Taking-out device of long monocrystalline silicon rods

A technology for taking out a device and a single crystal silicon rod, which is applied in the directions of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problem that the secondary chamber 104 and the furnace cover 102 cannot be rotated reliably synchronously, the work intensity is increased, and the time and effort is consuming. problems, to achieve the effect of improving safety, improving safety, and accurate centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

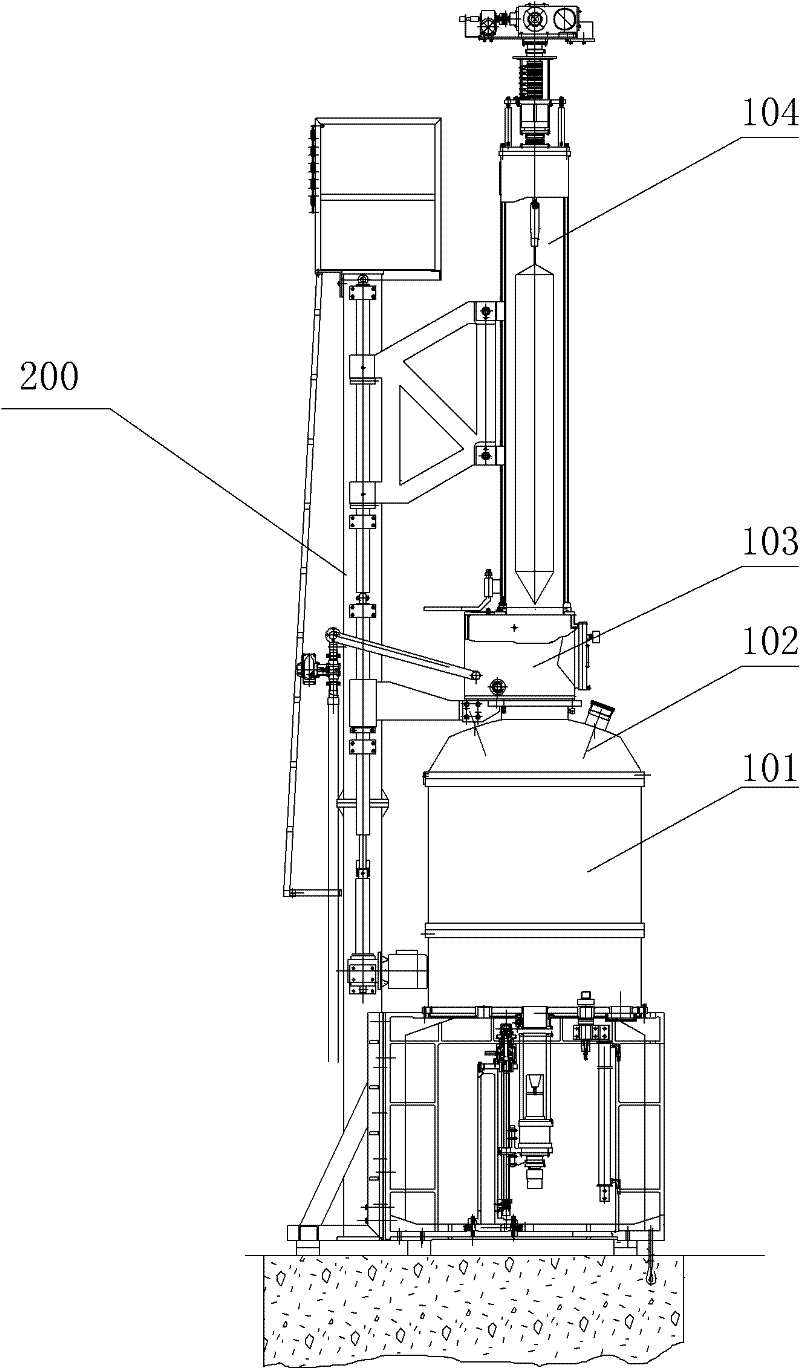

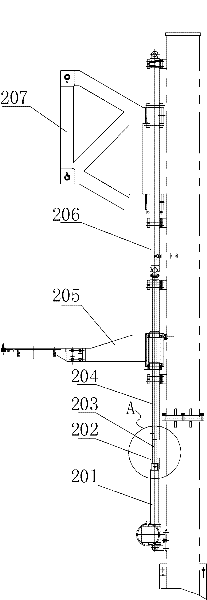

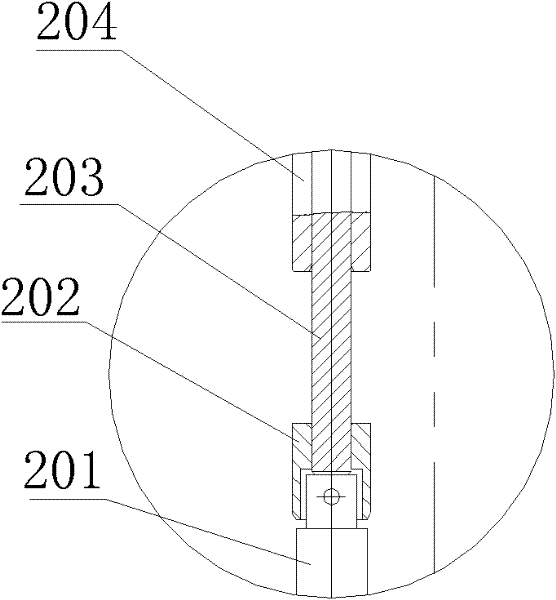

[0050] Please refer to Figure 5 , Figure 6 , which is a structural schematic diagram of Embodiment 1 of the device for taking out long monocrystalline silicon rods of the present invention and Figure 5 Schematic diagram of the enlarged structure in part B. As shown in the figure, the device for taking out long single crystal silicon rods proposed by the present invention is used in silicon single crystal furnaces, including electric push rods 1, electric push rod connecting blocks 2, jacking shafts 3, furnace Lid lifting shaft 4, furnace lid lifting connecting piece 5, auxiliary chamber lifting shaft 6 and auxiliary chamber lifting connecting piece 7, jacking shaft 3 runs through furnace lid lifting shaft 4 and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com