High performance cement and production process

A high-performance, cement technology, applied in the field of pure Portland cement, can solve the problems of insufficient strength, low construction performance of high-strength, difficulty in producing high-strength concrete, etc., and achieve the effect of easy processing and high frost resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

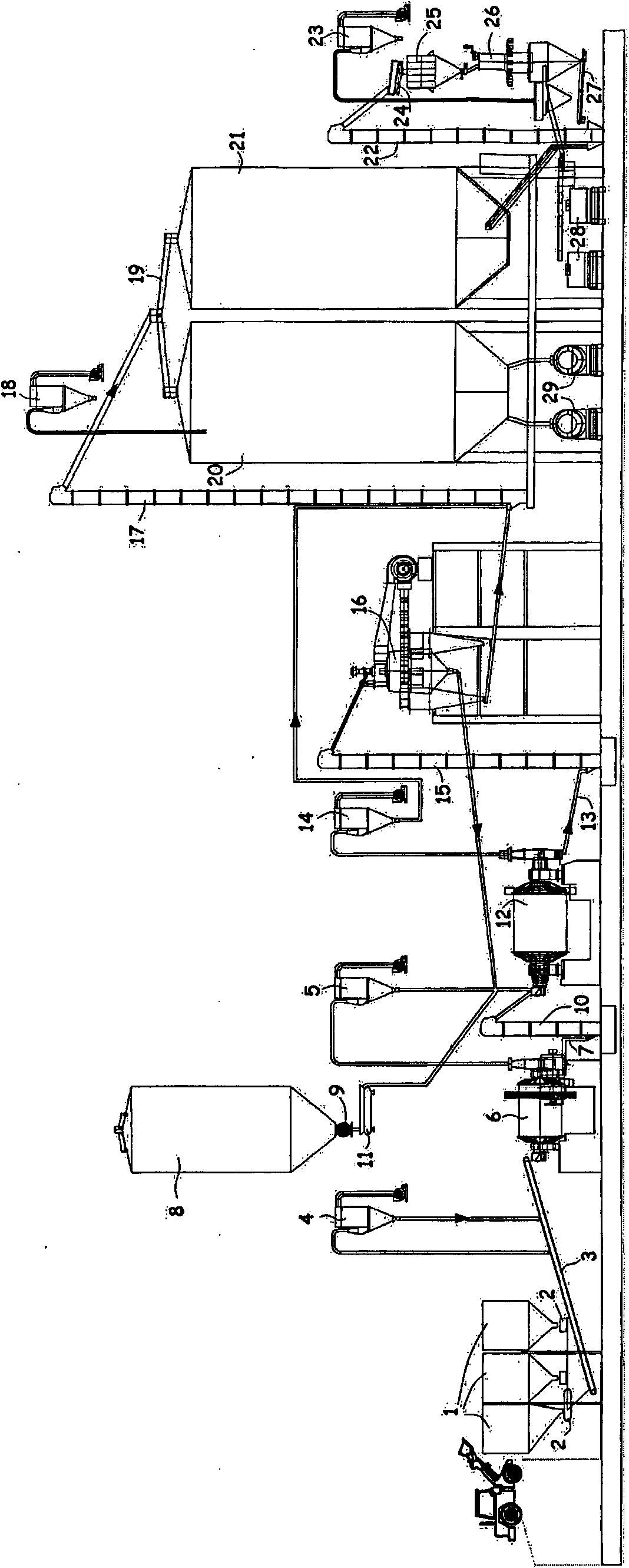

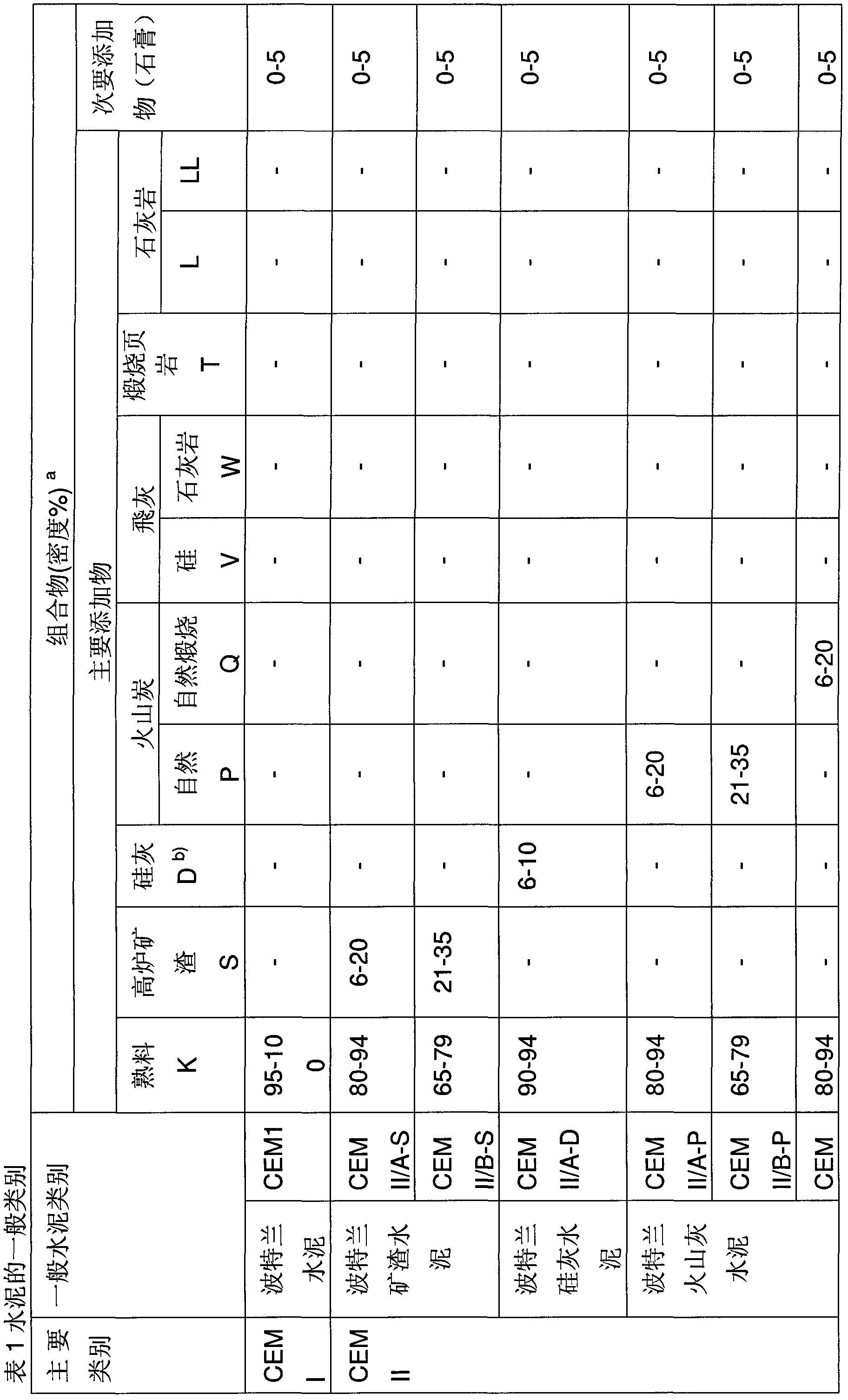

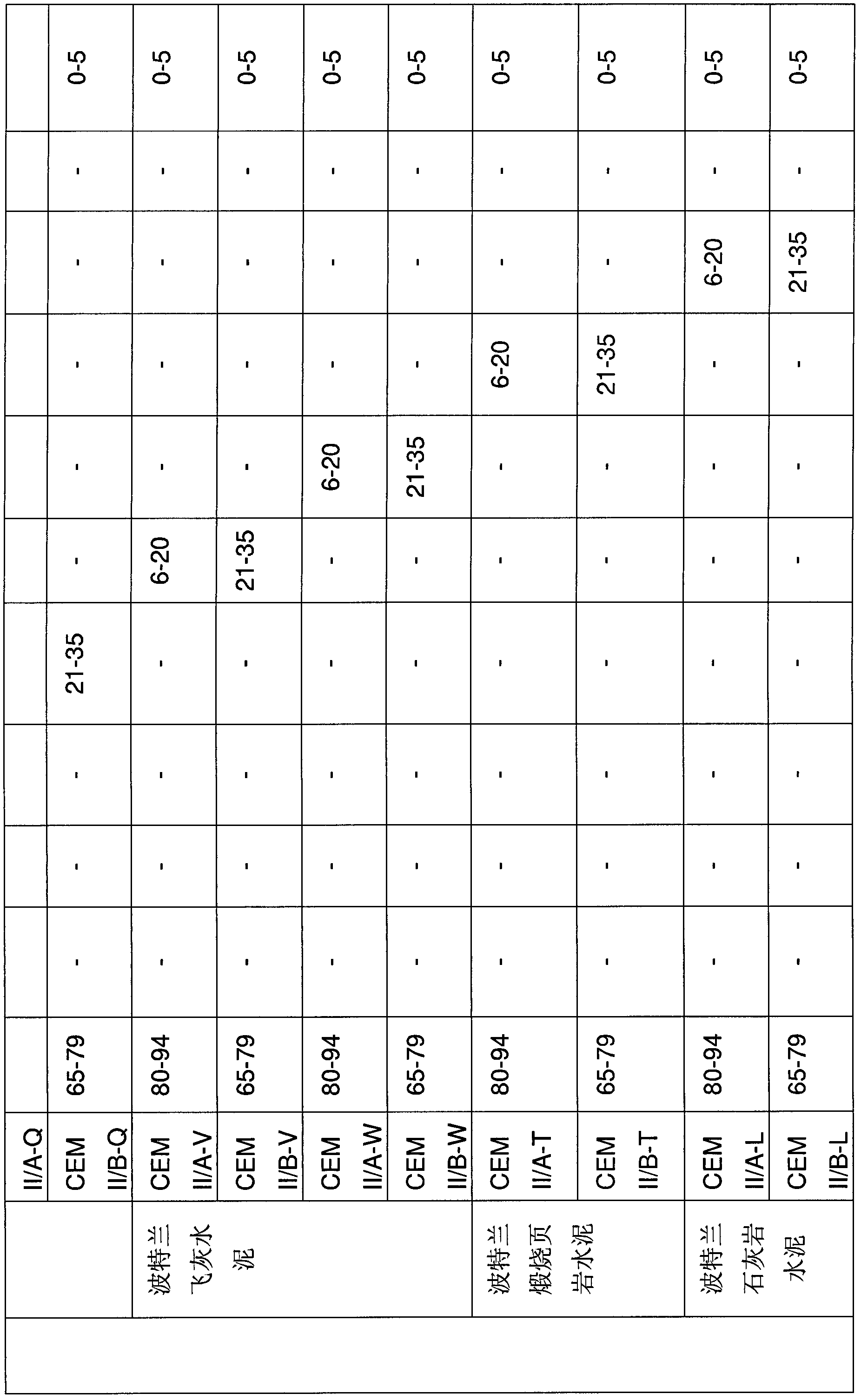

[0049] The present invention relates to the production of High Performance Cement (HPC) by adding modifiers and using special grinding techniques (regarding compliance with specific conditions during grinding, such as temperature profile, humidity, grinding time) to improve the general cement used as a structural building material. Dispersion and responsiveness of Portland clinker. The invention also relates to the production method and production components of high performance cement (HPC).

[0050] During the production of the subject high performance cement (HPC), the main raw materials are Portland clinker, gypsum and modifiers with certain proportions of clinker content. Although, any clinker can be used in the production of high performance cement, the percentage of modifier varies according to the chemical nature and quality of the clinker used.

[0051] The present invention provides a method for improving the chemical and mechanical properties of cement particles, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com