Reducing and sudden expansion type inner energy dissipator

A technology of energy dissipation and sudden expansion, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of increased project cost, large amount of construction work, small operating flow, etc., and achieves easy design and construction, anti-cavitation performance Good, the effect of improving the energy dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

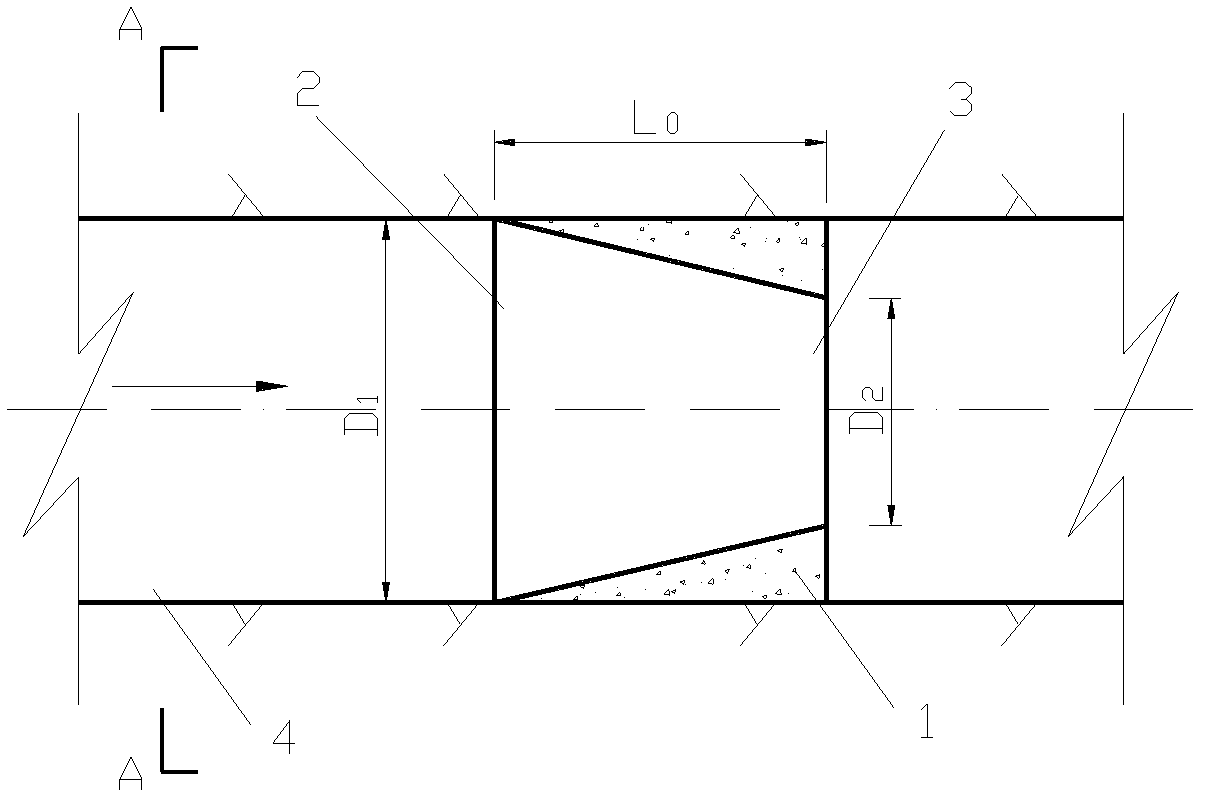

[0024] In this embodiment, the structure of the tapered and suddenly expanded internal flow energy dissipator is as follows figure 2 , image 3 As shown, it consists of a base body 1 and flow holes provided in the base body, the flow hole is a constricted truncated conical hole with the inlet 2 larger than the outlet 3 .

[0025] The tapered and suddenly expanded internal flow energy dissipation device described in this embodiment is used for the hole diameter D 1 = 20m spillway tunnel energy dissipation, the relevant dimensions are as follows: flow hole inlet diameter = spillway tunnel diameter D 1 =20m, outlet diameter of flow hole D 2 =0.415D 1 =8.3m, the length of the flow hole is the same as the length of the base, both are L 0 , the L 0 =0.5D 1 = 10m. The tapered-sudden-expanded internal flow energy dissipator described in this embodiment is made of conventional concrete.

Embodiment 2

[0027] In this embodiment, the structure of the tapered and suddenly expanded internal flow energy dissipator is as follows figure 2 , image 3 As shown, it consists of a base body 1 and flow holes provided in the base body, the flow hole is a constricted truncated conical hole with the inlet 2 larger than the outlet 3 .

[0028] The tapered and suddenly expanded internal flow energy dissipation device described in this embodiment is used for the hole diameter D 1 = 20m spillway tunnel energy dissipation, the relevant dimensions are as follows: flow hole inlet diameter = spillway tunnel diameter D 1 =20m, outlet diameter of flow hole D 2 =0.4D 1 =8.0m, the length of the flow hole is the same as the length of the base, both are L 0 , the L 0 =0.5D 1 = 10m. The tapered-sudden-expanded internal flow energy dissipator described in this embodiment is made of conventional concrete.

Embodiment 3

[0030] This embodiment is a flood discharge tunnel converted from a diversion tunnel of a large power station, and the diameter of the flood discharge tunnel is D 1 20m, maximum water head 200m, discharge flow 2600m 3 / s, a first-level tapered and suddenly expanded internal flow energy dissipator is arranged, such as Figure 5 shown.

[0031] The tapered and suddenly expanded internal flow energy dissipator 5 used in this embodiment is the tapered and suddenly expanded internal flow energy dissipator with the structure and size described in Embodiment 1. After the water flows through the energy dissipator, the head of the piezometric tube is reduced by 79m, that is, the energy dissipating head is 79m. In this embodiment, the energy dissipation requirements of the project can be met only by using one-stage tapered and suddenly expanded internal flow energy dissipator, and the inlet section of the energy dissipator has no cavitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com