Halogen-free environment-friendly bonding agent and preparation method thereof

An adhesive and environmentally friendly technology, applied in the direction of adhesive types, non-polymer adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve problems such as environmental pollution and biological damage, and achieve durability Effects of good CAF, low water absorption, and low Z-CTE value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

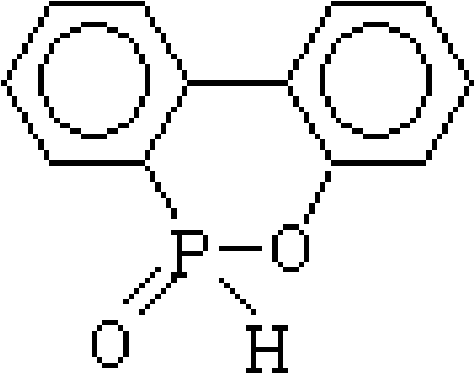

Problems solved by technology

Method used

Image

Examples

Embodiment 1

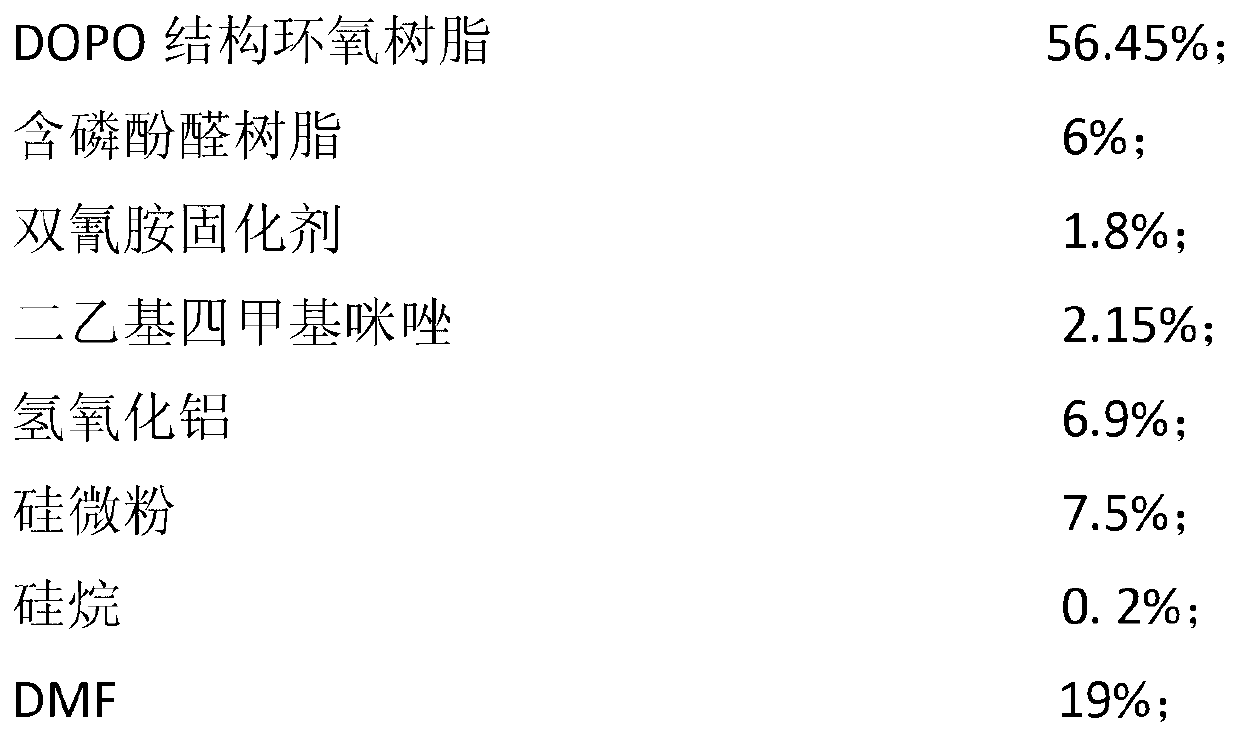

[0049] 1. Raw material ratio of halogen-free environmental protection adhesive

[0050] raw material

Formula ratio (mass ratio)

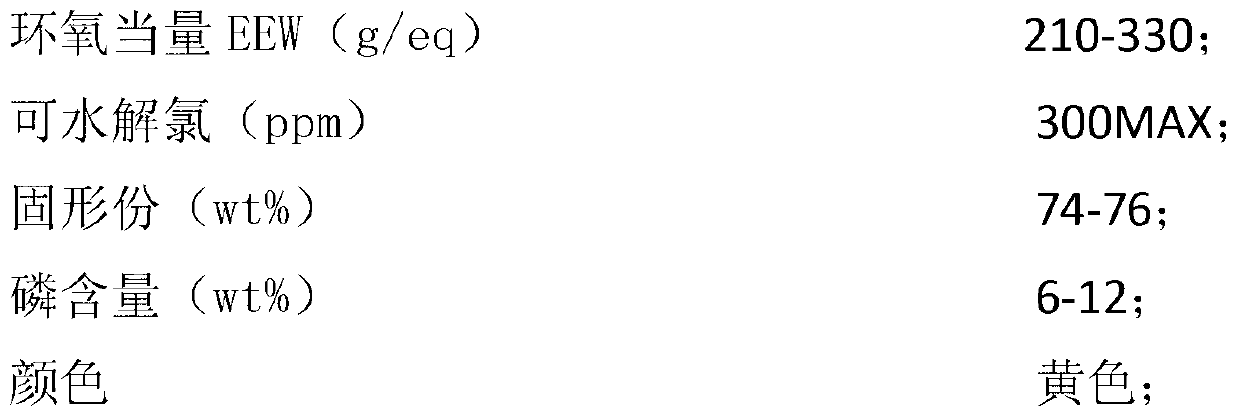

[0051] DOPO Structural Epoxy Resin

64.83

Phosphorus-containing phenolic resin

5

Dicyandiamide curing agent

2

Diethyltetramethylimidazole

0.15

Aluminum hydroxide (average particle size<8μm)

7.4

Silica powder (i.e. SiO 2 Powder, average particle size <8μm)

5.5

Silane

0.12

DMF

15

[0052] 2. Preparation process:

[0053] a>Add DMF, silane and dicyandiamide curing agent into the mixing tank according to the proportion, start the high-speed stirrer to stir, and the speed of the stirrer is 1700 rpm, then add aluminum hydroxide and silicon micropowder and stir for 2 hours, control the stirring tank The temperature is at 40°C;

[0054] b>Add phosphorus-containing phenolic resin and DOPO structure epoxy resin within 50 min...

Embodiment 2

[0065] 1. Raw material ratio of halogen-free environmental protection adhesive

[0066] raw material

Formula ratio (mass ratio)

DOPO Structural Epoxy Resin

69.37

Phosphorus-containing phenolic resin

4

Dicyandiamide curing agent

2

Diethyltetramethylimidazole

1.15

Aluminum hydroxide (average particle size<8μm)

5.5

Silica powder (i.e. SiO 2 Powder, average particle size <8μm)

4.8

Silane

0.18

DMF

13

[0067] 2. Preparation process:

[0068] a>Add DMF, silane and dicyandiamide curing agent into the mixing tank according to the proportion, turn on the high-speed stirrer to stir, the stirrer speed is 1700 rpm, then add aluminum hydroxide, silicon micropowder and stir for 1-3 hours, control the stirring The temperature in the tank is 40°C;

[0069] b>Add phosphorus-containing phenolic resin and DOPO structure epoxy resin within 50 minutes after step a> is com...

Embodiment 3

[0080] 1. Raw material ratio of halogen-free environmental protection adhesive

[0081] raw material

Formula ratio (mass ratio)

DOPO Structural Epoxy Resin

56.45

Phosphorus-containing phenolic resin

6

Dicyandiamide curing agent

1.8

Diethyltetramethylimidazole

2.15

Aluminum hydroxide (average particle size<8μm)

6.9

Silica powder (i.e. SiO 2 Powder, average particle size <8μm)

7.5

Silane

0.20

DMF

19

[0082] 2. Preparation process:

[0083] a>Add DMF, silane and dicyandiamide curing agent into the mixing tank according to the proportion, start the high-speed stirrer to stir, and the speed of the stirrer is 1700 rpm, then add aluminum hydroxide and silicon micropowder and stir for 2 hours, control the stirring tank The temperature is at 40°C;

[0084] b>Add phosphorus-containing phenolic resin and DOPO structure epoxy resin within 50 minutes after step a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com