Semi-automatic double-head riding welding machine

A semi-automatic, welding machine technology, applied in the direction of welding rod characteristics, welding equipment, arc welding equipment, etc., can solve the problems of welding trolleys with many constraints, unable to meet application needs, difficult to use and maintain, etc., to achieve easy to learn maintenance costs and reduce technology Improved cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

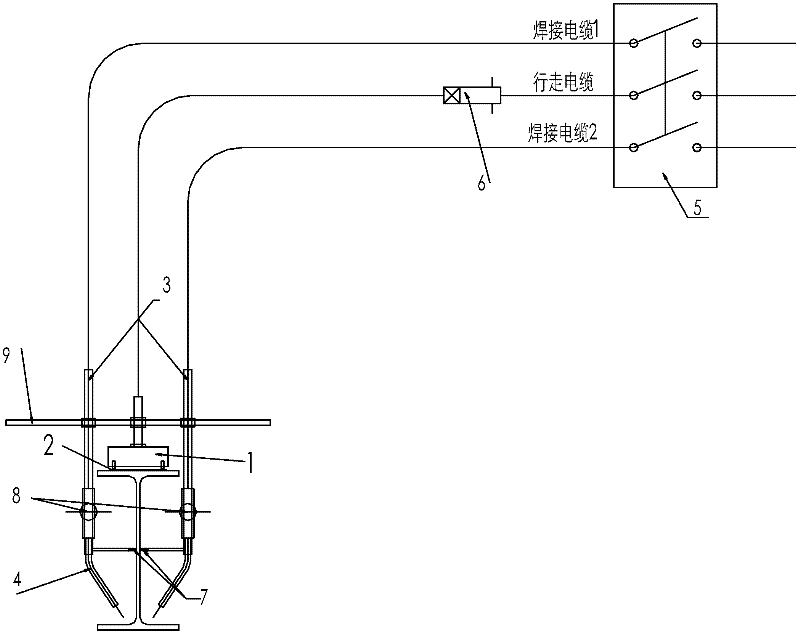

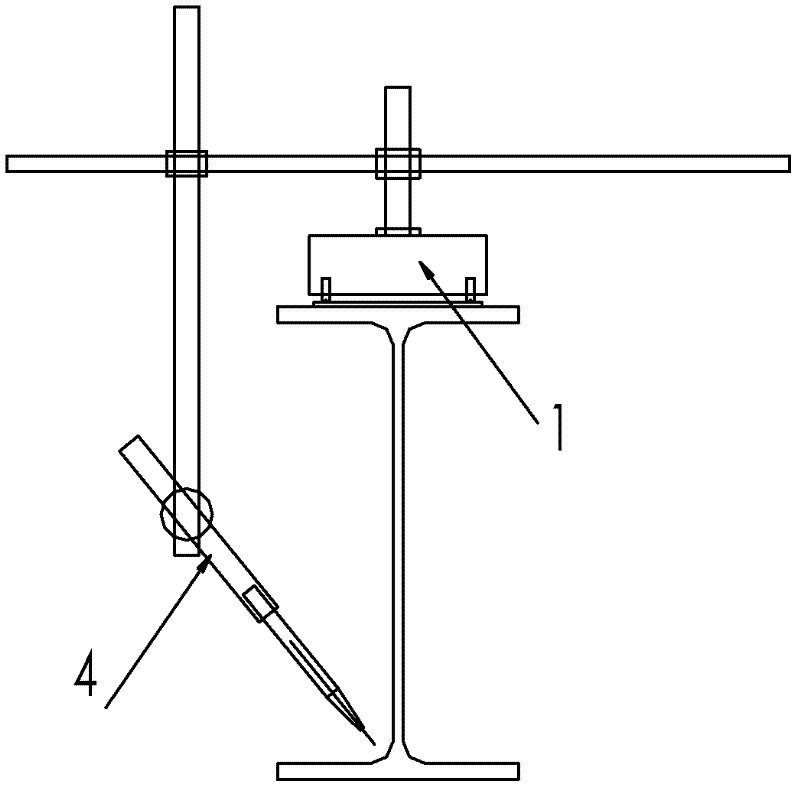

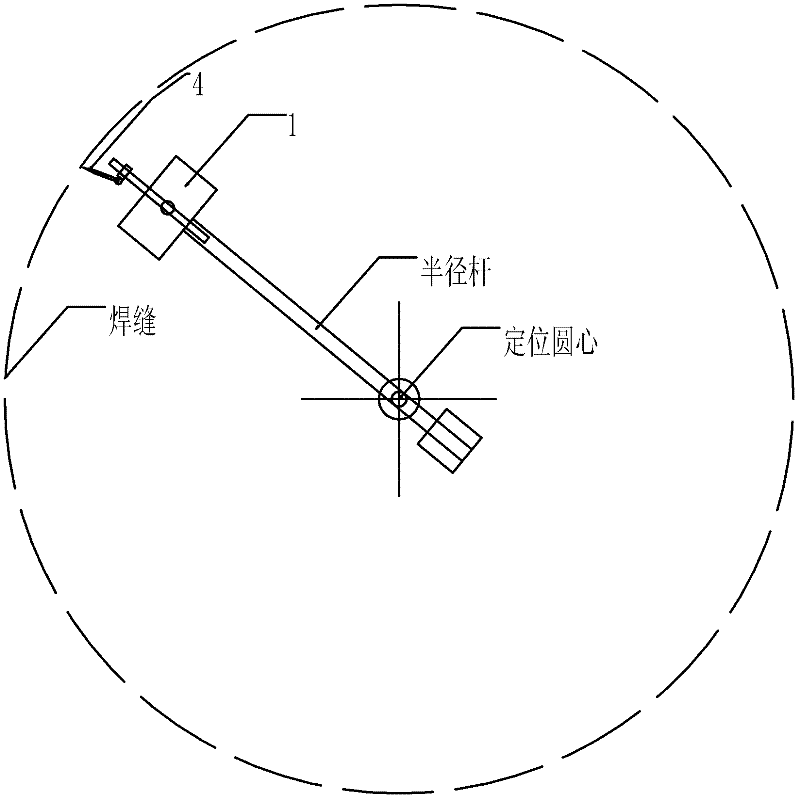

[0025] figure 1 Shown is a schematic structural diagram of a preferred semi-automatic double-head riding welding machine, which mainly includes a switch controller, a connecting cable, and a welding torch body; in the welding torch body, a fixed support is set at the center point of the welding trolley 1, and a horizontal distance is set on the fixed support Two-way adjustable horizontal welding arm 9, the two ends of the horizontal welding arm 9 are respectively provided with a vertical welding arm 3 with adjustable vertical height, and the lower end of the vertical welding arm 3 is connected to the welding gun head 4 through the gun head angle adjustment device 8; The switch controller is connected with the main body of the welding torch through a connecting cable. In this way, the horizontal distance of the welding torch head, the height and travel of the torch head, and the angle of the torch head can be adjusted arbitrarily, that is, it can be adjusted arbitrarily in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com