Powerless low-temperature isobaric ammonia recovering method and isobaric ammonia recovering device

An ammonia recovery and ammonia recovery tower technology, applied in separation methods, chemical instruments and methods, ammonia preparation/separation, etc., can solve the problems of large total water volume, large consumption of steam and electricity, low utilization rate of cooling area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

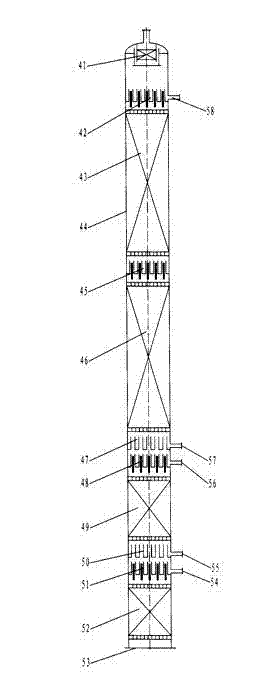

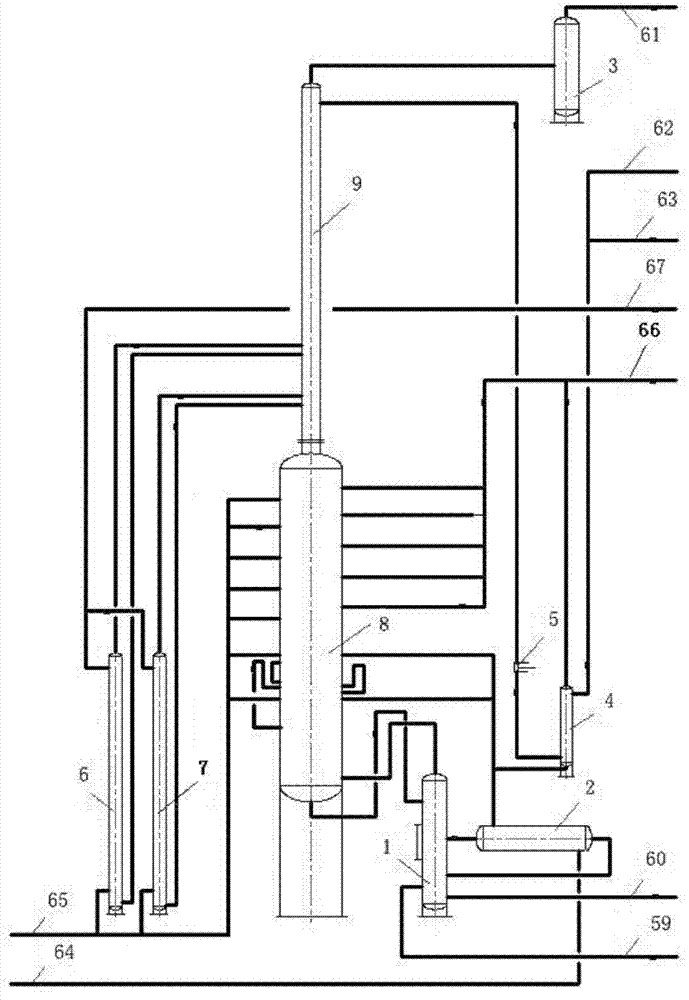

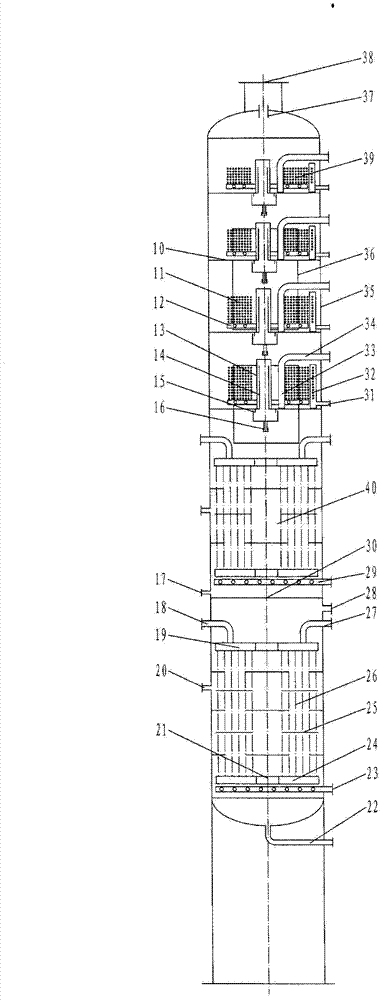

[0122] Unpowered low temperature isobaric ammonia recovery method:

[0123] see figure 1 , the isobaric ammonia recovery tower is composed of two parts, the bubbling absorber 8 at the bottom and the newly added packing scrubber 9 at the top, which are connected by flanges for the convenience of transportation; before the relaxation gas inlet 23 of the bubbling absorber 8 A circulating absorption separator 1 is added, and the outlet and inlet of the high-concentration ammonia water of the circulating absorption separator 1 are connected with the inlet and outlet of the newly added high-concentration ammonia water cooler 2 outside the tower to form a circulation loop for absorbing and cooling the high-concentration ammonia water; The gas outlet of the packing scrubber 9 is connected to the water separator 3, the water inlet is connected to the desalted water pump 5, and a desalted water cooler 4 is added at the inlet or outlet of the desalted water pump 5; A small ammonia water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com