Foaming device

A foamer and gas nozzle technology, applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of large foam diameter, poor effect of medicament or foaming agent, and unsatisfactory foam mineralization effect, so as to avoid clogging and The effect of being corroded, good foam mineralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

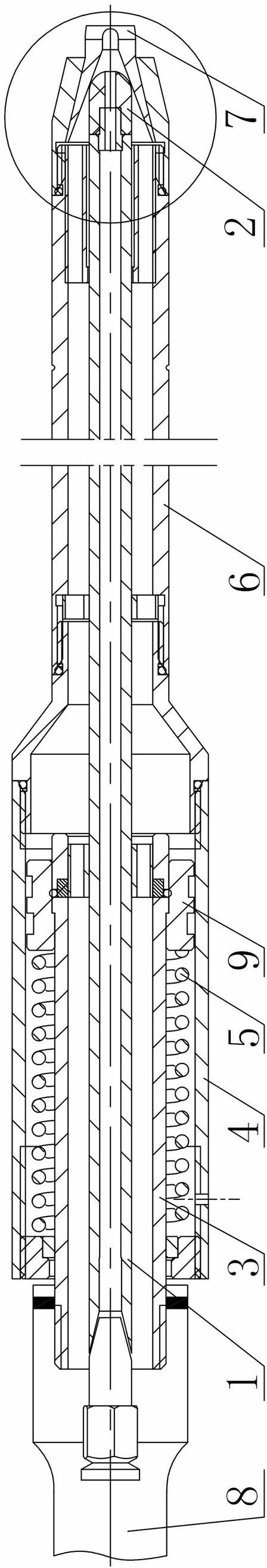

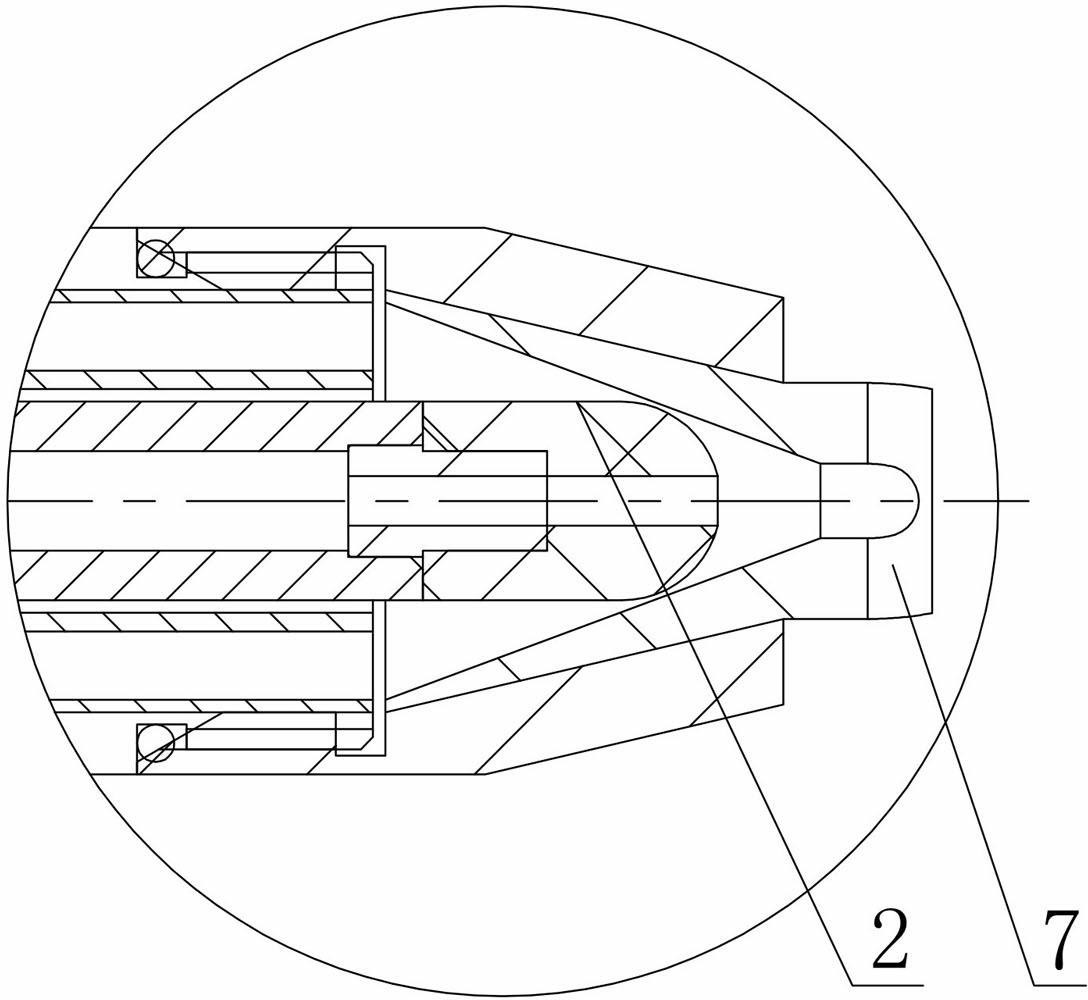

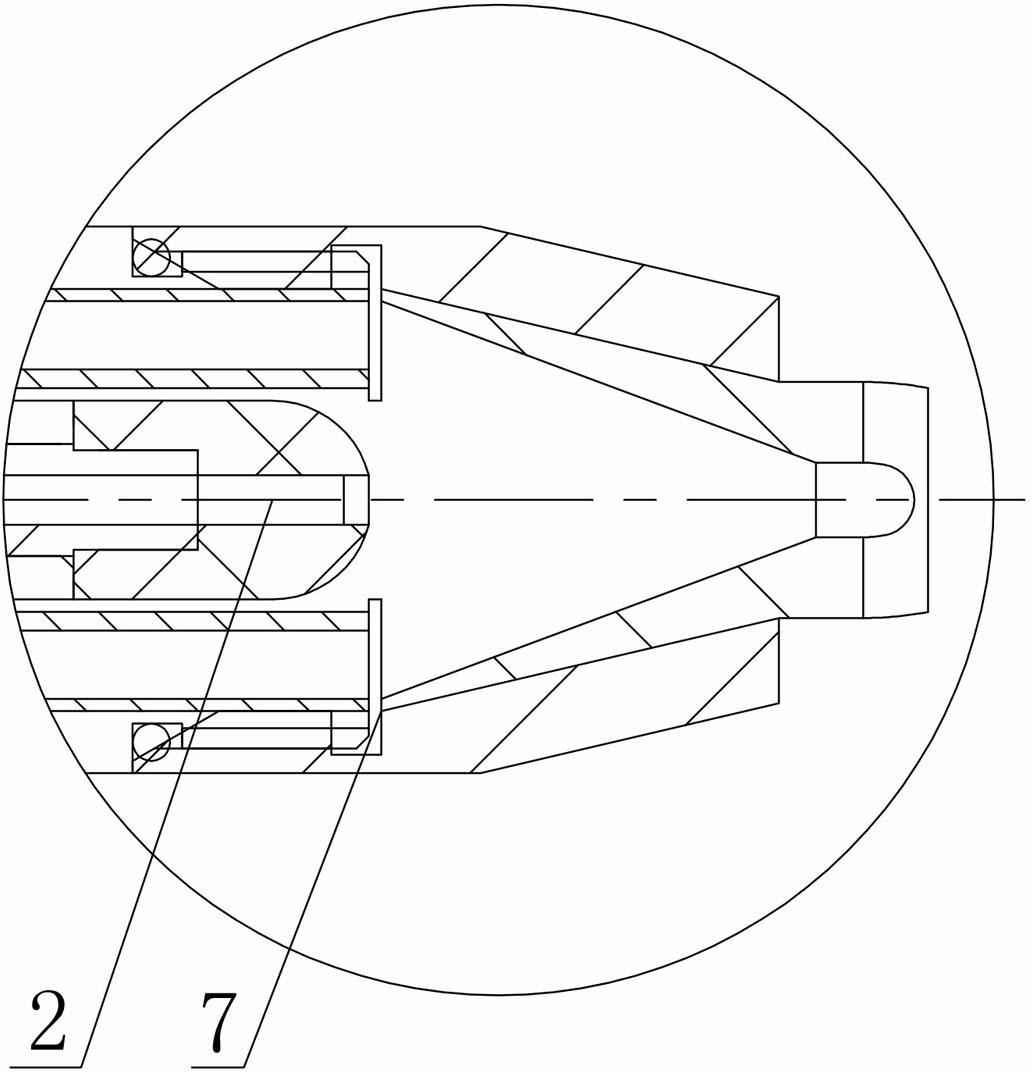

[0018] like figure 1 , figure 2 and image 3 As shown, the foamer of the present invention includes a liquid nozzle assembly and a gas nozzle assembly, the liquid nozzle assembly includes a liquid inlet pipe 1 and a liquid nozzle 2 positioned at the tail of the liquid inlet pipe 1, and the gas nozzle assembly includes an air inlet pipe 3 and a gas nozzle 7 , The liquid inlet pipe 1 is sleeved in the air inlet pipe 3 in a coaxial shape. The ejection direction of liquid and gas is the front, and the liquid nozzle 2 is located at the rear end of the gas nozzle 7 . The invention integrates the liquid nozzle assembly and the gas nozzle assembly, and adopts a nested design that cooperates with each other and does not interfere with each other, so that the liquid containing all kinds of medicaments and the high-pressure gas can be mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com