Pore gradient silicon carbide porous ceramic and preparation method thereof

A technology of gradient silicon carbide and porous ceramics, which is applied in the direction of ceramic products, other household utensils, household utensils, etc., can solve the problems affecting the use effect of porous ceramics, and achieve the effect of high ceramic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

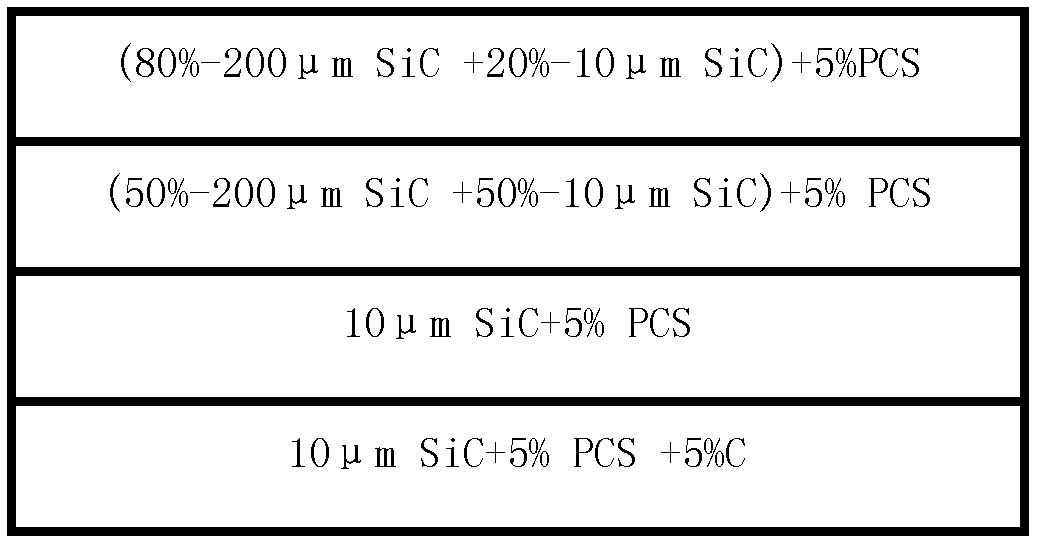

[0024] A method for preparing a pore-gradient silicon carbide porous ceramic, calculated with the total mass of added silicon carbide powder as 100 parts, the specific steps are:

[0025] 1) Add 20 parts of 10 μm fine silicon carbide powder, 80 parts of coarse silicon carbide powder and 5 parts of polycarbosilane into the xylene solution, then ball mill and mix for 3 hours to obtain a cloudy solution; then remove the solvent in the cloudy solution, Obtain silicon carbide powder coated with polycarbosilane, grind and pass through a 100-mesh sieve;

[0026] 2) Add 40 parts of 10 μm fine silicon carbide powder, 60 parts of coarse silicon carbide powder and 5 parts of polycarbosilane into the xylene solution, then ball mill and mix for 3 hours to obtain a cloudy solution; then remove the solvent in the cloudy solution, Obtain silicon carbide powder coated with polycarbosilane, grind and pass through a 100-mesh sieve;

[0027] 3) Add 100 parts of 10 μm fine silicon carbide powder ...

Embodiment 2

[0033] A method for preparing a pore-gradient silicon carbide porous ceramic, calculated with the total mass of added silicon carbide powder as 100 parts, the specific steps are:

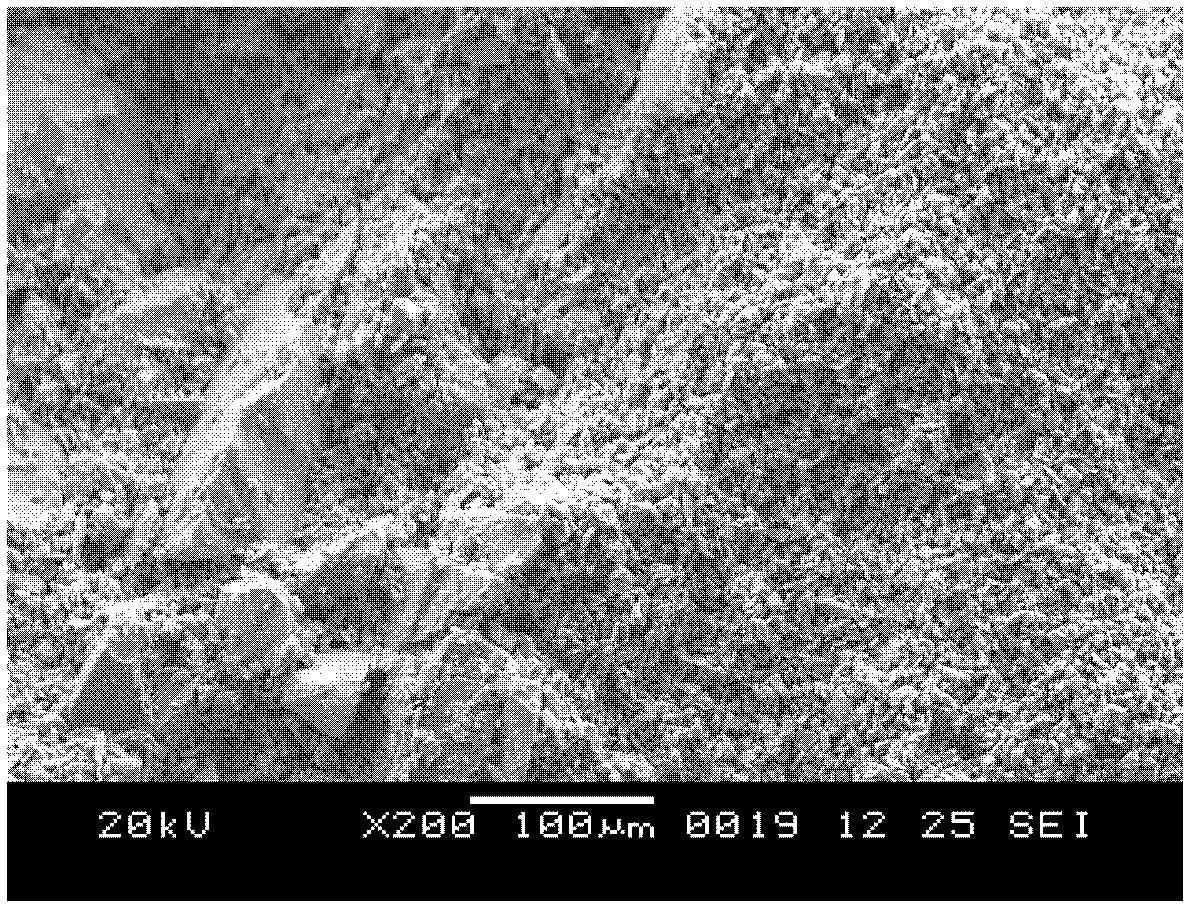

[0034] 1) Add 20 parts of 10 μm fine silicon carbide powder, 80 parts of coarse silicon carbide powder and 5 parts of polycarbosilane into the xylene solution, then ball mill and mix for 3 hours to obtain a cloudy solution; then remove the solvent in the cloudy solution, Obtain the silicon carbide powder that is coated with polycarbosilane, grind and cross 100 mesh sieves; figure 2 middle left part;

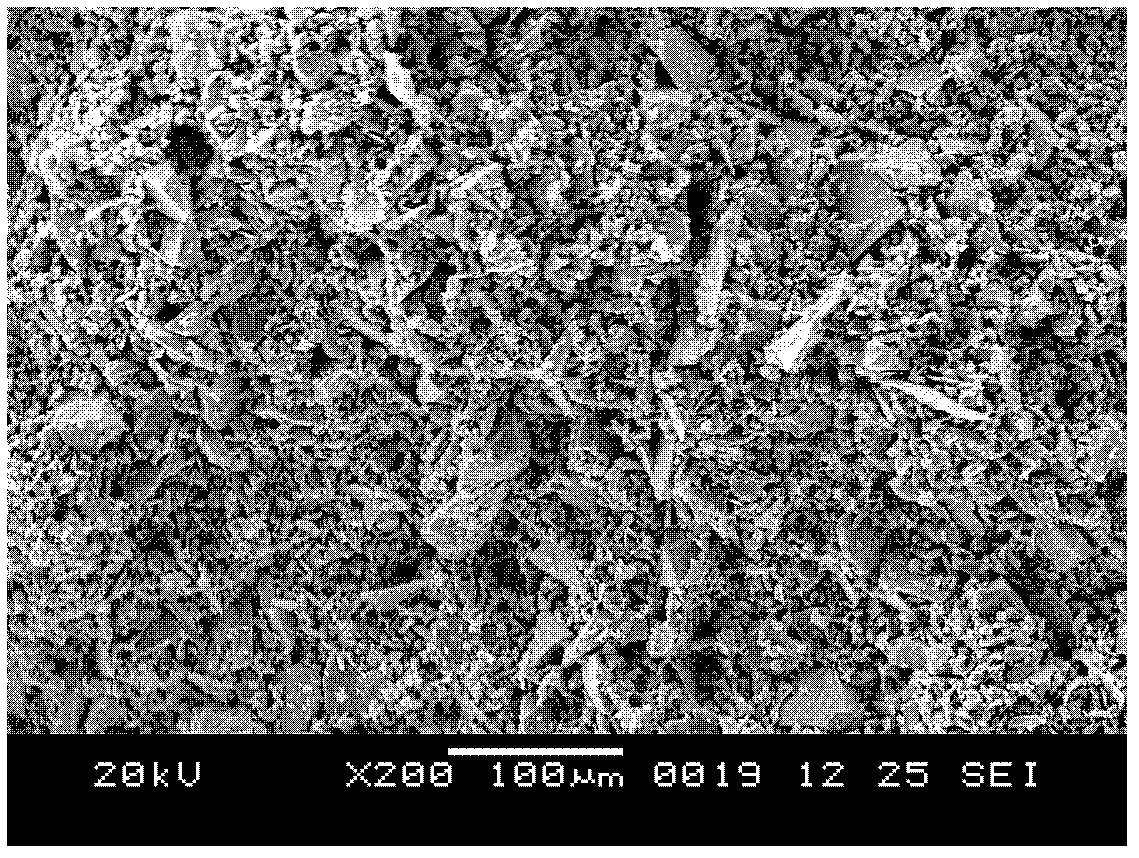

[0035] 2) Add 100 parts of 10 μm fine silicon carbide powder and 5 parts of polycarbosilane to the xylene solution, then ball mill and mix for 3 hours to obtain a cloudy solution; then remove the solvent in the cloudy solution to obtain polycarbosilane-coated Silicon carbide powder, ground and passed through a 100-mesh sieve; figure 2 middle right part and image 3 middle left part;

[0036] 3) A...

Embodiment 3

[0041] A method for preparing a pore-gradient silicon carbide porous ceramic, calculated with the total mass of added silicon carbide powder as 100 parts, the specific steps are:

[0042] 1) Add 20 parts of 10 μm fine silicon carbide powder, 80 parts of coarse silicon carbide powder and 5 parts of polycarbosilane into the xylene solution, then ball mill and mix for 3 hours to obtain a cloudy solution; then remove the solvent in the cloudy solution, Obtain silicon carbide powder coated with polycarbosilane, grind and pass through a 100-mesh sieve;

[0043] 2) Add 100 parts of 10 μm fine silicon carbide powder and 5 parts of polycarbosilane to the xylene solution, then ball mill and mix for 3 hours to obtain a cloudy solution; then remove the solvent in the cloudy solution to obtain polycarbosilane-coated Silicon carbide powder, ground and passed through a 100-mesh sieve;

[0044] 3) Add 100 parts of 10 μm fine silicon carbide powder, 5 parts of carbon powder and 5 parts of polyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com