Intelligent control system for tractor component assembling line

An intelligent control system and component assembly technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of low reliability of component assembly, affecting the stability and safety of the assembly line of tractor components, and inability Keep abreast of the working status of operating equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

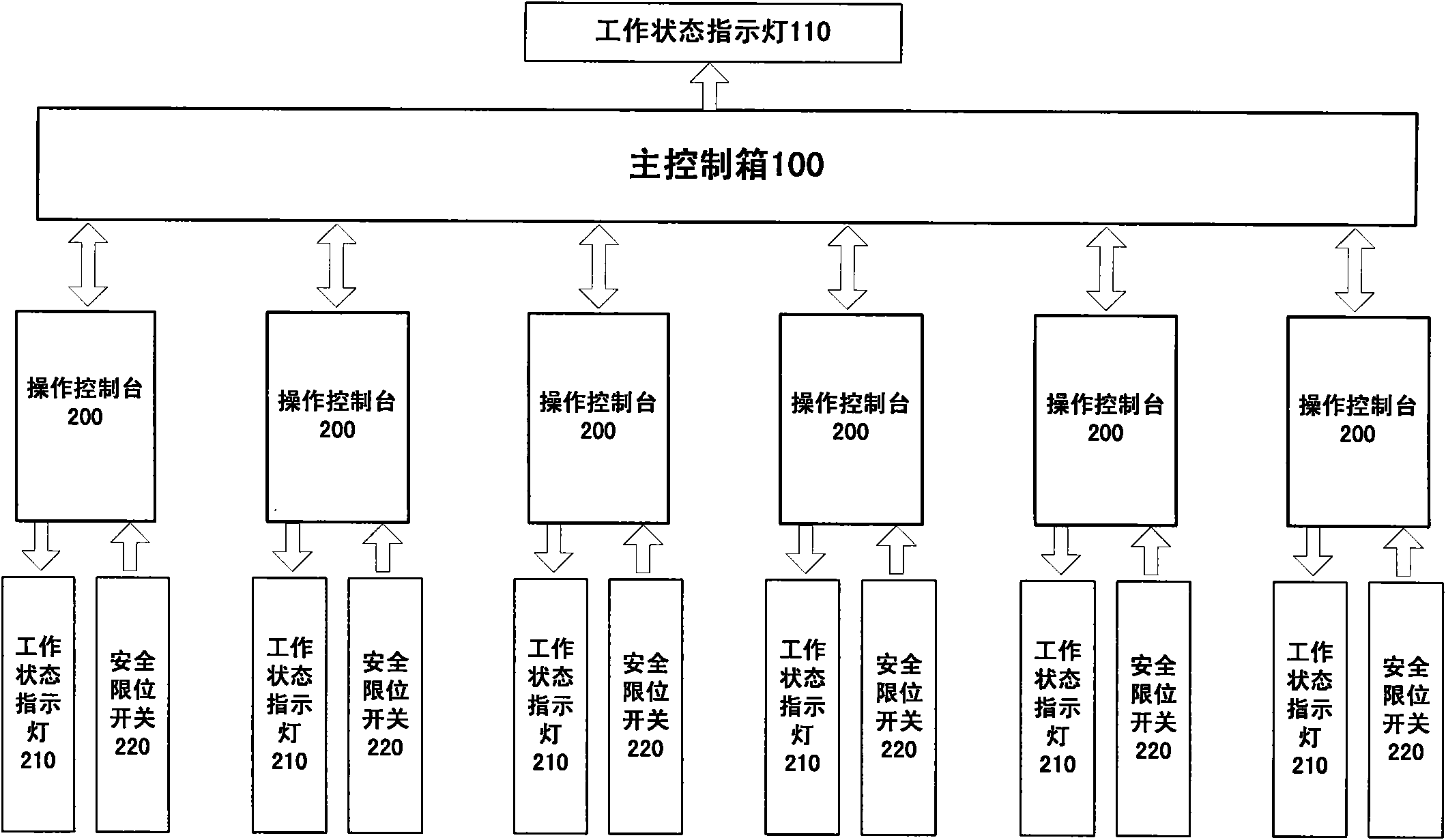

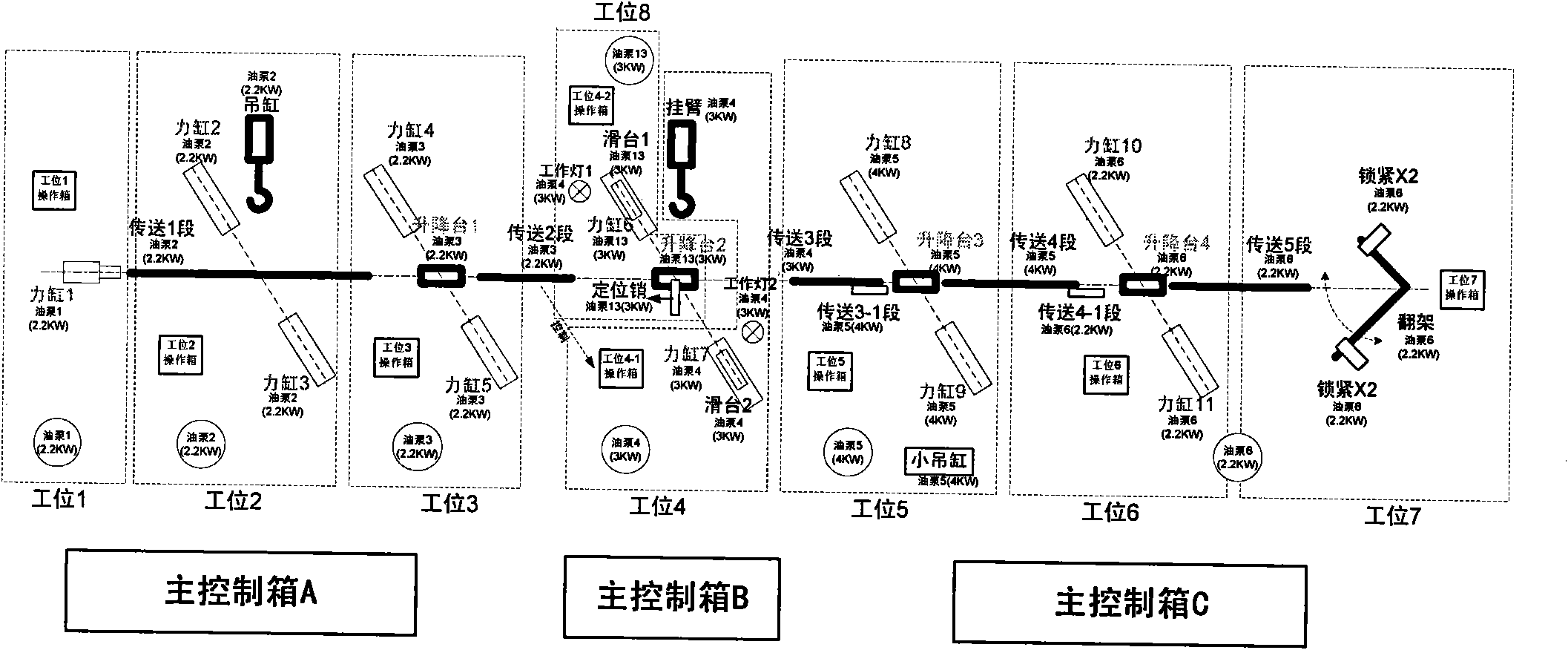

[0033] In this embodiment, the tractor component assembly line is provided with 8 stations, and each station is provided with an operation console 200, that is, there are 8 operation consoles, the oil pump motor of each station, all power cylinders, The actions of operating equipment such as conveyor belts, hanging walls, hanging cylinders, and lifting platforms are all driven by hydraulic pressure.

[0034] In this embodiment, the main control box 100 includes a main control box A, a main control box B, and a main control box C; the main control box A controls the operation of No. Control the operation of No. 4 and No. 8 stations and No. 4 and No. 8 oil pump motors, and the main control box C controls the operation of No. 5-7 stations and No. 5 and No. 6 oil pump motors. (see image 3 )

[0035] The main control box A controls the operation of No. 1-3 oil pump motors and all actions of No. 1-3 stations.

[0036] Actions at station 1 include:

[0037] The oil pump 1 is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com