Controlling device capable of automatically cutting off train pipe and exhausting in case of undervoltage main blast line and control method

An automatic cut-off and control device technology, which is applied in the direction of pneumatic brakes, railway car body parts, hydraulic brakes, etc., can solve problems such as failure to implement braking protection measures in time, locomotive safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

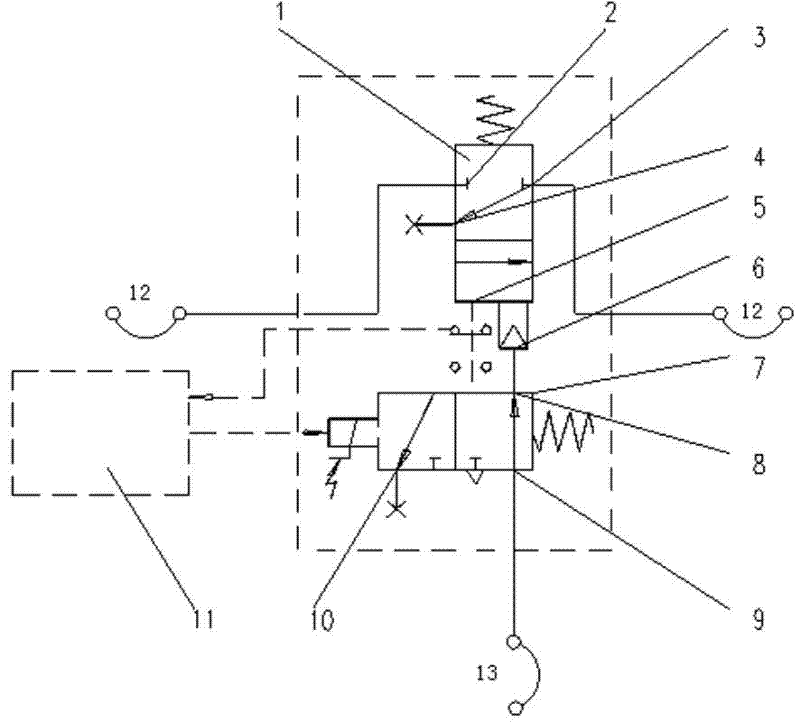

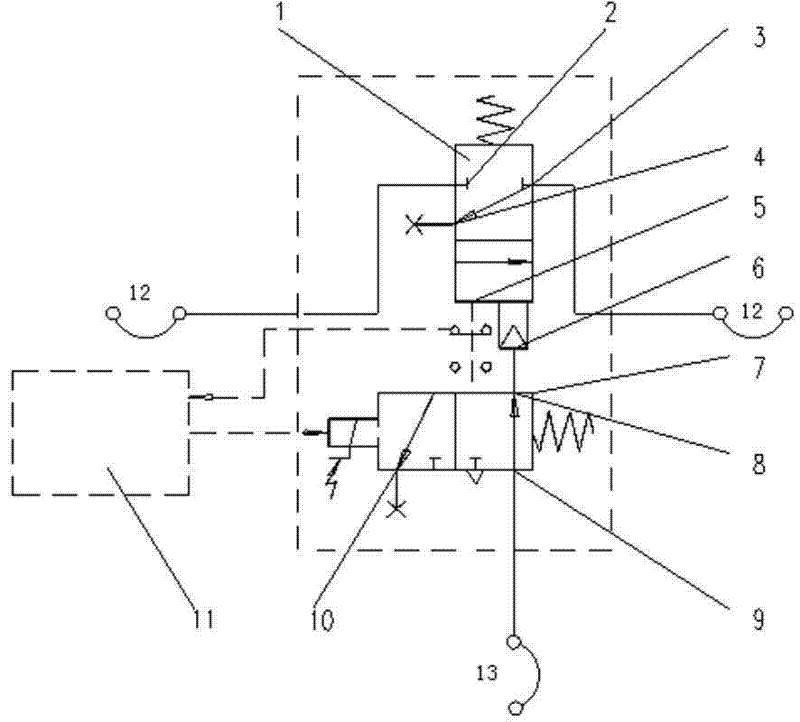

[0014] Such as figure 1 As shown, a control device for automatically cutting off and exhausting the train pipe under pressure in the main air pipeline, including a pneumatic valve 1, the bottom of the pneumatic valve 1 is provided with a micro switch 5 for monitoring the state of the pneumatic valve, and the two sides of the pneumatic valve 1 are provided with Valve ports 2 and 3, valve port 2 is connected to the outlet of the train pipe 12 of the locomotive balance air cylinder relay valve, and valve port 3 is connected to the inlet of the train pipe 12 of the locomotive distribution valve; one side of the pneumatic valve 1 is also provided with an air exhaust port 4, It communicates with the atmosphere.

[0015] The bottom of the pneumatic valve 1 is provided with an enabling valve port 6, and the pneumatic valve 1 is provided with a solenoid valve 7 for controlling the total air pressure of the locomotive. The air outlet 8 at the top of the solenoid valve 7 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com