High-efficiency and environmentally-friendly shilling rudder body

A fishtail rudder, an environmentally friendly technology, applied in the direction of rudder steering, etc., can solve the problems of rudder promotion, slow development, poor ship maneuverability, and small lift-drag ratio coefficient, so as to improve slewing performance and lateral movement ability, increase steering The effect of ship moment and high lift-to-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

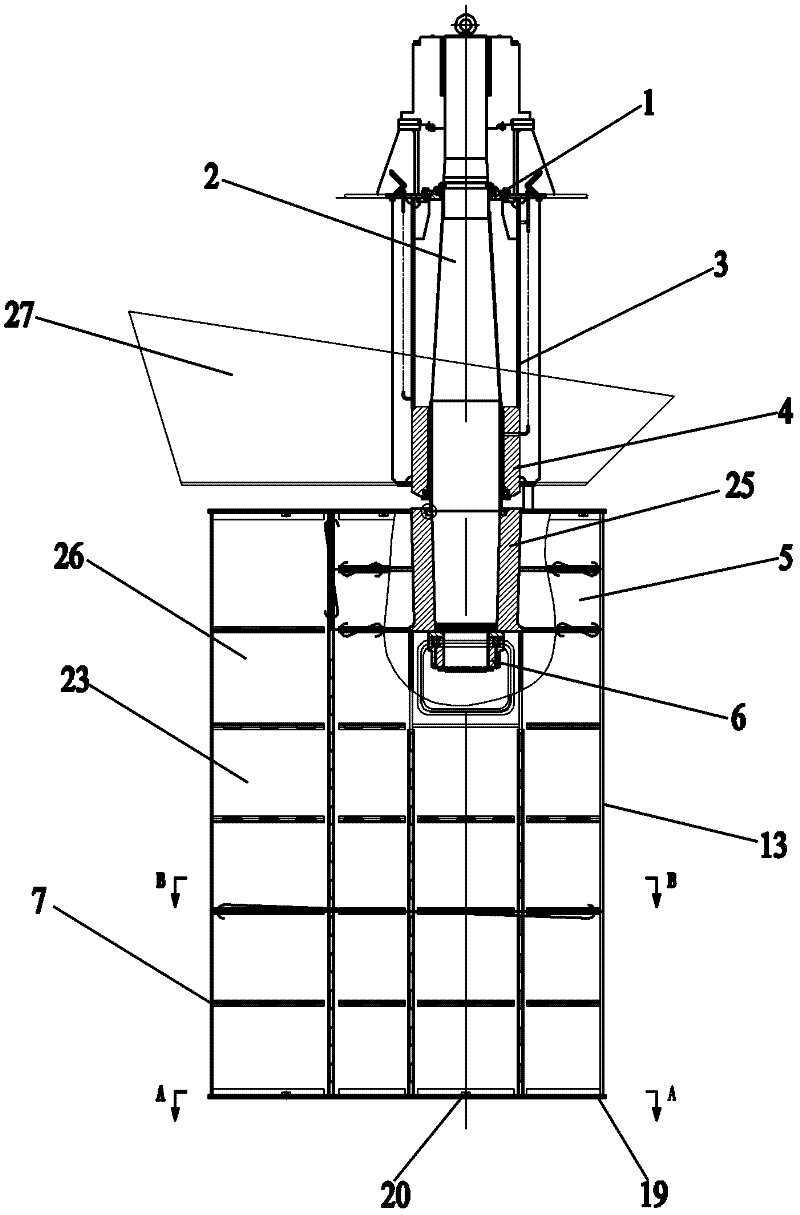

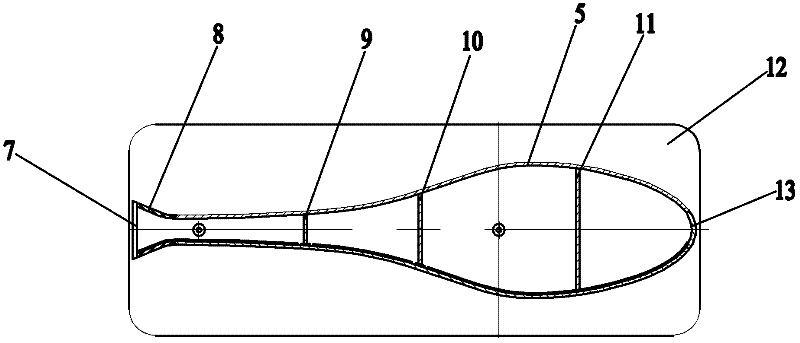

[0016] Such as Figure 1~Figure 3 As shown: the present invention includes a sealing device 1, a rudder stock 2, a connecting sleeve 3, a lower rudder bearing sleeve 4, a rudder blade side plate 5, a hydraulic nut 6, a tail seal plate 7, a side plate 8, and a first vertical rib Plate 9, second vertical rib 10, third vertical rib 11, upper damper 12, bow seal 13, first horizontal rib 14, backing plate 15, second horizontal rib 16, third Horizontal ribs 17, fourth horizontal ribs 18, lower damping plate 19, drain cock 20, first water hole 21, second water hole 22, third water hole 23, fourth water hole 24, rudder blade connection Body 25, rudder blade body 26 and false rudder 27.

[0017] Such as figure 1 , figure 2 and image 3 As shown: one end of the rudder stock 2 is provided with a sealing device 1, and the other end of the rudder stock 2 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com