Aluminum alloy building template assembly

A technology of building formwork and aluminum alloy, which is applied in construction, on-site preparation of building components, building structure, etc., can solve the problems of messy construction site, no residual value, large loss of square wood, etc., and achieve less joints and reduce Labor and material costs, high precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

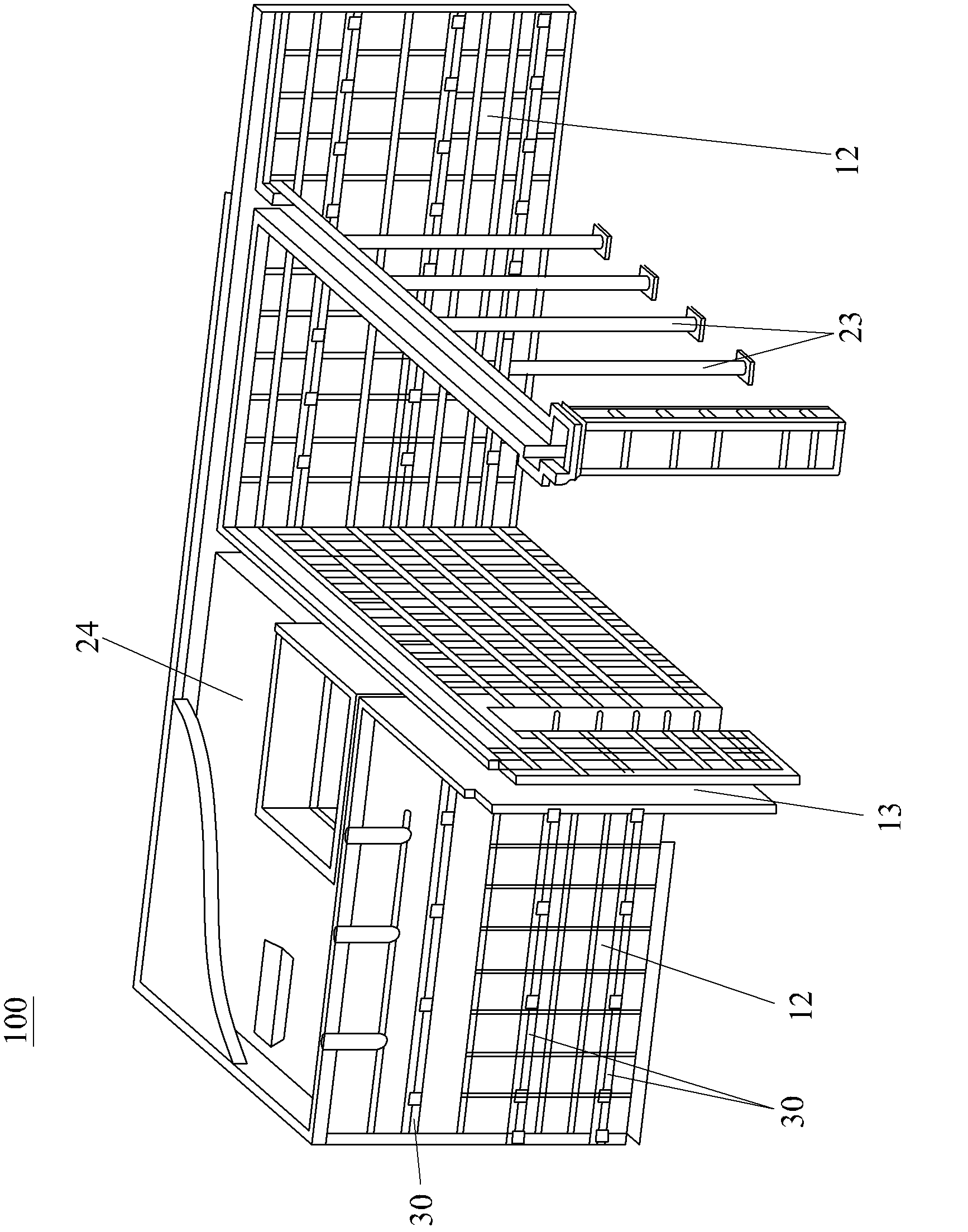

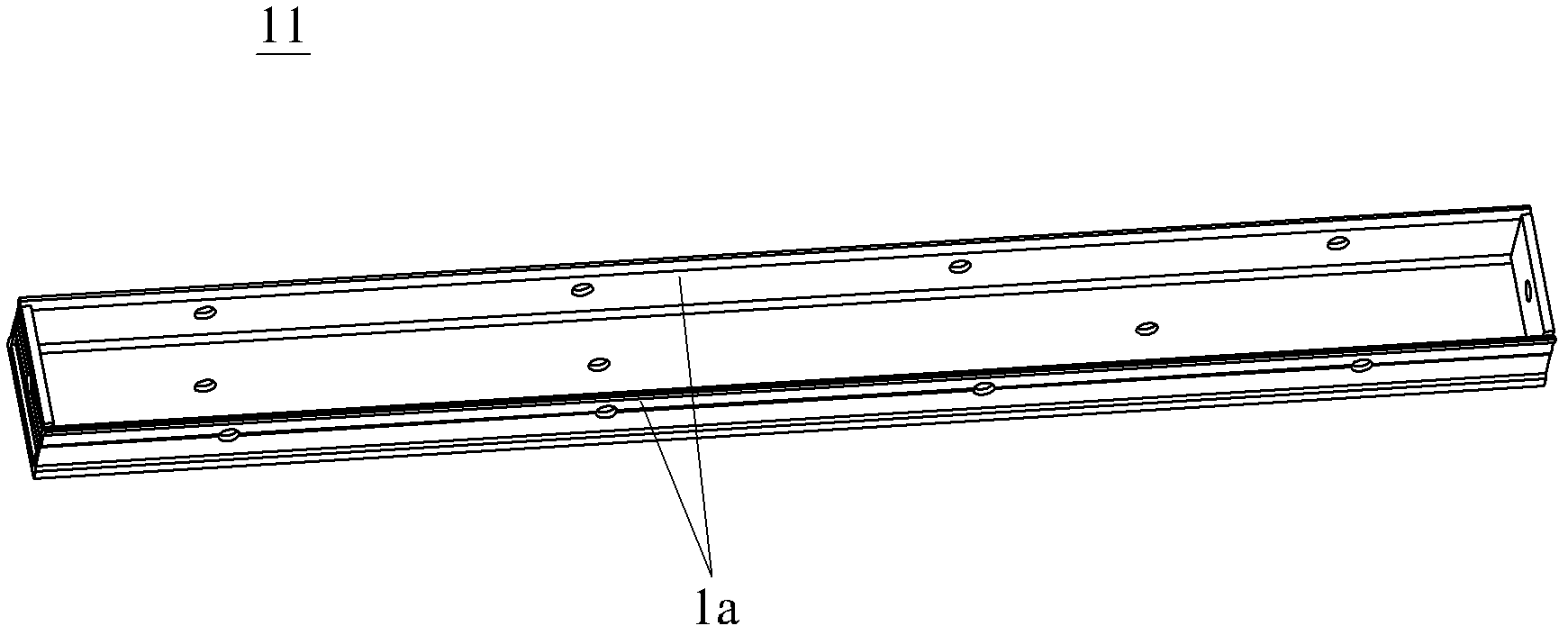

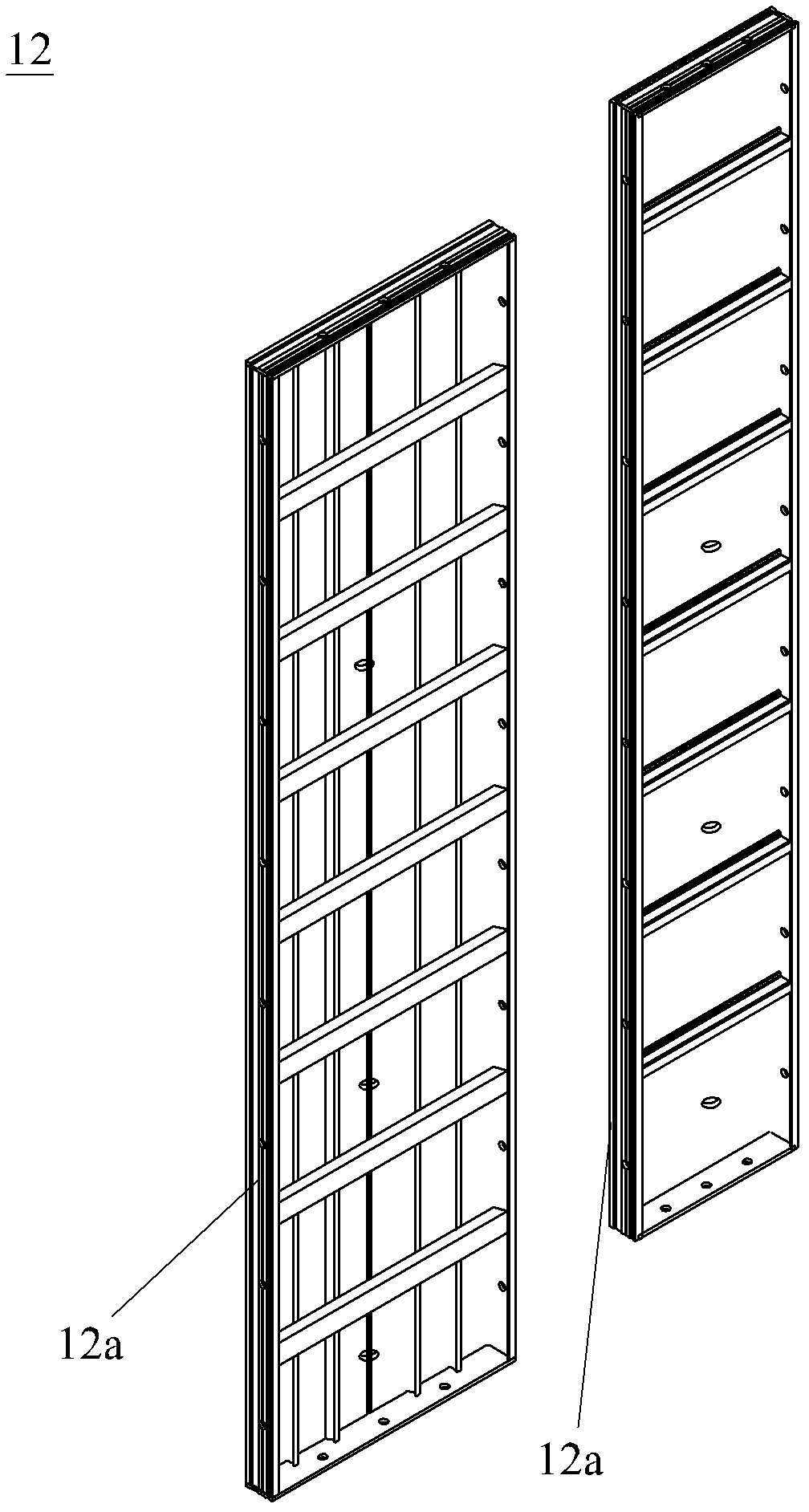

[0017] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as Figure 1-6 As shown, the aluminum alloy building formwork assembly 100 provided by the present invention includes: a wall panel assembly and a floor panel assembly. The wall assembly panel includes a starting board 11 and a wall board 12. The starting board 11 is placed horizontally and The sides are bent upwards and extended to form a mounting plate 1a, on which the wall panels 12 are installed, and the inner surfaces of the wall panels 12 are opposite to form a concrete pouring groove 13, and the floor panel assembly includes a roof Board 21, keel beam 22 and support shaft 23, the roof slab 21 is connected with the wall panel 12, the support shaft 23 is supported on the lower surface of the roof slab 21 by the keel beam 22, the The upper surface of the roof slab 21 forms a concrete pouring su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com