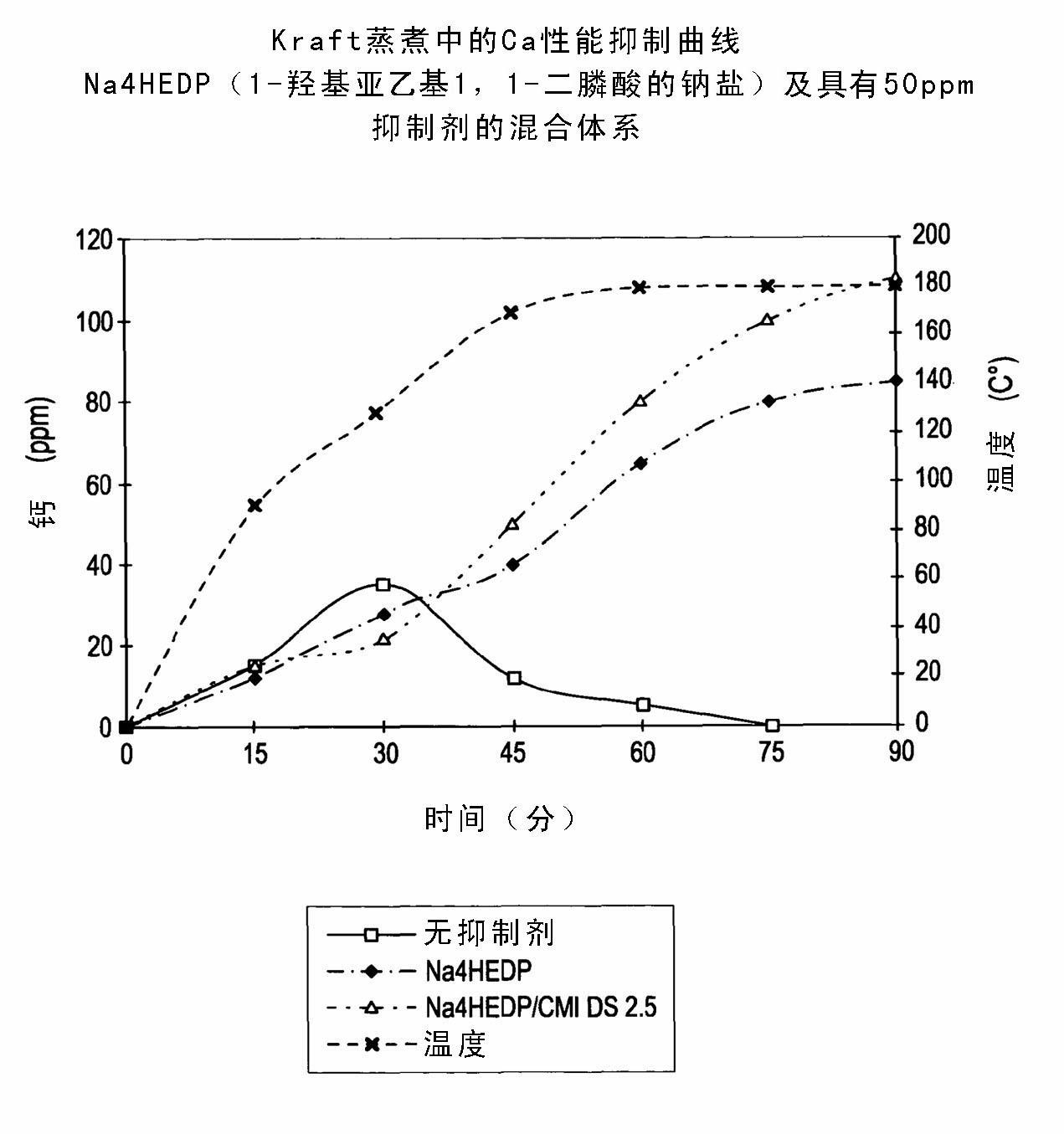

[0101] The scale inhibiting composition consisted of the sodium salt of 1-hydroxyethylidene (1,1-diphosphonic acid) as the first component and carboxymethyl inulin with a DS of 2.5 as the second component.

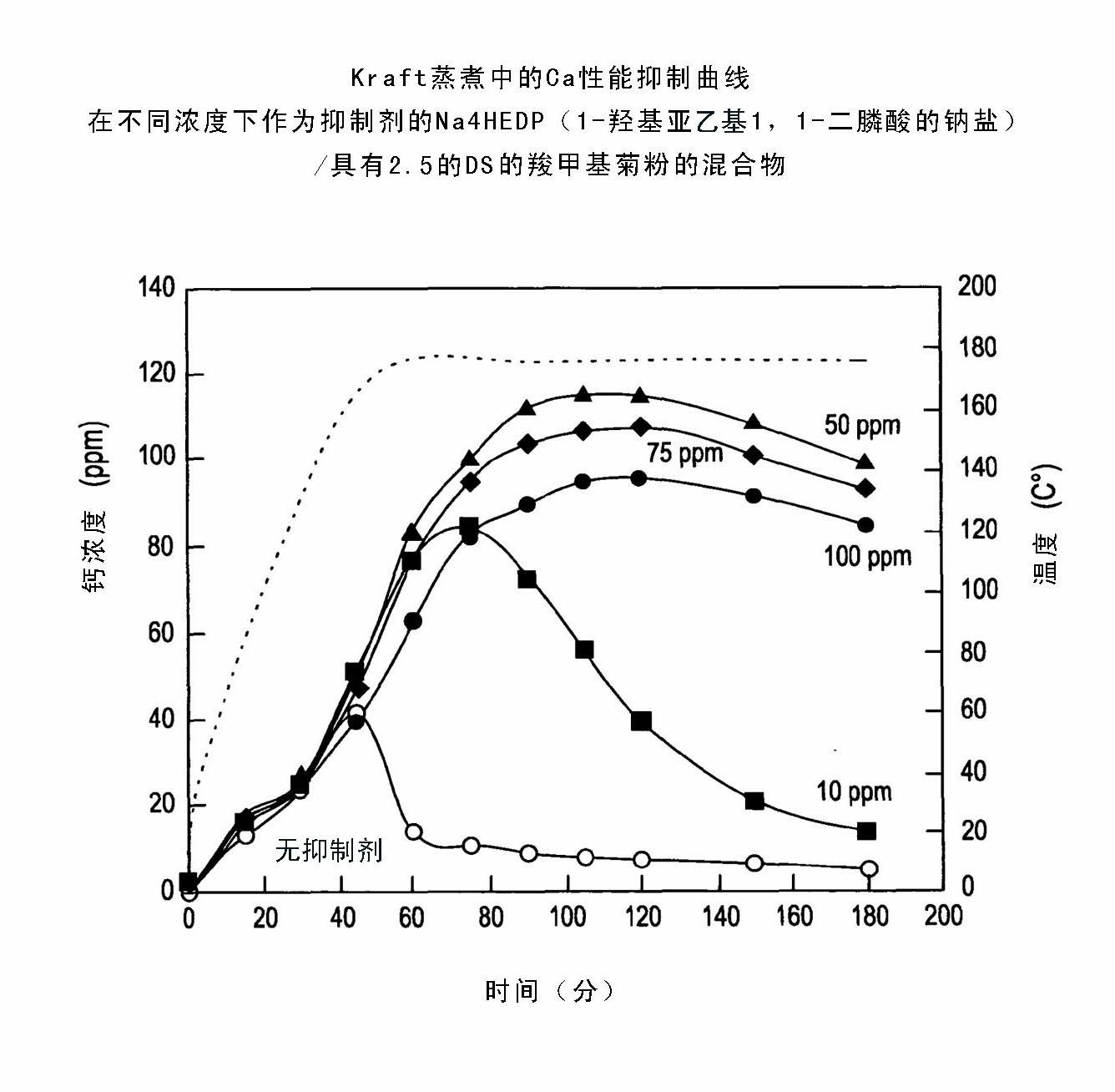

[0102] Method: same as Example 1. result in image 3 shown in .

[0103] As can be clearly seen from the laboratory test data and factory test results described in the examples, the mixed product is composed of the specific organometallic phosphonate component of the present invention and carboxylated fructan components, when combined with excluding fruit Calcium carbonate inhibition was increased by at least 20% when compared to the product of the glycan fraction. Furthermore, the test data demonstrate comparable performance at levels between 50 ppm and 100 ppm when the organometallic phosphonate component is combined with the carboxylated fructan component. This result indicates that if a decrease in performance was observed when the dosage was increased, then due to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com