Analysis method for observing shape of powdery sample by scanning electron microscope

An electron microscope and analysis method technology, applied in the direction of material analysis by measuring secondary emissions, scanning probe technology, instruments, etc., can solve the problems of powder flying polluting the mirror column and affecting observation, and achieve good contrast and high The effect of sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

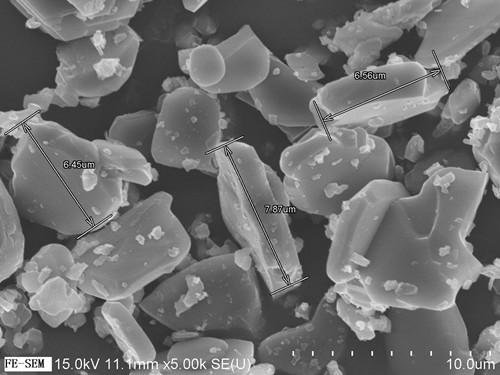

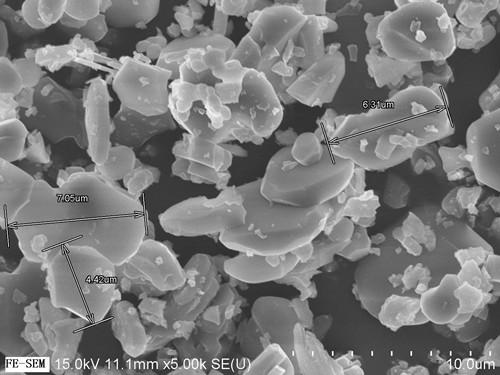

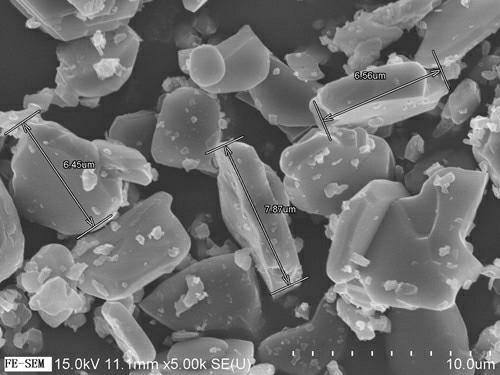

[0023] This example is for Al 2 O 3 The powder is subjected to morphology observation and analysis, and the specific operation steps are as follows:

[0024] A. Prepare the sample holder, and paste double-sided conductive copper glue on the holder;

[0025] B. Al 2 O 3 The powder sample was placed in a qualitative filter paper folded into a V shape, and the folded qualitative filter paper was shaken gently to make the Al 2 O 3 The powder sample slides down the surface of the conductive copper glue along the V-shaped groove;

[0026] C. Put the bracket and the powder sample in contact with the working table and vibrate several times, and use the inertia to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com