Oil seal structure used in high speed motor

A technology of high-speed motors and oil seals, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as easy leakage and reduce the service life of motors, and achieve the effect of improving sealing performance, simple structure, and weakening the ability of leakage transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

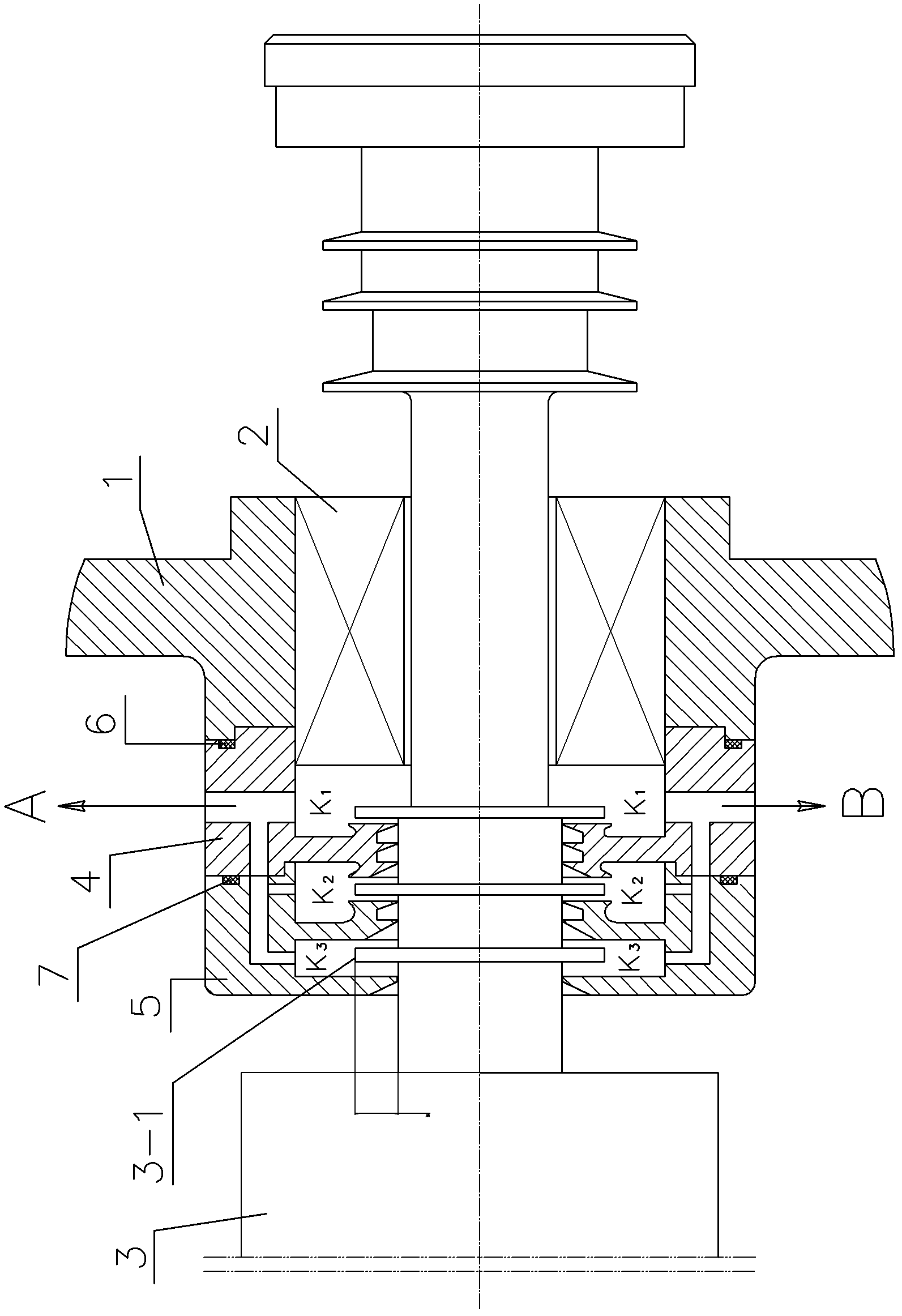

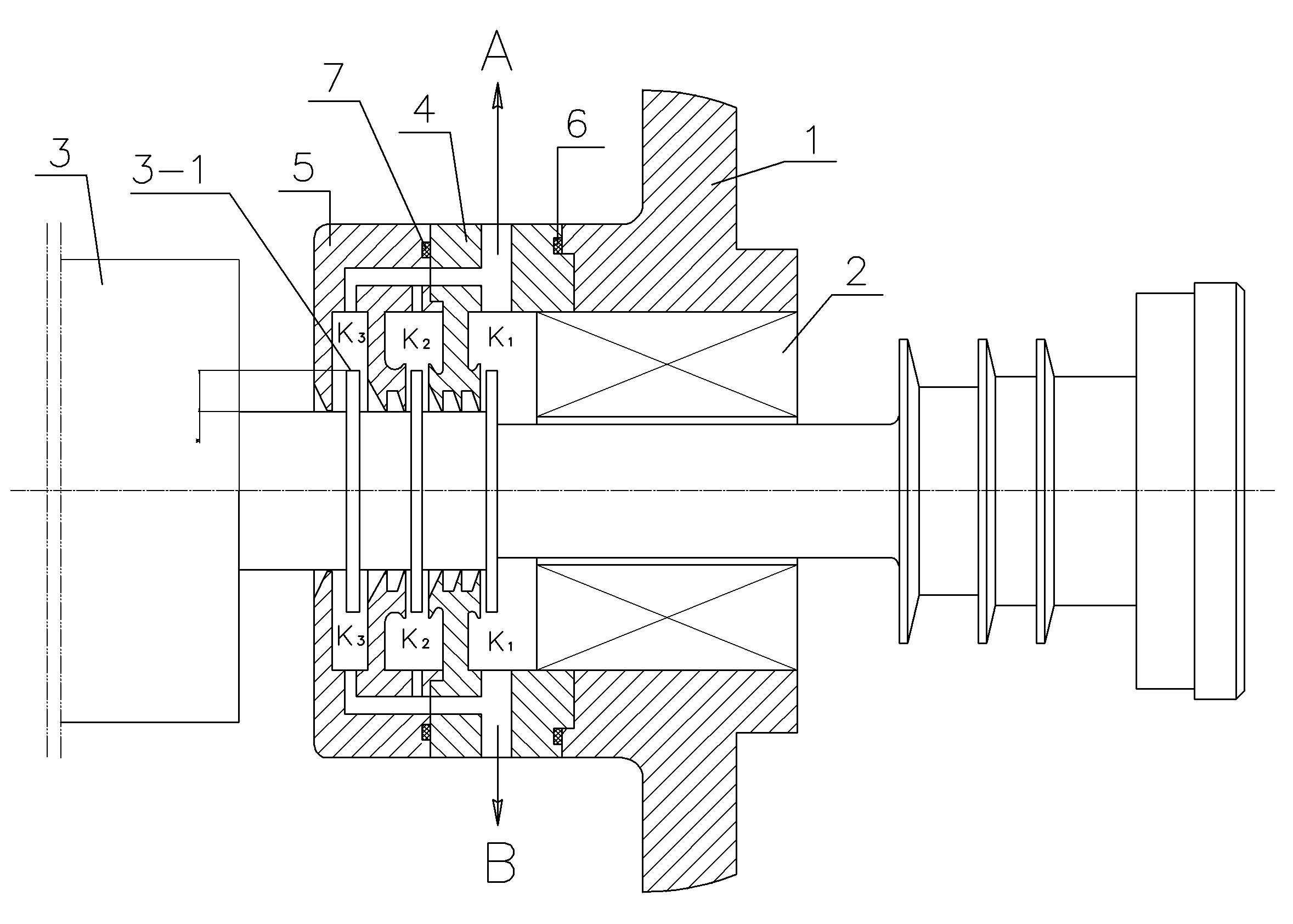

[0011] Below the present invention will be further described in conjunction with accompanying drawing:

[0012] Such as figure 1 As shown: the present invention includes a casing 1, a bearing 2, a rotor 3, a first oil seal 4, a second oil seal 5, a first O-ring 6, a second O-ring 7, and the like.

[0013] The rotor 3 is installed on the central axis of the bearing hole of the casing 1 by means of the bearing 2, and the first O-ring 6, the first oil seal 4, the first O-ring 6, the first oil seal 4, and the Two O-rings 7, the second oil seal 5; the first oil seal 4 and the second oil seal 5 are provided with several serrations, and the serrations and the rotor 3 form a labyrinth seal structure; the rotor 3 is provided with three The convex ring 3-1 divides the sawtooth into three subsections to form a three-level labyrinth structure and constitutes three first-level inter-space K1, second-level inter-space K2, and third-level inter-space K3; the first inter-level space K1 , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com