Heating-type dynamically adjustable steam-water directly mixing heat exchange device

A heat exchange device and dynamic adjustment technology, applied in the field of heat exchange, can solve the problems of reducing heat exchange efficiency and operation safety, and unable to continuously adjust the state of the mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

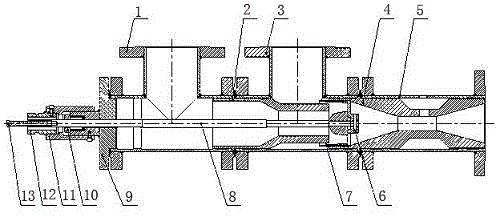

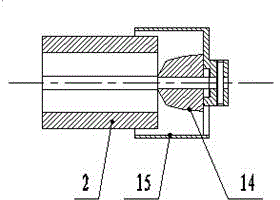

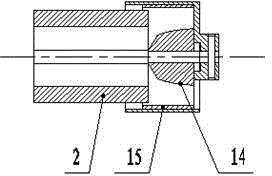

[0015] Such as figure 1 combine image 3 As shown: the heating-type dynamic adjustment steam-water direct mixing heat exchanger described in this embodiment includes a front three-way 1, a front core 2, a middle three-way 3, a center core 4, a long two-way 5, an elastic cylindrical pin 6, Adjusting device 7, main shaft 8, sealing flange 9, sealing member 10, support sleeve 11, motor base 12, motor connecting shaft 13, sealing flange 9, front three-way 1, middle three-way 3, and long two-way 5 pass in sequence The flange on the end face is fixedly connected as one, the front core 2 is coaxially arranged in the middle tee 3, the center core 4 is nested between the middle tee 3 and the long two-way 5, and between the front core 2 and the center core 4 An adjustment device 7 is provided, and the adjustment device 7 can move axially forward and backward horizontally under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com