Detection method for rotation speed of roller of washing and dehydration machine and detection unit structure thereof

A drum rotation speed and detection method technology, applied in the direction of linear/angular velocity measurement, velocity/acceleration/impact measurement, measuring device, etc., can solve problems such as poor adaptability, affecting the performance and life of the washer-extractor, and achieve stable operation maintenance, Achieve quick response and reduce washing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

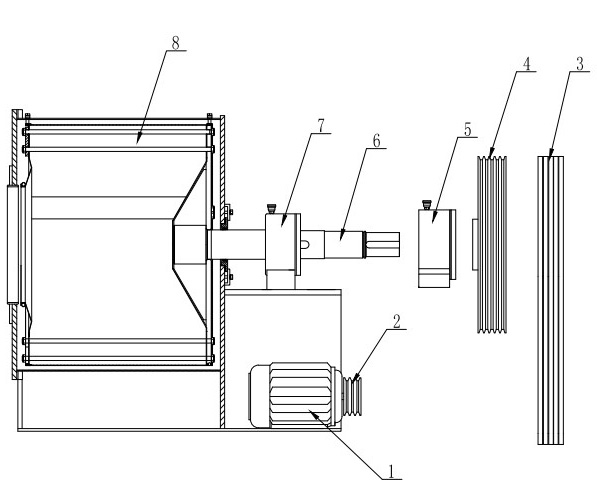

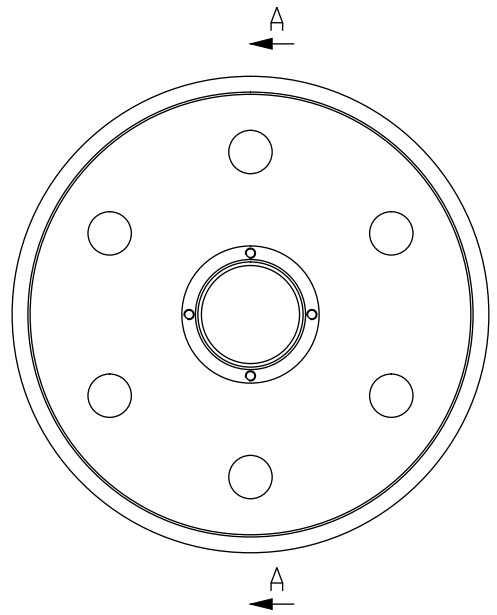

[0024] like Figure 2a and Figure 2b As shown, six load-relief holes are evenly distributed on the circumference of the wheel surface of the large pulley 4, and the speed sensor 9 is installed in the air relative to the wheel surface, and coincides with the circle formed by the center of the load-relief holes on the large pulley. When rotating, a pulse signal proportional to the rotational speed is generated between the rotational speed sensor and the wheel surface due to the relative movement of the unloading hole.

[0025] Although the number of load-relief holes in this embodiment is six, in the actual application process, the number can be set arbitrarily according to actual needs, generally more than two, and these load-relief holes are coaxial and evenly distributed on the circumference driven wheel face.

Embodiment 2

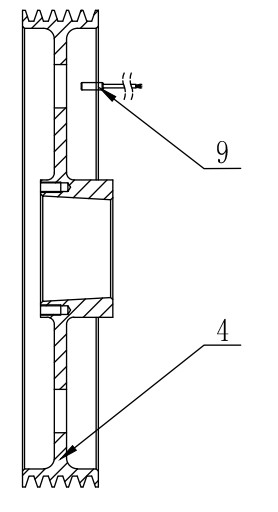

[0027] like Figure 3a and Figure 3b As shown, on the central shaft 6, there is a keyway with a concave opposite surface, and the sensor is installed on the axial center plane of the keyway close to the shaft surface. When the central shaft 6 rotates, the gap between the speed sensor and the shaft surface is due to The keyway changes, and a pulse signal proportional to the shaft speed is obtained.

[0028] Through the above overview, detailed description and embodiment introduction in conjunction with the accompanying drawings, the features of the detection method and its detection unit structure of the present invention should have been fully demonstrated and easy to understand. And implementing the technical scheme of the present invention, its significant technical progress is reflected in: provide the real-time detection input for the real-time control of washing machine, can solve the motor stall that load changes cause, realize the fast response of forward and reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com