Integral keel and skin composite self-propelled equipment capsule structure

A composite, self-propelled technology, applied in the direction of the fuselage bulkhead, etc., can solve the problem of large skin strain, and achieve the effects of reducing the demanding process path, simple calibration, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] see figure 1 , the self-propelled equipment cabin structure of integral keel and skin composite type in the present embodiment is the cabin structure of aircraft, and it comprises keel 1 and skin 2, and the outer wall of keel 1 is provided with spiral groove 11, simultaneously, A threaded groove 1a is also provided on the longitudinal rib on the keel 1, and the inner wall of the skin 2 is provided with a thread 21 that cooperates with the spiral groove 11 and a non-continuous threaded rib 2a that cooperates with the threaded groove 1a. 21 cooperates with the spiral groove 11 and the cooperation of the thread groove 1a and the thread rib 2a makes the keel and the skin detachably fixed together.

[0046] In other embodiments, it can also be set in this way: that is, a spiral groove is provided on the inner wall of the skin, and a screw thread is provided on the outer wall of the keel, so that a spiral connection can also be realized, and the keel and the skin are combined...

Embodiment 2

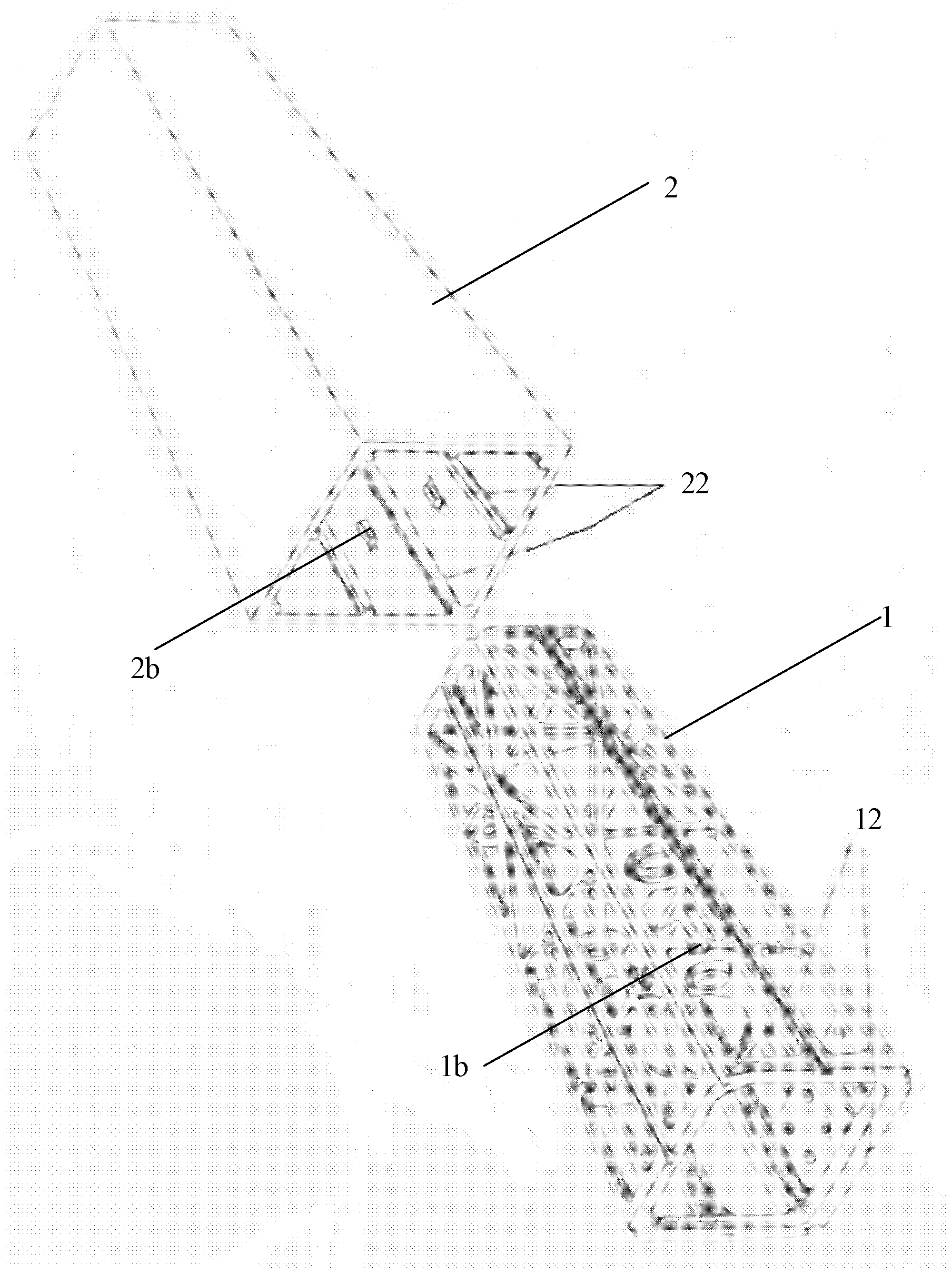

[0050] see figure 2 , this embodiment adopts the same spiral connection method as the first embodiment, the difference lies in the shape of the keel and the skin of the two, which will not be repeated here.

Embodiment 3

[0052] see image 3 , the self-propelled equipment cabin structure of integral keel and skin composite type in the present embodiment is the cabin structure of aircraft, and it comprises keel 1 and skin 2, and the outer wall of keel 1 is provided with slot 12, simultaneously, Slots 1b are also provided on the clapboard structure perpendicular to the course on the keel, and the inner wall of the skin 2 is provided with inserting ribs 22 matching with the slots 12 and incoherent inserting ribs matching with the slots 1b. Rib 2b, through the cooperation of inserting rib 22 and slot 12 and the cooperation of inserting rib 2b and slot 1b, the keel and skin are matched together.

[0053] In other embodiments, it can also be set in this way: that is, slots are set on the inner wall of the skin, and insert ribs are set on the outer wall of the keel, so that plug-in connection can also be realized, and the keel and the skin are combined together.

[0054] Wherein, the skin in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com