Rotary drilling rig and control mode thereof

A technology of a rotary drilling rig and a control method, which is applied in directions such as rotary drilling rigs, drilling equipment and methods, and automatic control systems for drilling, can solve problems such as equipment wear and low efficiency of drilling rod locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

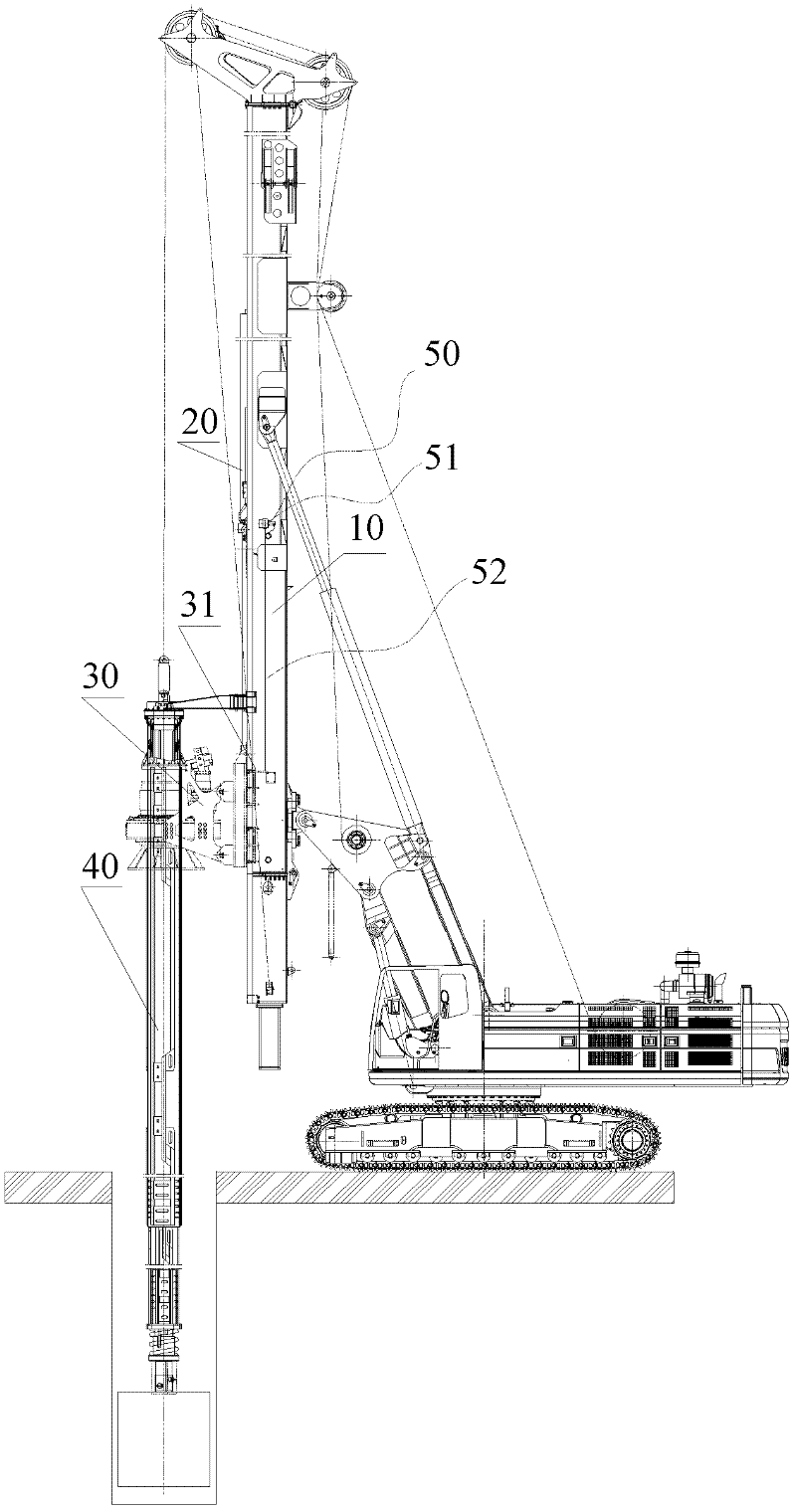

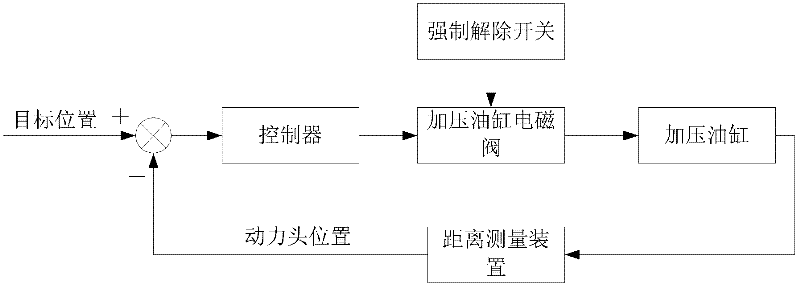

[0022] figure 1 A schematic view showing the working state of an embodiment of the rotary drilling rig according to the present invention; figure 2 It shows the schematic diagram of the unloading state of the embodiment of the rotary drilling rig according to the present invention. see in conjunction Figure 1 to Figure 2 , As can be seen from the figure, the rotary drilling rig of this embodiment includes: a mast 10, a pressurized cylinder 20, a power head 30, a drill pipe assembly 40, a main winch, a distance measuring device 50 and a controller.

[0023] The mast 10 is the supporting part of the drill pipe assembly 40. It is subjected to torque, vibration, etc. during work, and the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com