Piston guiding element, particularly piston guiding element for cylinder piston pump

A technology for hydraulic piston pumps and guiding components, which is applied in the direction of pump components, pumps, multi-cylinder pumps, etc., which can solve problems such as leakage and damage to sealing components, and achieve the effects of cost reduction, excellent wear protection, and ensuring piston guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

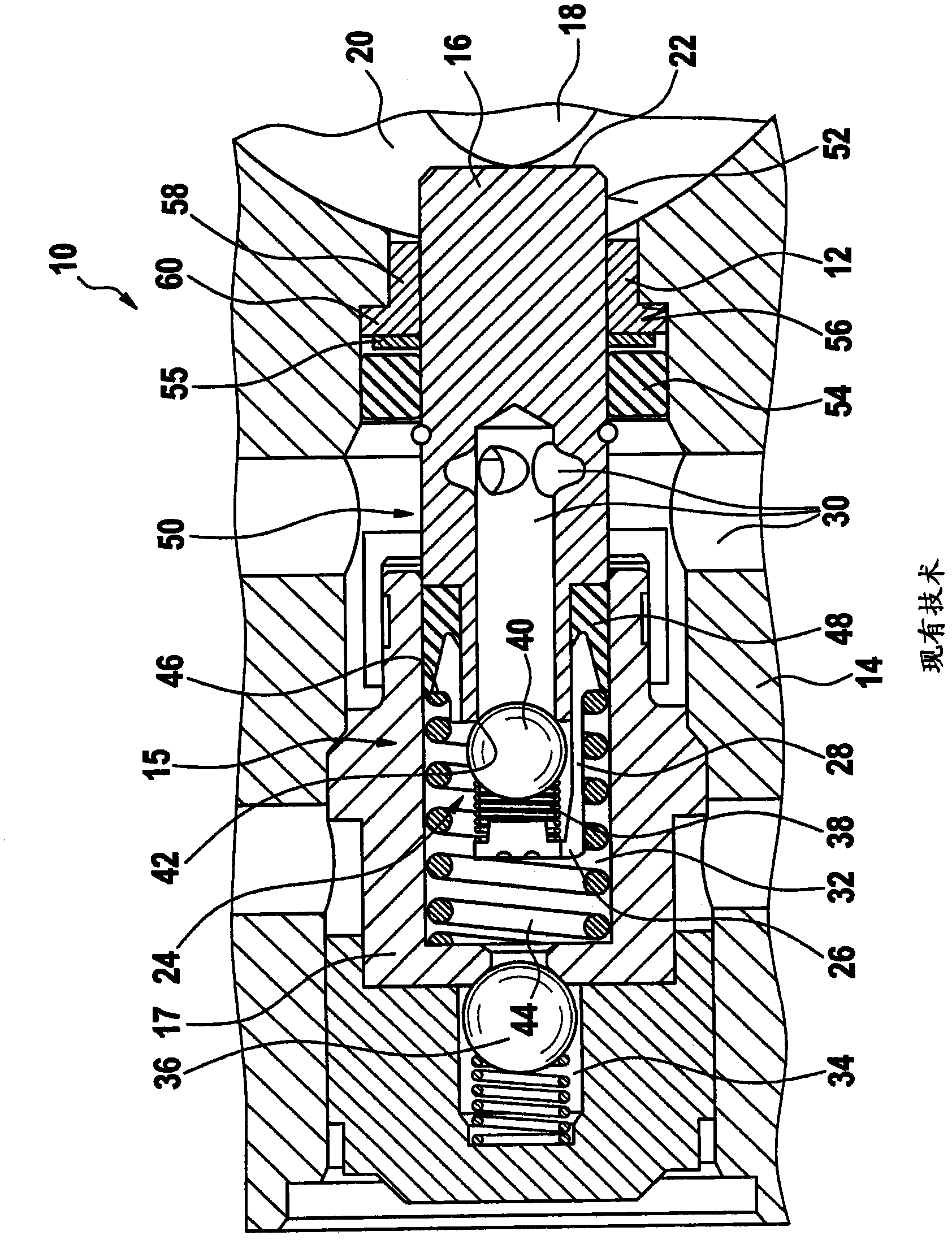

[0056] figure 1 A hydraulic piston pump 10 is shown with a low-pressure side guide ring 12 as a piston guide element according to the prior art.

[0057] The piston pump 10 comprises a pump housing 14 in which a cylinder-piston unit 15 is accommodated. In this cylinder-piston unit 15 there is a piston 16 which is movable in a cylinder 17 along a longitudinal axis. During operation of the piston pump 10 , the piston 16 is driven by a rotating eccentric 18 which is arranged in an eccentric chamber 20 . The eccentric 18 rests with its outer circumference against the end face 22 of the piston 16 and moves the piston 16 in or out of the cylinder 17 .

[0058] A suction valve 24 is assigned to the piston 16 . The intake valve 24 is arranged in a valve housing 26 which is clamped on a holder 28 . The suction valve 24 is designed to suck fluid into the pressure area 32 inside the cylinder 17 by means of the reciprocating movement of the piston 16 via the suction device 30 and to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com