Full-automatic double-reel combined winding machine

A combined, fully automatic technology, applied in coil manufacturing and other directions, can solve the problems of inability to process, poor stability, and uneven arrangement of automatic winding machines, and achieves increased effective clamping contact surface, easy control and operation , The effect of neat and beautiful wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The invention will be further described below in conjunction with the description of the accompanying drawings and specific embodiments:

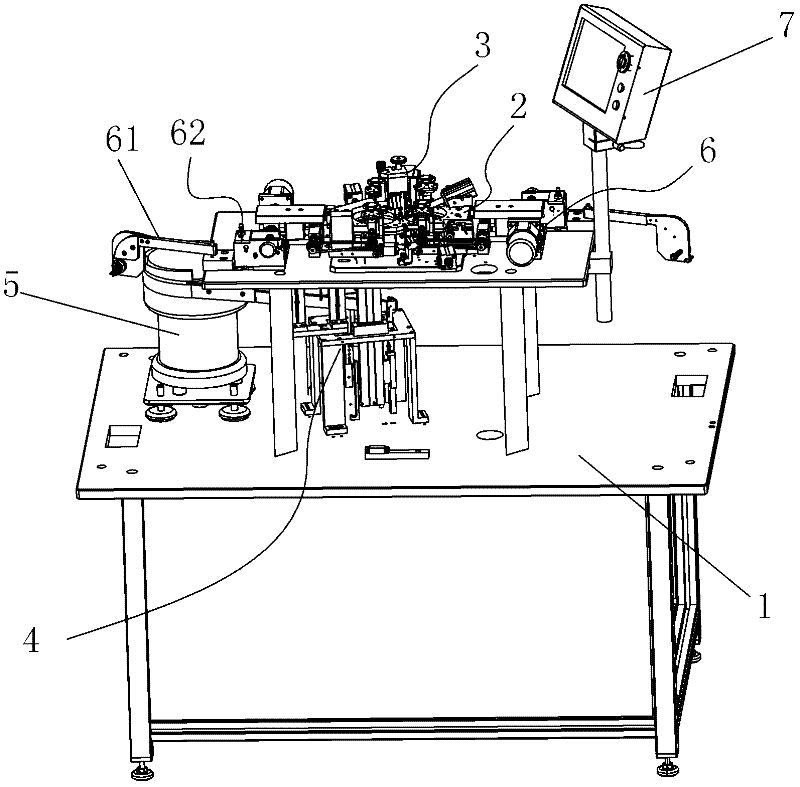

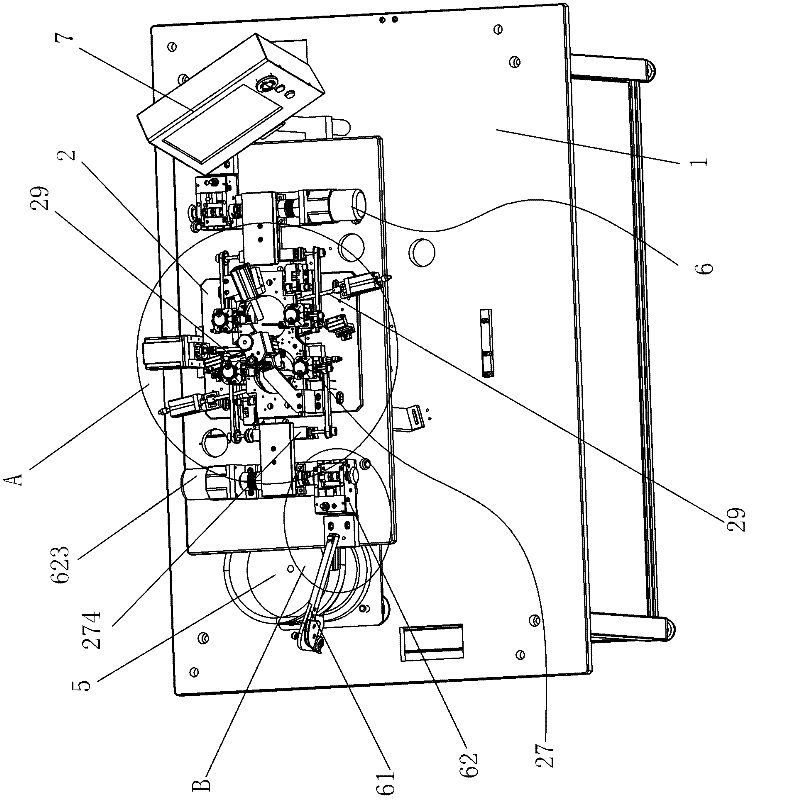

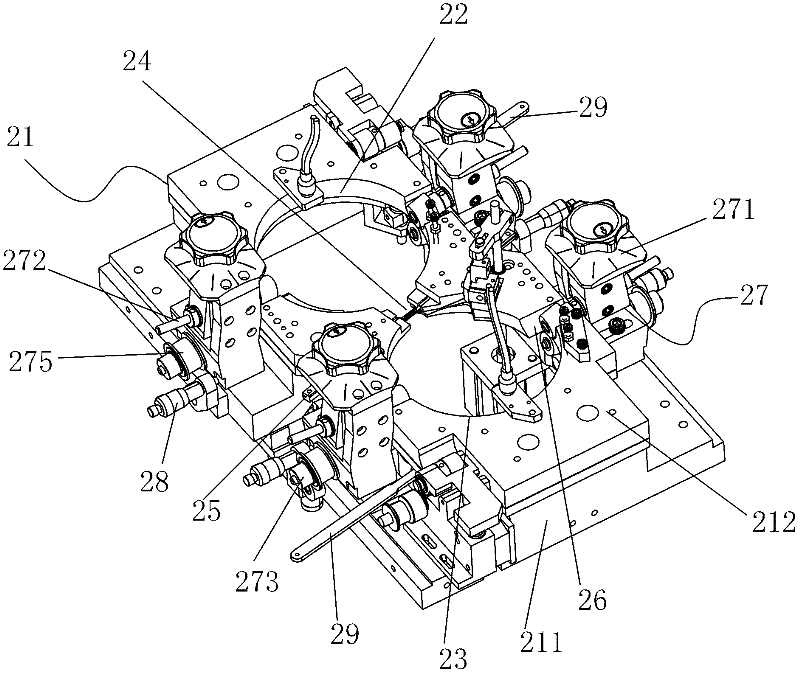

[0058] Such as Figures 1 to 10 The fully automatic double-disc combined winding machine shown includes a base 1, on which a double-disc combined winding reel 2 is arranged, and in the middle of the double-disc combined winding reel 2 A magnetic ring clamping device 3 is provided at the position where the magnetic ring is placed, and a vertical feeding mechanism that can feed the magnetic ring 8 into the magnetic ring clamping device 3 is provided below the double-disc combined winding reel 2 4. The vertical feeding mechanism 4 is connected with the vibrating feeder 5 arranged on the machine base 1, and the two ends of the double-disc combined winding reel 2 are respectively connected to feed the enameled wire into the double The wire feeding mechanism 6 of the reel-combined reel 2 is provided with a controller 7 on the base 1 to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com