Self-balancing iron driller

An automatic balancing and iron driller technology, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of large hinge points of components, large component design, unfavorable promotion and application, etc., to reduce force and save energy. Manufacturing cost, effect for compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

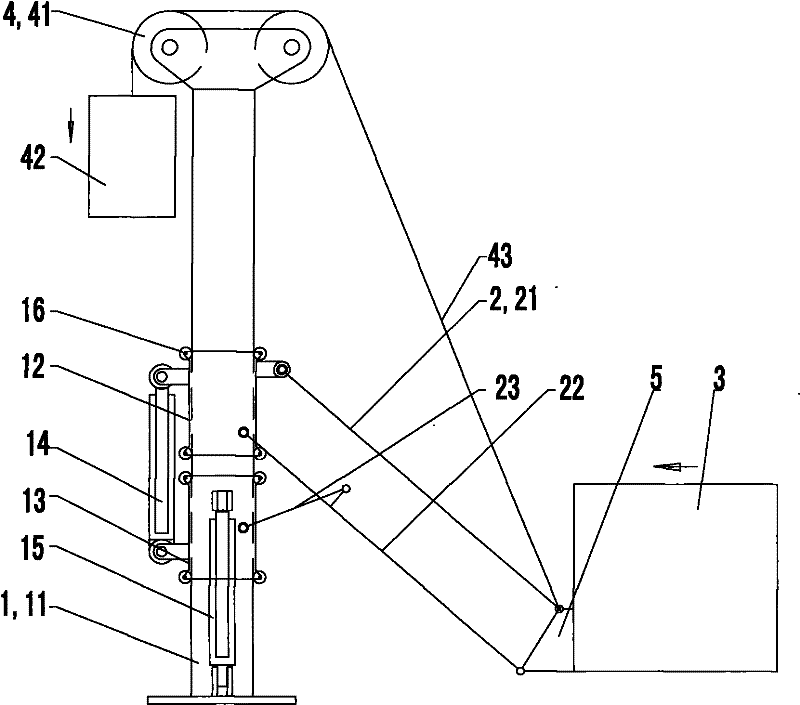

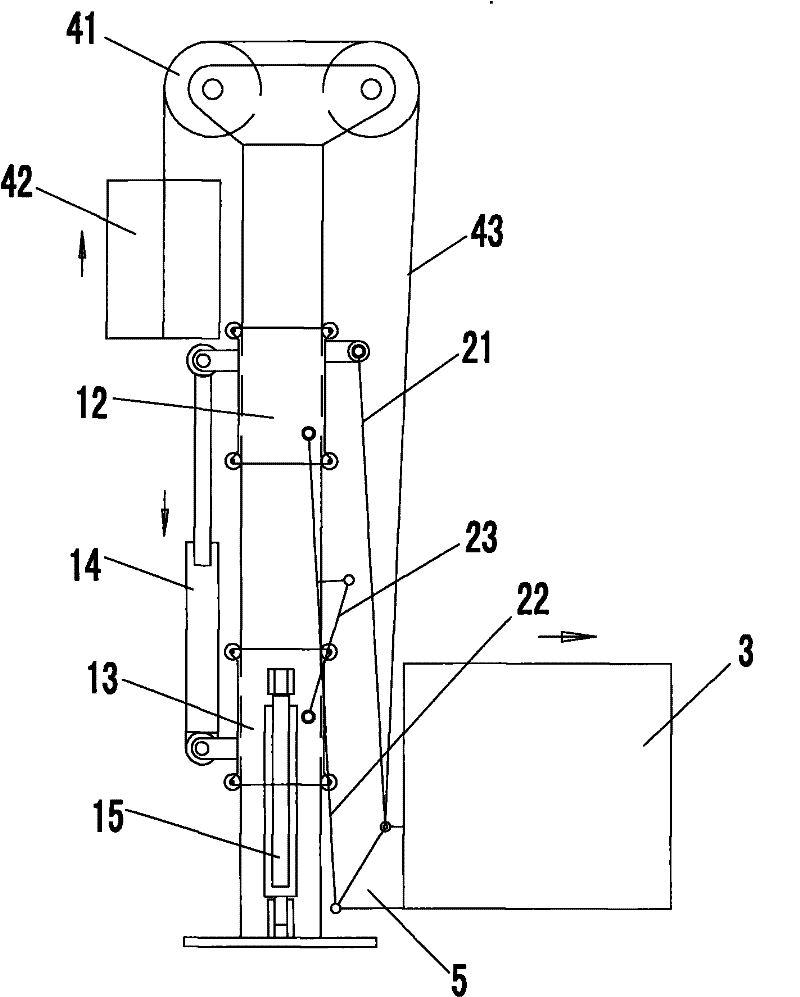

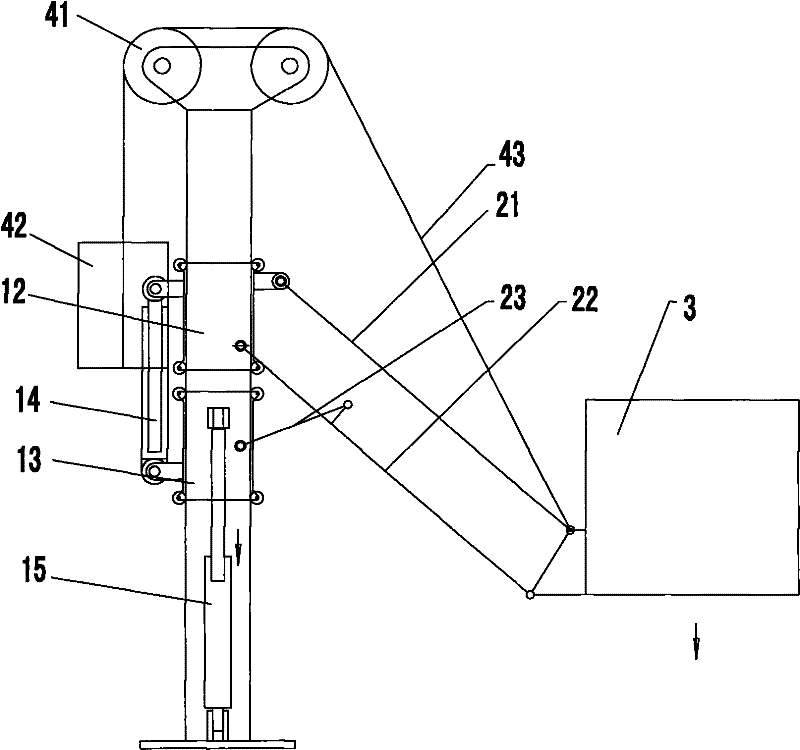

[0018] See figure 1 , The automatic balancing iron drill of the present invention includes a lifting mechanism 1, a telescopic swing mechanism 2, a working tool 3, and a balancing mechanism 4. One side of the working tool 3 is connected with a hinge joint block 5, and the telescopic swing mechanism 2 is movably connected to Between the lifting mechanism 1 and the hinge joint block 5.

[0019] The balance mechanism 4 in the present invention includes a balance wheel 41, a balance weight 42, and a balance rope 43. The balance wheel 41 is arranged at the top of the lifting mechanism 1, the balance weight 42 is suspended on one side of the lifting mechanism 1, and one end of the balance rope 43 is connected On the hinged coupling block 5 or connected to the working tool 3, the other end bypasses the balance wheel 41 and is connected to the balance block 42.

[0020] There are preferably two balance wheels 41 in the present invention. The two balance wheels are installed in parallel on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com