Film with bulge for computer keyboard or flexible printed circuit and bulge forming process thereof

A flexible circuit and molding process technology, applied in the direction of circuits, electrical components, electrical switches, etc., can solve the problems of difficult control of precision, high material consumption, and high mold cost, so as to reduce the production defect rate, reduce production costs, and shorten production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

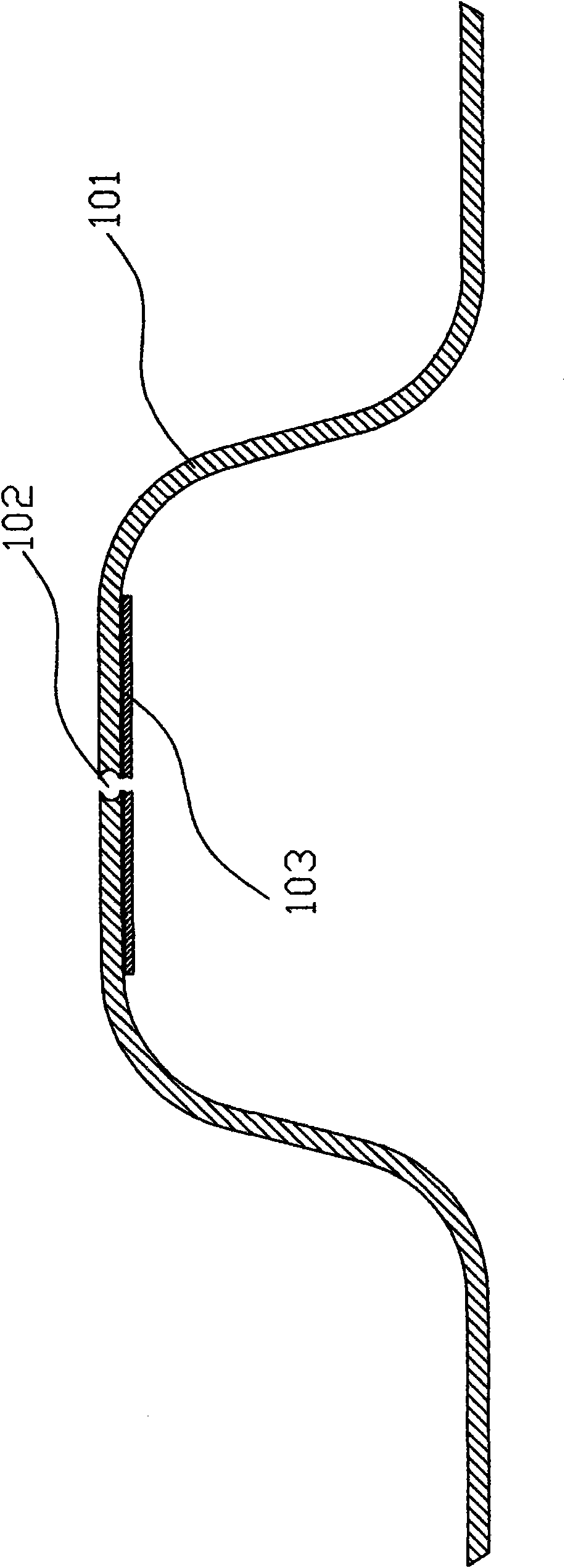

[0019] like figure 1 In the shown embodiment, a film or flexible circuit for a computer keyboard with protrusions has a light-transmitting hole 102 on the top of the protrusion 101, and the light is directed through the light-transmitting hole 102 and directly shines on the keyboard keycap. In order to replace the traditional sticking of lampshades, foam and other materials to achieve light gathering, light shielding, and stable light range, it also beautifies the lighting effect of the keyboard and enhances the light texture. The material 103 is used to prevent light from penetrating in a large area and affect the light-gathering effect, light intensity and appearance performance of keyboard lighting.

[0020] A kind of film or flexible circuit self-protrusion forming process for computer keyboard, comprising the following steps:

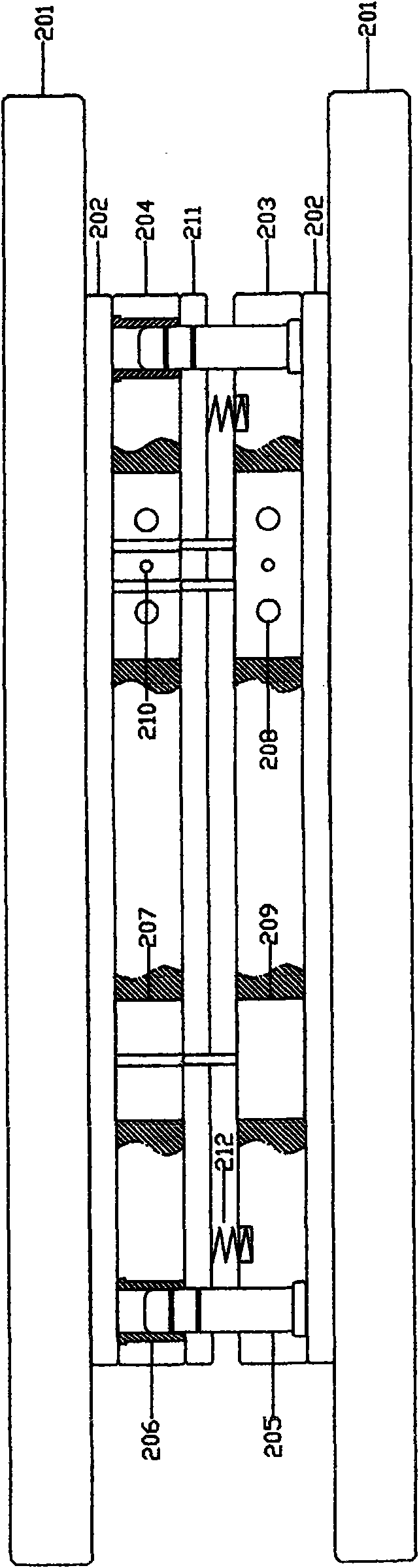

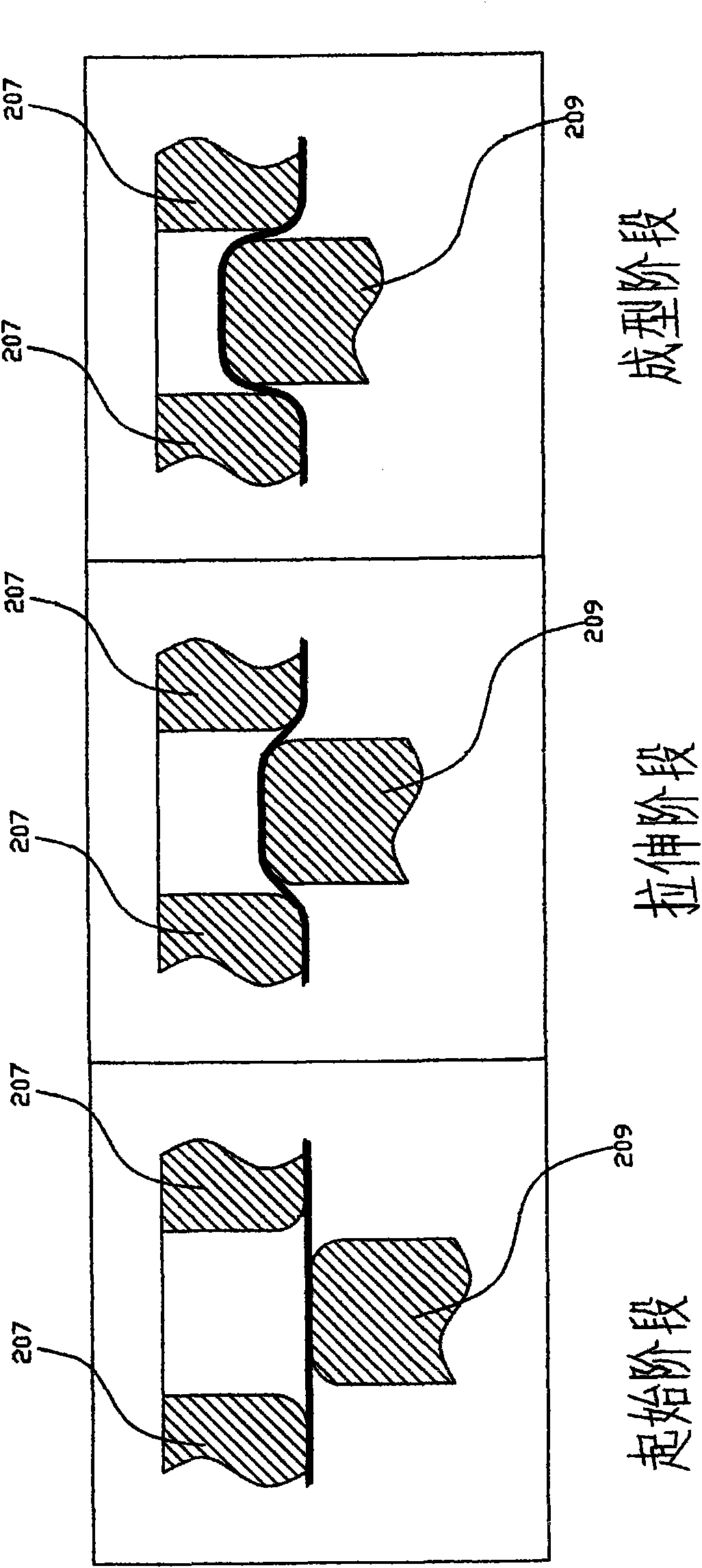

[0021] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com