Hollow glass with sun-shading curtain inside

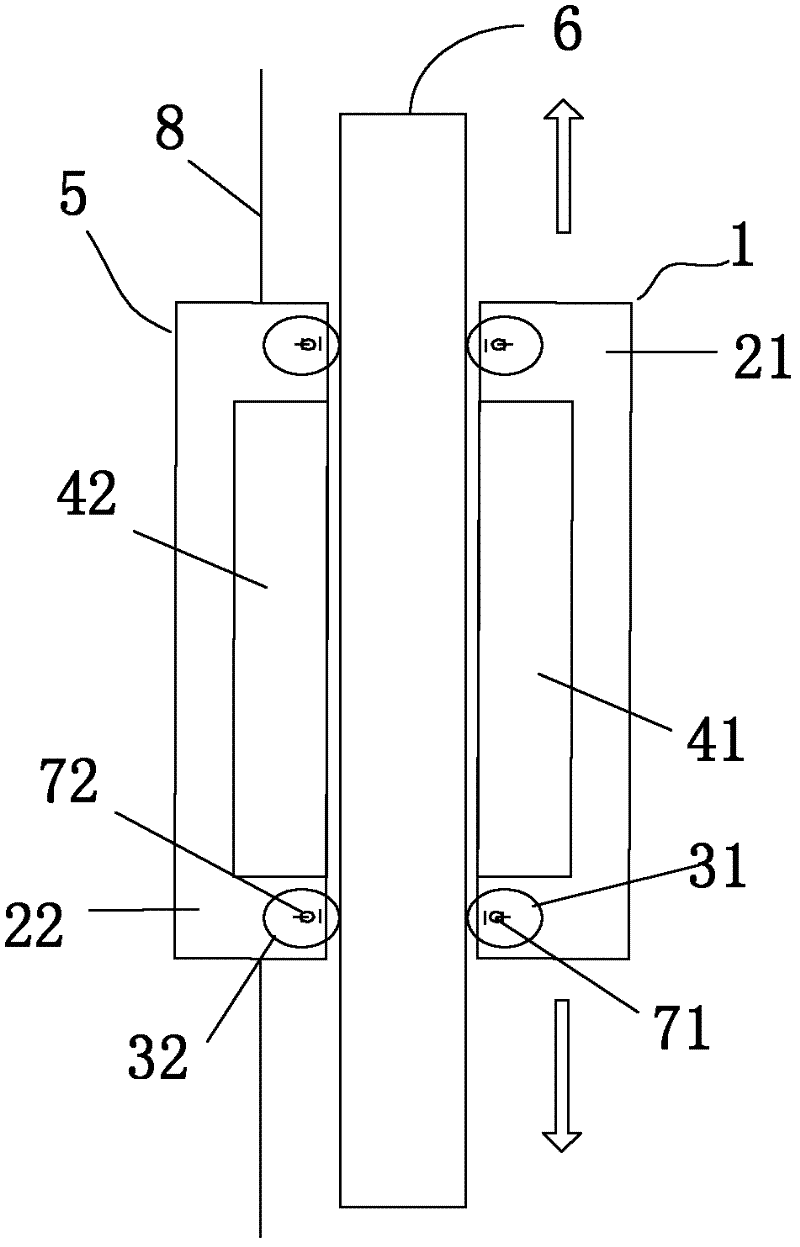

A sunshade and glass technology, applied in parallel glass structures, shading screens, etc., can solve the problems of unsatisfactory limit effect, large operation force, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

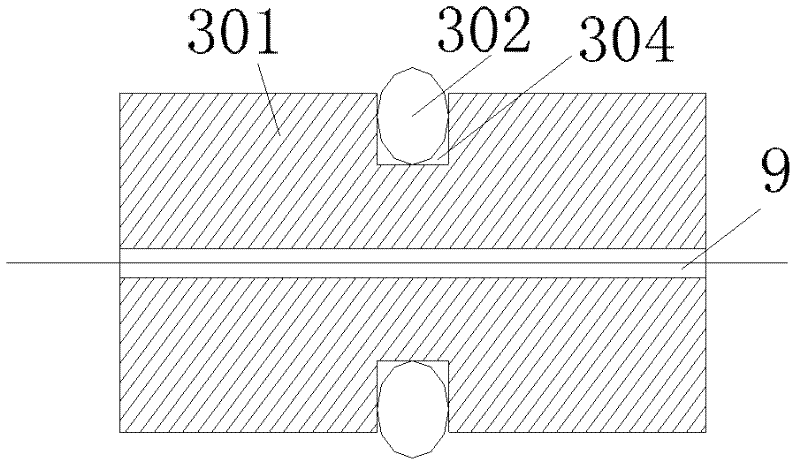

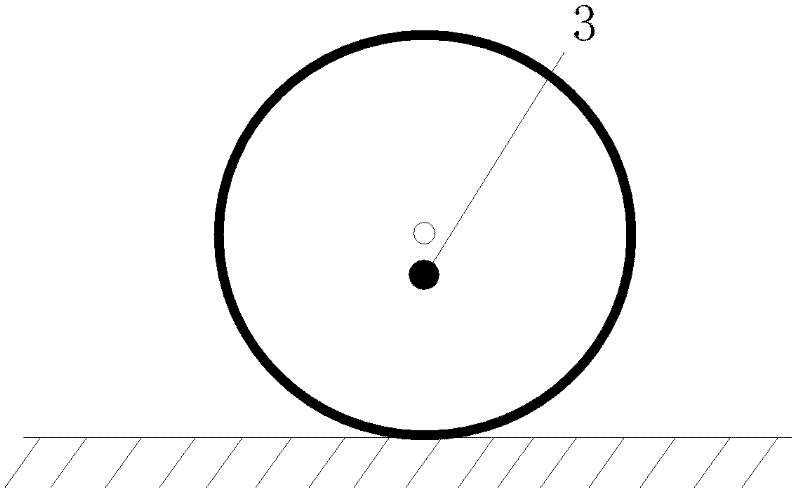

[0027] Embodiment one: if image 3 As shown, the section of the roller along the vertical axis 9 is circular, and the axis 9 deviates from the center of the circle. The resistance position refers to the position closest to the axis 9 on the wheel surface. There is only one position, and the flexible material 302 surrounds the entire wheel surface . The roller only needs to ensure that the axis 9 deviates from the axis 9, and the processing is simple and the cost is low.

Embodiment 2

[0028] Embodiment two: if Figure 4 As shown, the cross-section of the roller along the vertical direction of the axis 9 is elliptical, and the resistance position refers to the position closest to the axis 9 on the wheel surface. Due to the symmetrical characteristics of the ellipse, there are two positions, and the flexible material 302 surrounds the entire Wheel surface. The roller utilizes the natural properties of the ellipse to realize two resistance positions with high control precision.

Embodiment 3

[0029]Embodiment three: as Figure 5 As shown, the cross-section of the roller along the vertical direction of the axis 9 is a polygon, and the resistance position refers to each plane of the roller. The flexible material 302 can surround the entire wheel surface to enhance the friction of the entire wheel surface; it can also be distributed on each surface of the roller. Flat sides for enhanced friction at resistance locations. The number of resistance positions of the roller is the same as the number of sides of the polygon, so multiple resistance positions can be realized, and the control accuracy is higher. In addition, the resistance position is a plane, and the friction force with the contact surface is large, so the limit effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com