Permanent magnet low-frequency multidegree of freedom vibration isolation mechanism based on negative stiffness principle

A technology with degrees of freedom and negative stiffness, used in magnetic springs, mechanical equipment, non-rotational vibration suppression, etc., can solve problems such as small bearing capacity, and achieve the effects of easy processing, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

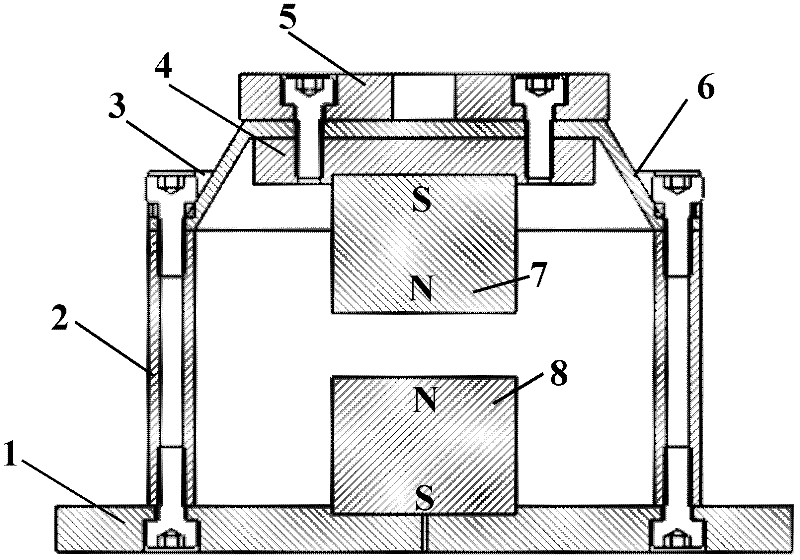

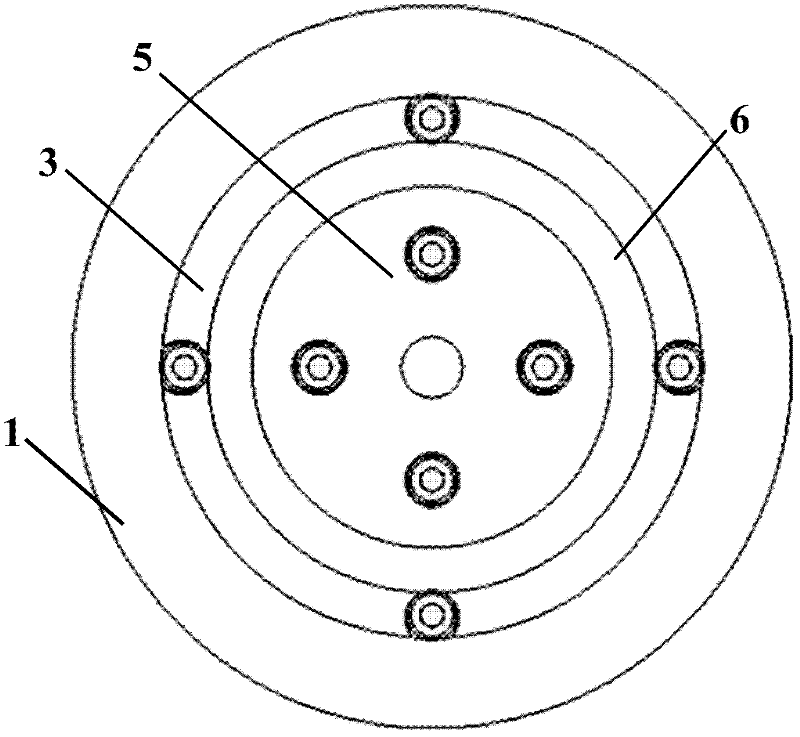

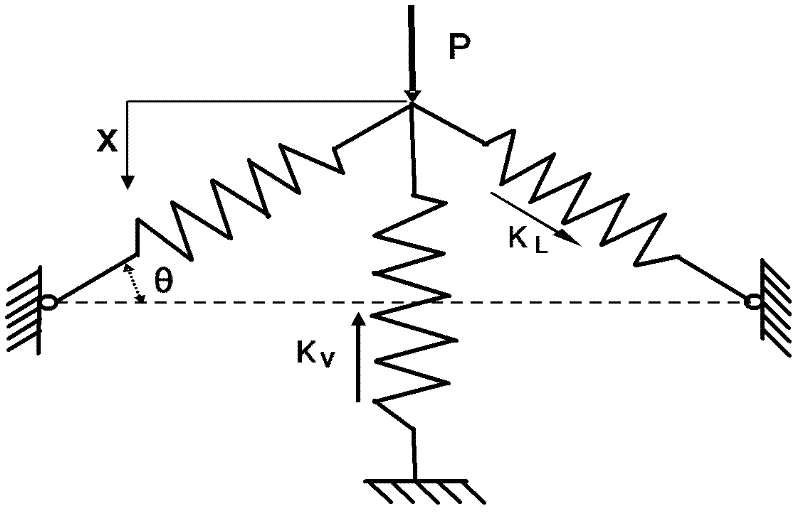

[0019] figure 1 , figure 2 A schematic structural diagram of an embodiment of a permanent magnet low-frequency three-degree-of-freedom vibration isolation mechanism based on the principle of negative stiffness provided by the present invention. The low-frequency three-degree-of-freedom vibration isolation mechanism includes a lower permanent magnet 8, an upper permanent magnet 7, a rubber sheet 6, a lower permanent magnet fixing plate 1, a rubber fixing seat 2, an upper permanent magnet fixing plate 4, a rubber pressing block 5 and a rubber sheet outer Edge fixing pressure ring 3; the upper permanent magnet 7 and the lower permanent magnet 8 are magnetized in the vertical direction, and the same poles are opposite, and the upper permanent magnet and the lower permanent magnet adopt cylindrical or rectangular permanent magnets. The rubber sheet adopts general industrial rubber or natural rubber, and the outer edge of the rubber sheet 6 is fixed on the rubber fixing seat 2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com