Flexibility rectification adjusting device of punching machine

A compensation adjustment, mechanical technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as large contact area, inability to obtain, and difficulty in ensuring endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

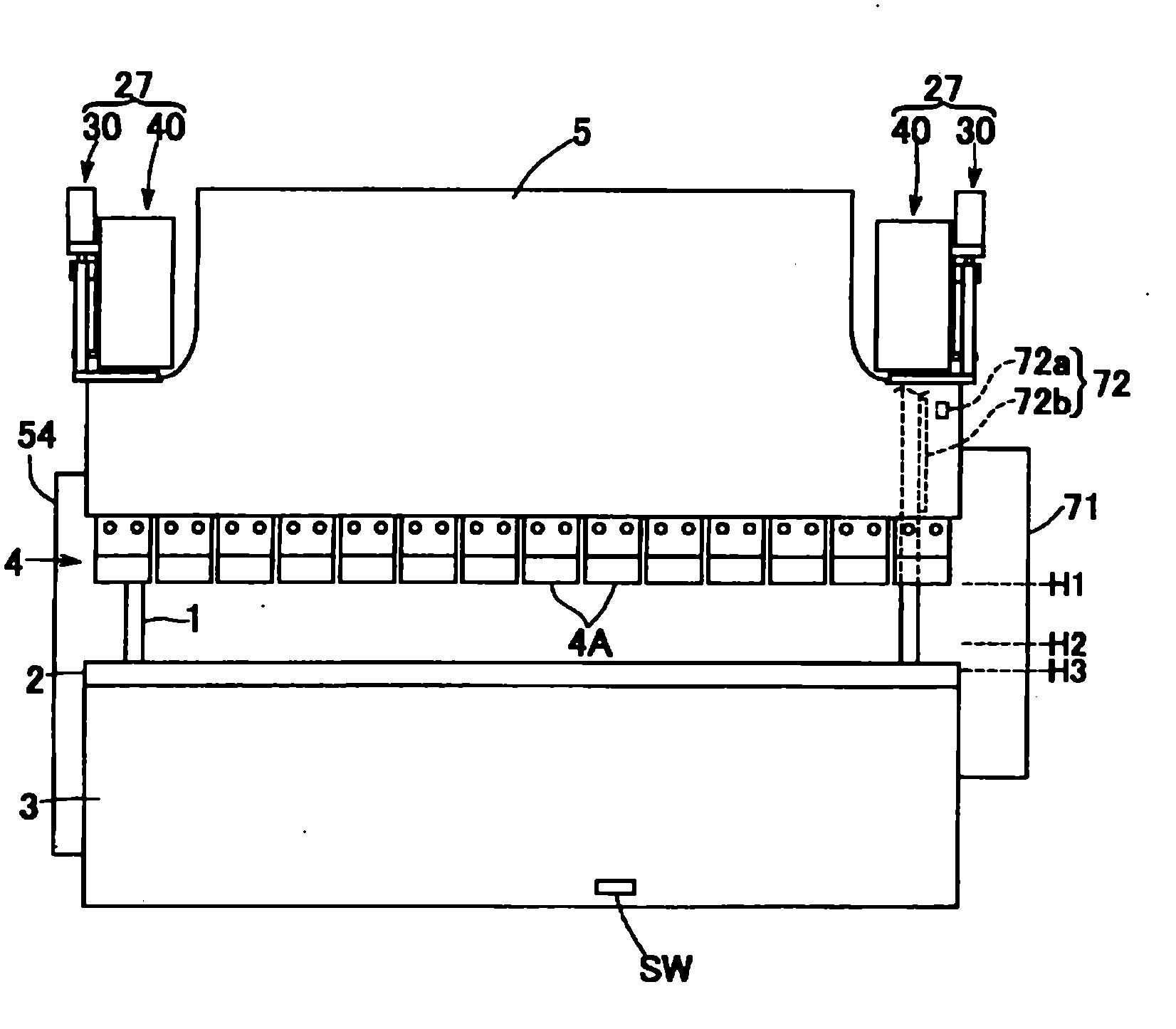

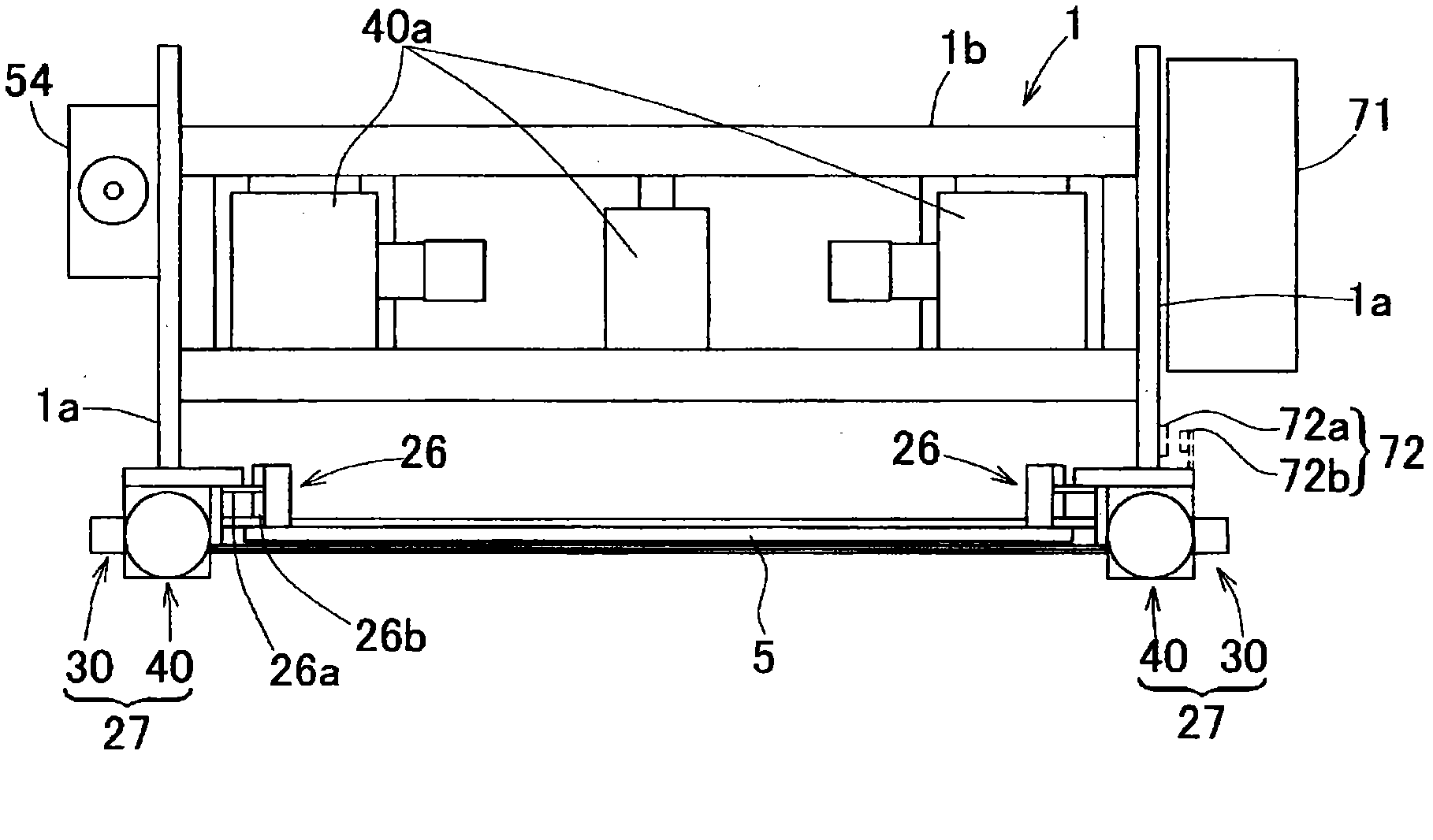

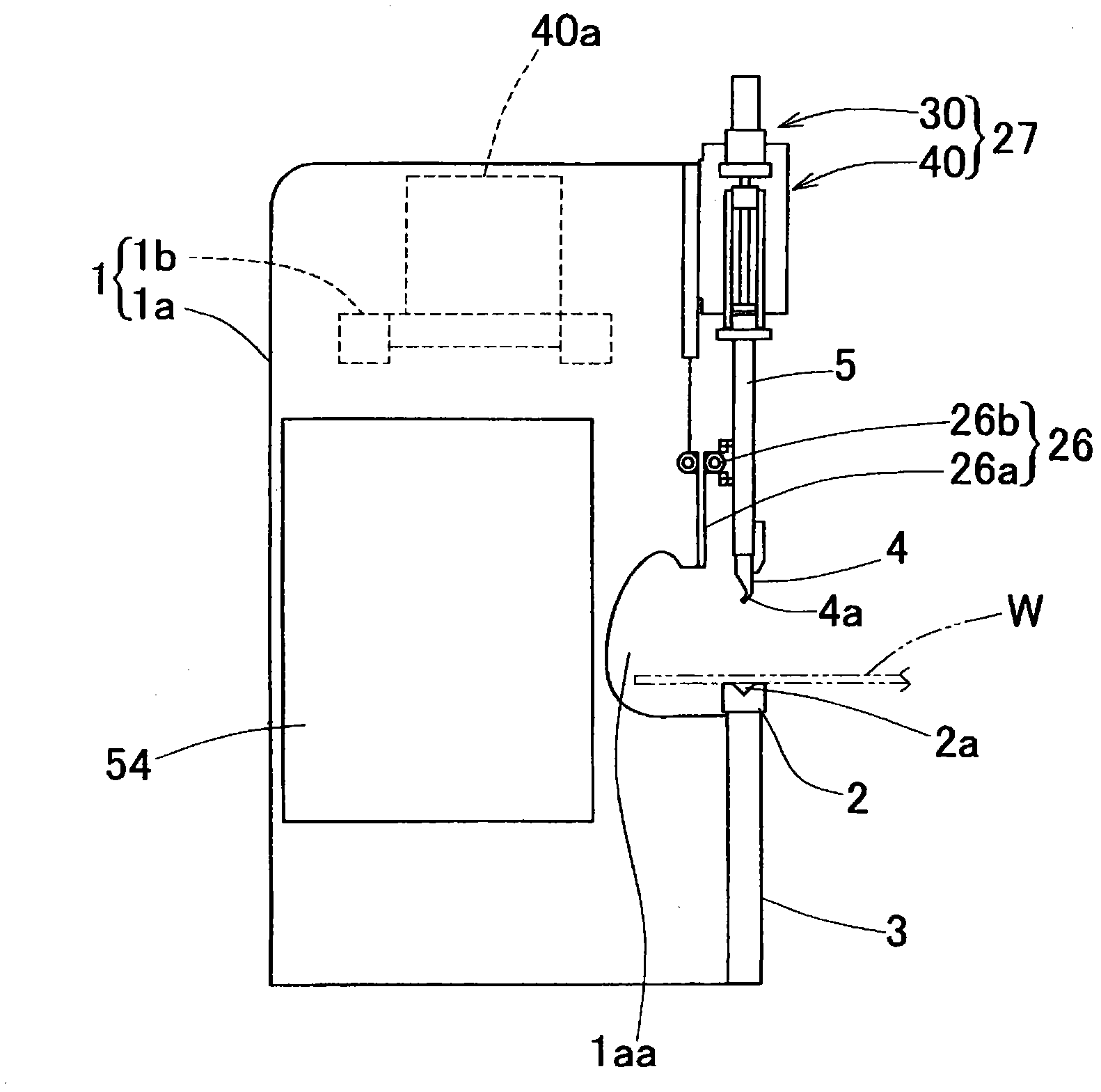

[0042] An embodiment of the present invention will be described with reference to the accompanying drawings. figure 1 is a front view of the press machine according to this embodiment, figure 2 is a top view of the stamping machine, image 3 It is a side view of the press machine. This press machine is a plate bender. On the front side of the main body frame 1, there are provided a table 3 as a fixed support member that supports a lower die 2 that is a die on a fixed side, and an upper die 4 that supports a die on a movable side. The pressure head (ram) 5 as a movable supporting part. The workbench 3 is fixed in position with respect to the main body frame 1, and the indenter 5 passes through the guide mechanism 26 ( figure 2 , image 3 ) can be lifted. Lower mold 2 is to have the concave portion 2a ( image 3 ) is an integrated mold that is longer in the left and right directions. The upper die 4 has an end portion 4a ( image 3 ), which is the mold with the same l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com