Compound multifunctional health-care mattess structure

A multi-functional and health-care technology, applied in mattresses, spring mattresses, stuffed cushions, etc., can solve problems such as insufficient air permeability, difficult foam layer to disperse, and user needs, so as to achieve good performance and reduce lumps , the effect of improving symptoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

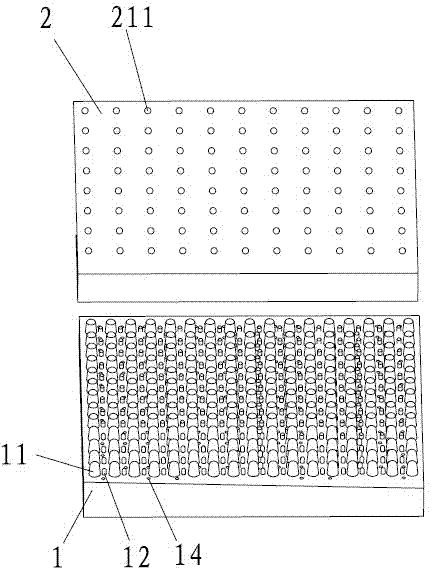

[0074] Embodiment 1: as figure 1 Shown, a kind of composite multifunctional health-care mattress structure, comprises the substrate 1 that runs through and is provided with ventilating hole 2 14, covers substrate 1 and is provided with the latex cotton layer 2 of magnetic strip, has ventilating hole 1 211 on the latex cotton layer 2 There are multiple rows of jacks on the latex cotton layer 2; the upper surface of the substrate 1 is provided with pressing columns 11 corresponding to the jacks one by one and plugged in; ; The thickness of the latex cotton layer is between 7cm and 15cm; the magnetic strip is not shown in the figure, and the jack is not shown in the figure.

Embodiment 2

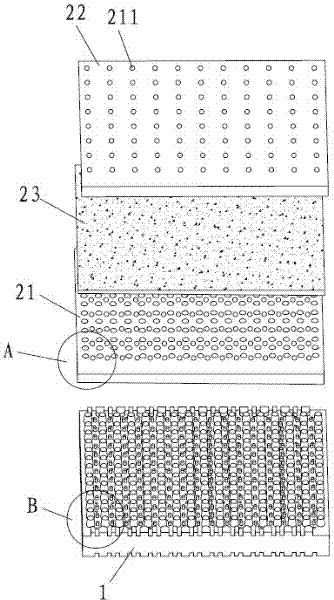

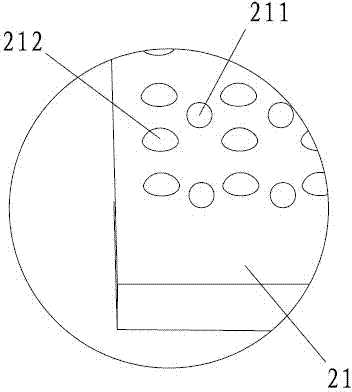

[0075] Embodiment 2: as Figures 2 to 5 Shown, a kind of composite multifunctional health-care mattress structure, comprises the base plate 1 that has air-vent 2 14, covers base plate 1 and is provided with the latex cotton layer of magnetic strip, the latex cotton layer is divided into from bottom to top and has breathable The lining layer 21 and the cushion layer 22 of the hole 211; the elastic polyester cotton layer 23 with a hole density of 90% is arranged between the lining layer 21 and the cushion layer 22; Holes 212; the upper surface of the substrate 1 is provided with a one-to-one correspondence with the socket 212 and is plugged in, and the top of the pressing column 11 is spherical, and the upper surface of the substrate 1 is also provided with a support that is lower than the pressing column 11 and has a spherical top. Column 12; in the natural state, the upper surface of the liner 21 is higher than the highest point of the pressing column 11; the natural state her...

Embodiment 3

[0080] Embodiment 3: the difference with embodiment 2 is that the thickness of the latex cotton layer is 13cm; the hole density of the elastic polyester cotton layer 23 is 92%; the height of the upper surface of the lining layer 21 and the highest point of the pressing column 11 The difference is 1.8cm; the height of support column 12 is 2.5cm; the distance between adjacent support block one 131 and support block two 132 is 1.2cm; the width of support block one 131 is 1.3cm; the width of support block two 132 is 2.8cm ; The distance between adjacent support block 1 161 and support block 2 162 is 1.2cm; the width of support block 1 161 is 1.3cm, and the width of support block 2 162 is 2.8cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com