Automation storage yard laser measurement device and application method thereof

A laser measurement and stockyard technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of no stockyard coordinate system, increased cost, complicated use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

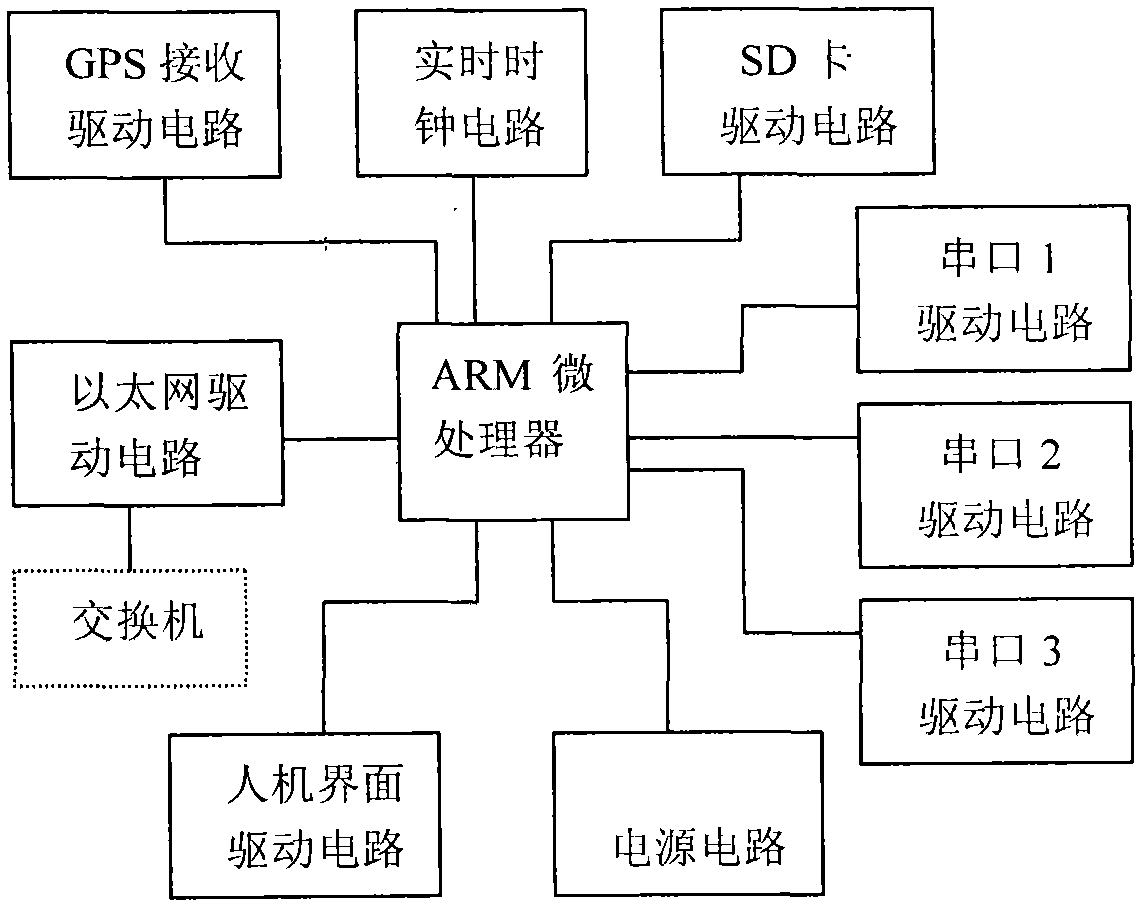

[0070] An automated yard laser measuring device, comprising:

[0071] Synchronous control collector: used to control all sensors, obtain collected data from sensors, and realize remote control and data transmission at the same time;

[0072] A laser scanner connected to the synchronous control collector: used to scan the stockyard section;

[0073] Simultaneously, the horizontal displacement sensor connected with the synchronous control collector and the laser scanner: obtain the walking distance of the scanner when the laser scanner scans the stockyard section in real time;

[0074] The horizontal rotation sensor connected with the synchronous control collector and the laser scanner at the same time: obtain the angle between the scanner and the track when the laser scanner scans the yard section in real time;

[0075] Simultaneously with the vertical displacement sensor that described synchronous control collector and laser scanner are connected: obtain the included angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com