Method for purifying hydrogen peroxide

A technology of hydrogen peroxide and purification tower, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of high purification cost, increased Problems such as large labor power, waste of raw materials, equipment blockage and cleaning, etc., to improve product quality and improve the effect of containing more organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Put 100ml of crude hydrogen peroxide obtained after extraction and the mixed solvent into a 500ml beaker, stir and mix at 100 rpm for 5 minutes, then stand still for 10 minutes to separate layers, and keep the temperature of the solution at 30-50°C Between, measure the organic carbon content in the hydrogen peroxide obtained after delamination. The organic carbon analyzer used is TOC-V-CPN from Shimadzu, Japan.

[0010] The mixed solvents prepared are respectively heavy aromatics and trioctyl phosphate, which are put in a beaker and stirred evenly.

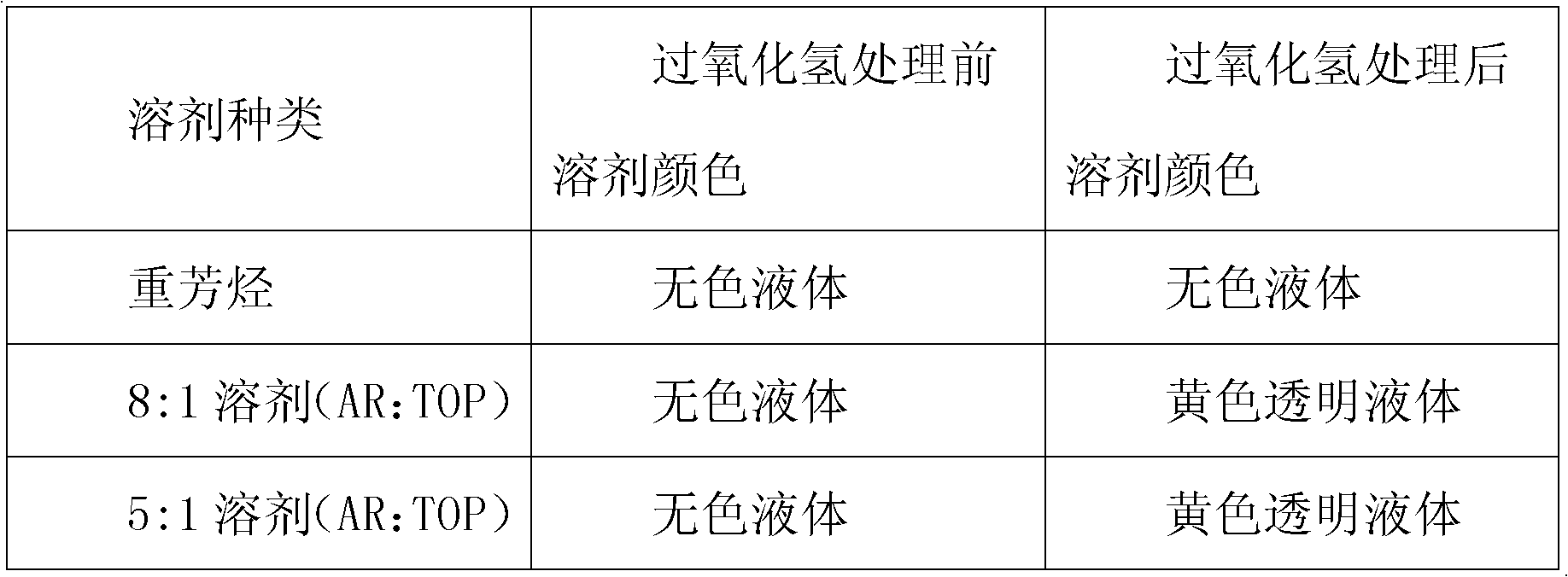

[0011] Table 1 The color change of hydrogen peroxide treated with different solvents

[0012]

[0013] The two solvents are used in the purification of crude hydrogen peroxide after the ratio, and the color change of the solvent can be clearly seen from the appearance of the hydrogen peroxide obtained after the treatment. It shows that more anthraquinones are dissolved into the mixed solvent.

Embodiment 2

[0015] Put 100ml of crude hydrogen peroxide obtained after extraction and the mixed solvent into a 500ml beaker, stir and mix at 100 rpm for 5 minutes, then stand still for 10 minutes to separate layers, and keep the temperature of the solution at 30-50°C Between, measure the organic carbon content in the hydrogen peroxide obtained after delamination. The organic carbon analyzer used is TOC-V-CPN from Shimadzu, Japan.

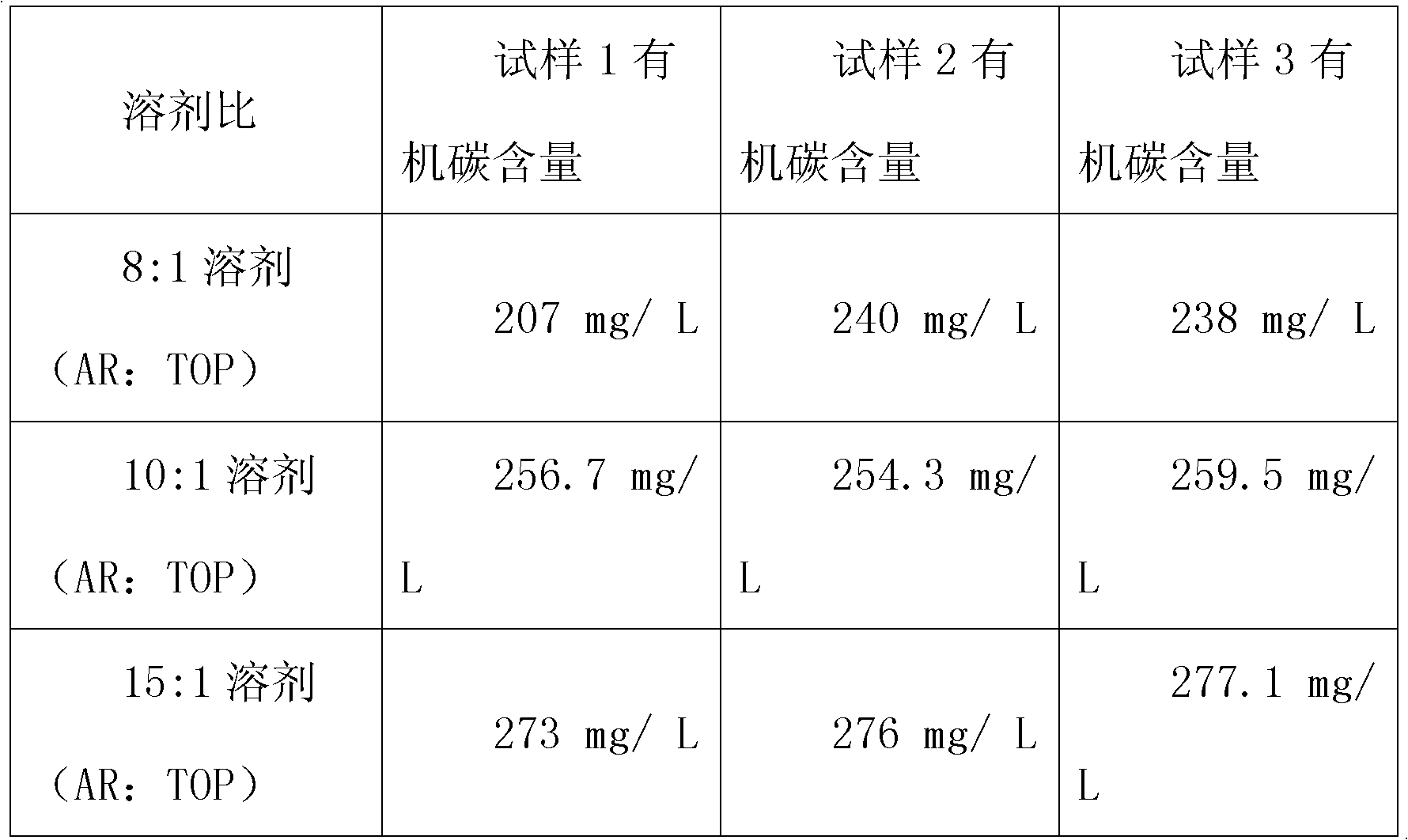

[0016] Make the mixed solvents of different ratios in Table 2 with heavy aromatics and trioctyl phosphate, and add 3 parts of mixed solvents per 100 parts of hydrogen peroxide to process the crude hydrogen peroxide obtained in the extraction tower.

[0017] Table 2 Treatment results of 300ml hydrogen peroxide and 15ml mixed solvent according to different solvent ratios

[0018] The organic carbon content in the crude hydrogen peroxide obtained from the extraction tower is 560ppm, and the hydrogen peroxide contains 364.4ppm organic carbon after being purified b...

Embodiment 3

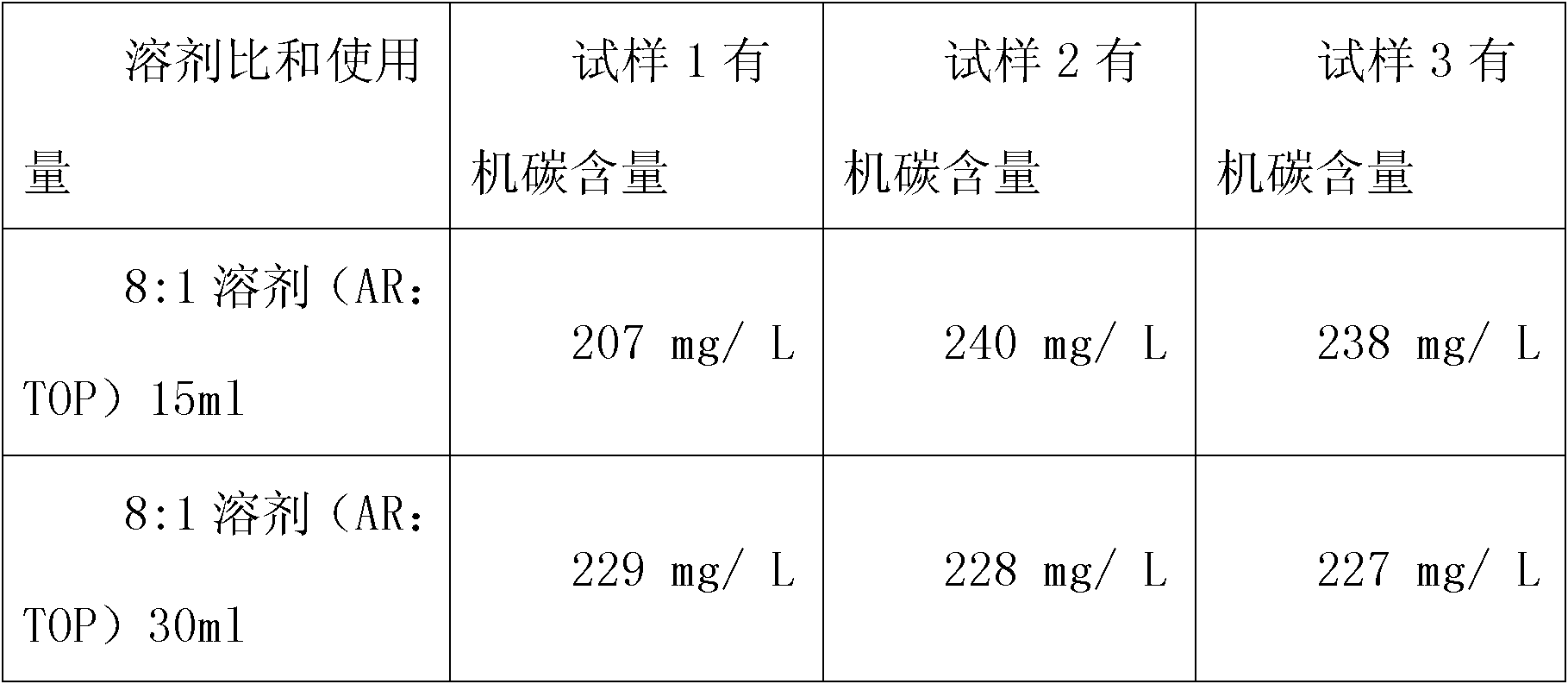

[0022] Make the mixed solvents of different ratios in Table 3 with heavy aromatics and trioctyl phosphate, and add 15 parts and 30 parts of mixed solvents to process the crude hydrogen peroxide obtained in the extraction tower for every 100 parts of hydrogen peroxide.

[0023] Table 3 Treatment results of different solvent dosages

[0024] The organic carbon content in the crude hydrogen peroxide obtained from the extraction tower is 560ppm, and the organic carbon content in the hydrogen peroxide after purification by heavy aromatics is 344.4ppm.

[0025]

[0026] It can be seen from the data in Table 3 that the crude hydrogen peroxide obtained in the extraction tower is purified by the mixed solvent, which can reduce the organic carbon content in the crude hydrogen peroxide more than that of heavy aromatics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com