Phase isolated cast tubular bus and preparation method thereof

A technology of pipe busbar and pouring pipe, which is applied in the field of power transmission and distribution, can solve the problems that it is difficult to meet the requirements of full busbar closure, bubbles in the resin insulation layer, and affect insulation performance, etc., to facilitate manufacturing and installation, reduce quantity, and carry current powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

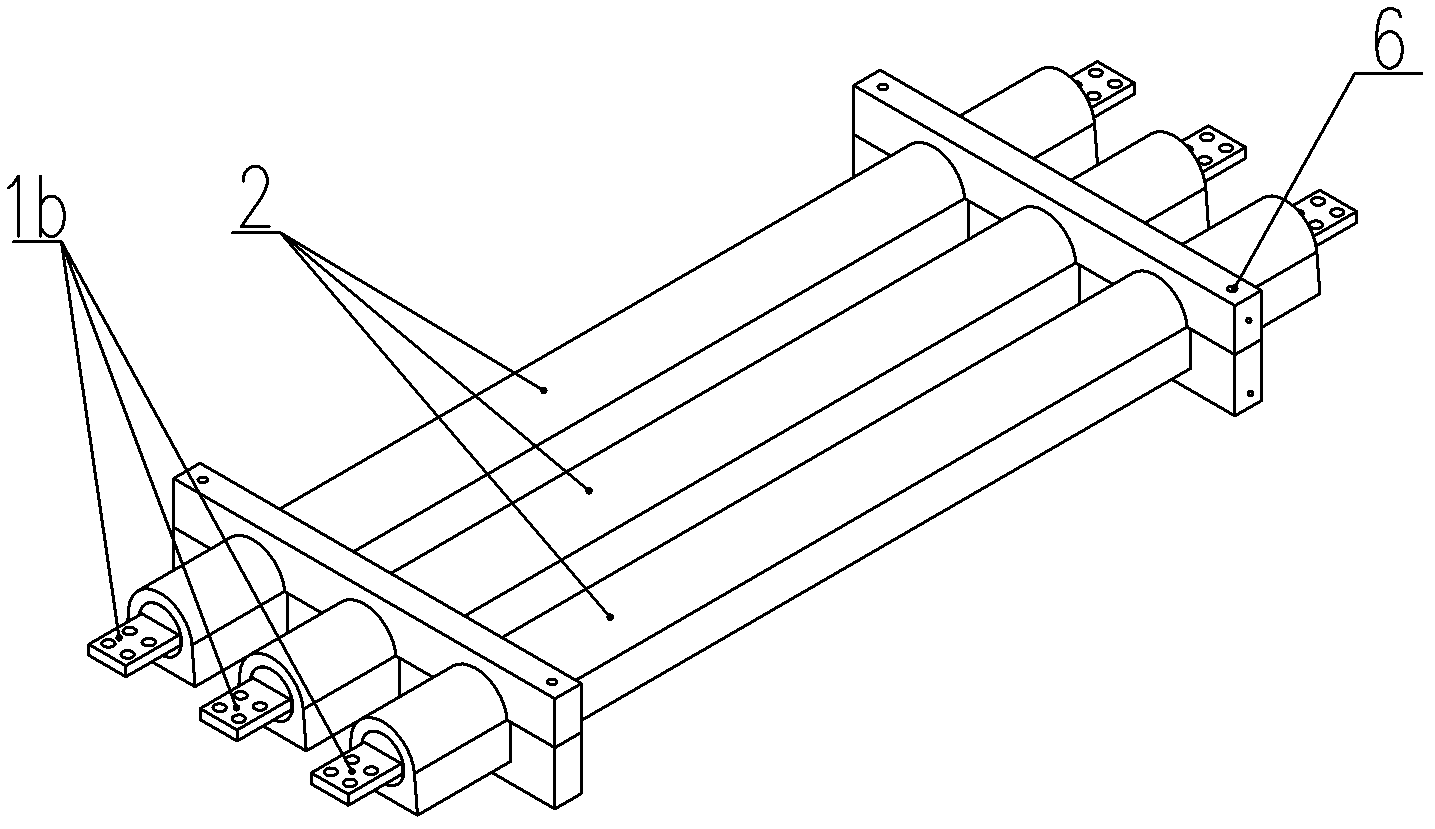

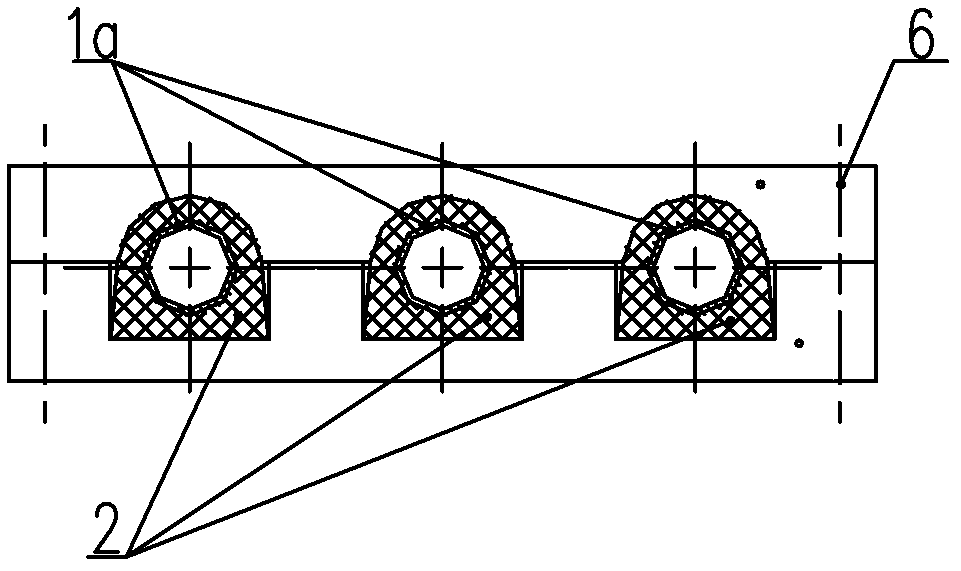

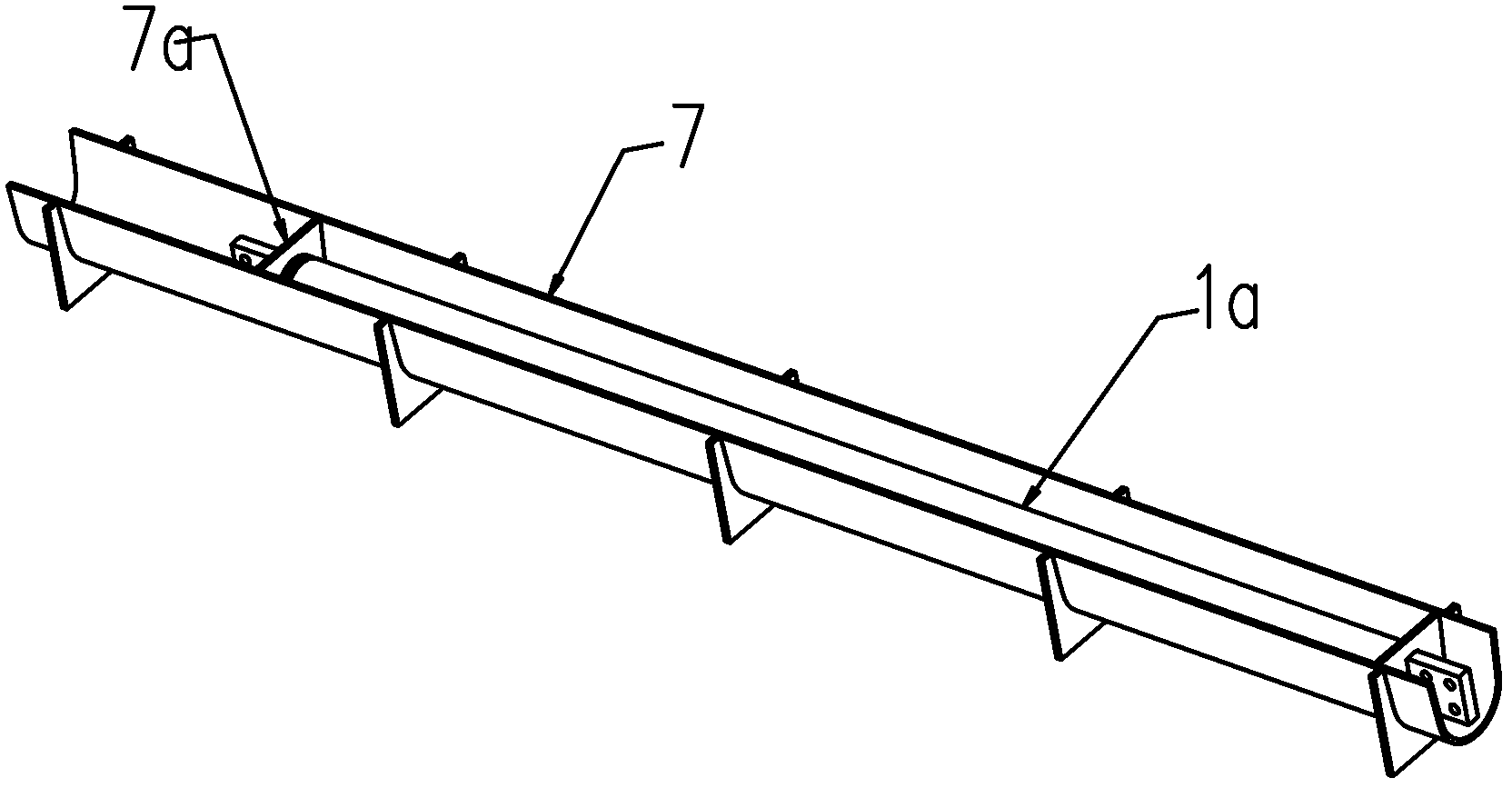

[0030] The out-of-phase pouring pipe busbar of this embodiment is as follows figure 1 and figure 2 As shown, the two ends of the segmented pipe bus main body 1a have pressed flat joints 1b, and the two flat joints are respectively located on both sides of the diameter section in the length direction of the pipe bus, so that when the adjacent pipe bus main bodies are docked, they can maintain adjacent pipe bus The main body is coaxial. The main body 1a of the pipe bus bar is cast with a resin insulating layer 2. The cross-sectional outline of the insulating layer 2 consists of a circular arc segment 2a concentric with the pipe bus bar, an extended straight line segment 2b tangent to both sides of the arc segment, and a line intersecting the two extended straight lines. A horizontal straight line segment 2c is formed. The length of the horizontal straight line segment 2c is greater than the diameter of the circular arc segment 2a, so the drafting slope can be formed, which is...

Embodiment 2

[0042] The out-of-phase pouring pipe busbar of this embodiment is as follows Figure 8 and Figure 9 As shown, the difference from Embodiment 1 is that the insulating layer of the main body of a group of pipe busbars does not form a line-by-line separated phase structure through two pairs of supporting frames 6, but through an upper part with a recess that matches the cross section of the insulating layer. , middle and lower 3a, 3b, 3c are combined with the support frame 6 to form a character-shaped out-of-phase structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com