Method for recognizing flow state of granular material in raw coal bin of thermal power plant

A granular material and flow state technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems that various related data of granular materials cannot be directly monitored in real time, and the difficulty of testing the flow state of granular materials, etc. , to achieve the effect of solving the difficult problem of particle material flow measurement, high degree of intelligence, and simple signal acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

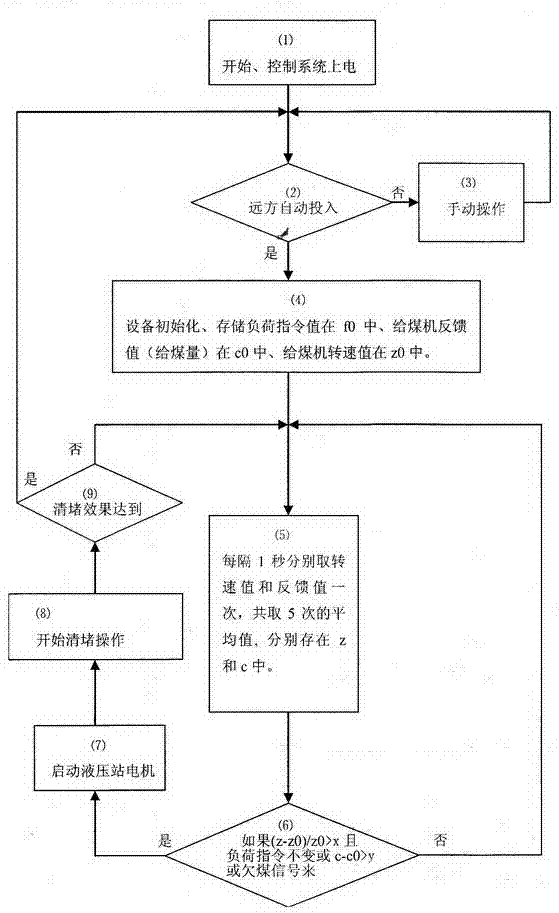

[0016] Concrete steps of the present invention are:

[0017] a. Start to power on, the electrical control cabinet controls the computer to start working, and detects the location and status of the hardware equipment;

[0018] b. Determine whether the control system is in the automatic running state. If it is in the automatic state, the program will go down to step d, otherwise perform manual operation. When there is no operation in the manual state, the software is always in the scanning state;

[0019] c. All the buttons on the control cabinet can be manually operated, and the actuator can be operated;

[0020] d. Store the initial state parameters of the controlled equipment in the computer, store the generator set load command value in f0, the coal feeder speed signal feedback value in c0, and the coal feeder speed signal value in z0, and judge the above signals , if the speed of the fuel conveyor is normal, return to cycle scanning, otherwise a control signal is sent to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com