Pallet put-away machine

A stacker and pallet technology, which is used in the stacking, transportation and packaging of objects, can solve the problems of difficulty in meeting production requirements, low labor efficiency, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

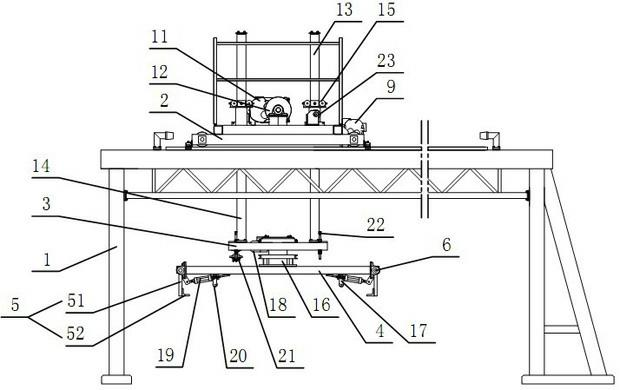

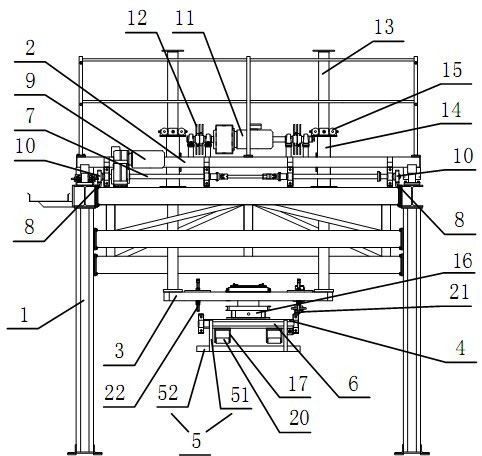

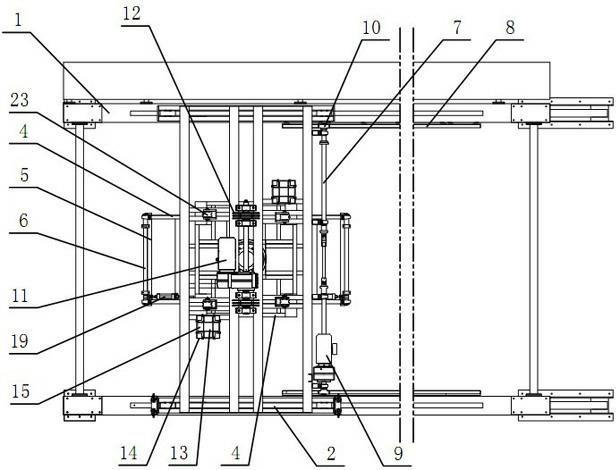

[0018] Such as figure 1 , figure 2 with image 3 The shown pallet stacking machine includes a frame 1, a slideway is fixedly installed on the frame 1, and the walking frame 2 is slidably connected to the slideway through rollers. In order to ensure the stability of the walking frame 2, the walking frame 2 can also be equipped The structure of the clamping wheel for clamping the slideway is a prior art and will not be repeated here. The walking frame 2 is driven by a walking power device, which includes a walking shaft 7 that is rotatably installed on the walking frame 2, and the walking shaft 7 is driven by a walking motor 9 installed on the walking frame 2, and the frame 1 is fixed with teeth Bar 8, the gear 10 that meshes with rack 8 is installed on the walking shaft 7. The walking frame 2 is connected with a lifting frame 3 which slides vertically, and the vertical sliding is realized through the following structure: the walking frame 2 is symmetrically fixed with four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com