Energy generating installation, especially wind power installation

A kind of wind power generation equipment, energy generation technology, applied in the direction of wind power generator components, wind power generation, wind power engine, etc., can solve the problems of long time length, inappropriateness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

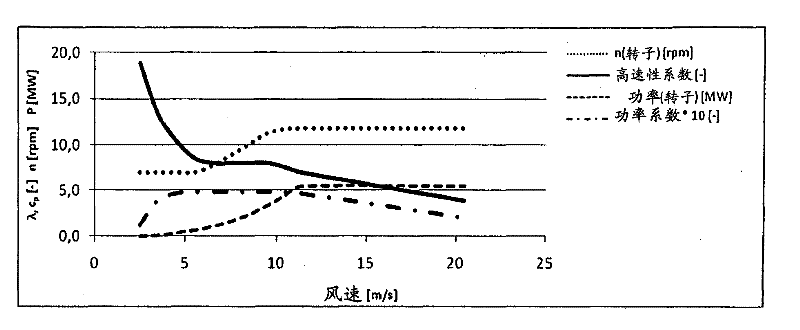

[0028] The power of the rotor of the wind power plant is calculated according to the following formula:

[0029] Rotor power = rotor area × power coefficient × wind speed 3 ×air density / 2

[0030] Among them, the power coefficient depends on the high-speed coefficient of the wind power generation equipment (=the ratio of the tip speed of the blade to the wind speed). The rotor of a wind power plant is designed for an optimum power coefficient on the basis of a high-speed coefficient determined during the development process (mostly values between 7 and 9). For this reason, correspondingly low rotational speeds can be set when the wind power plant is operated in the partial load range in order to ensure optimum aerodynamic efficiency.

[0031] figure 1 The relationship of rotor power, rotor speed, high speed coefficient and power coefficient is shown for the predetermined speed range of rotor or optimum high speed coefficient of 8.0 to 8.5. It can be seen from the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com