Vacuum low temperature cooking machine

A vacuum low temperature, cooking machine technology, applied to cooking utensils, cooking utensils with water bath devices, household appliances, etc., can solve problems such as uneven water temperature, deviation between displayed temperature and real temperature, affecting food quality, etc., to save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

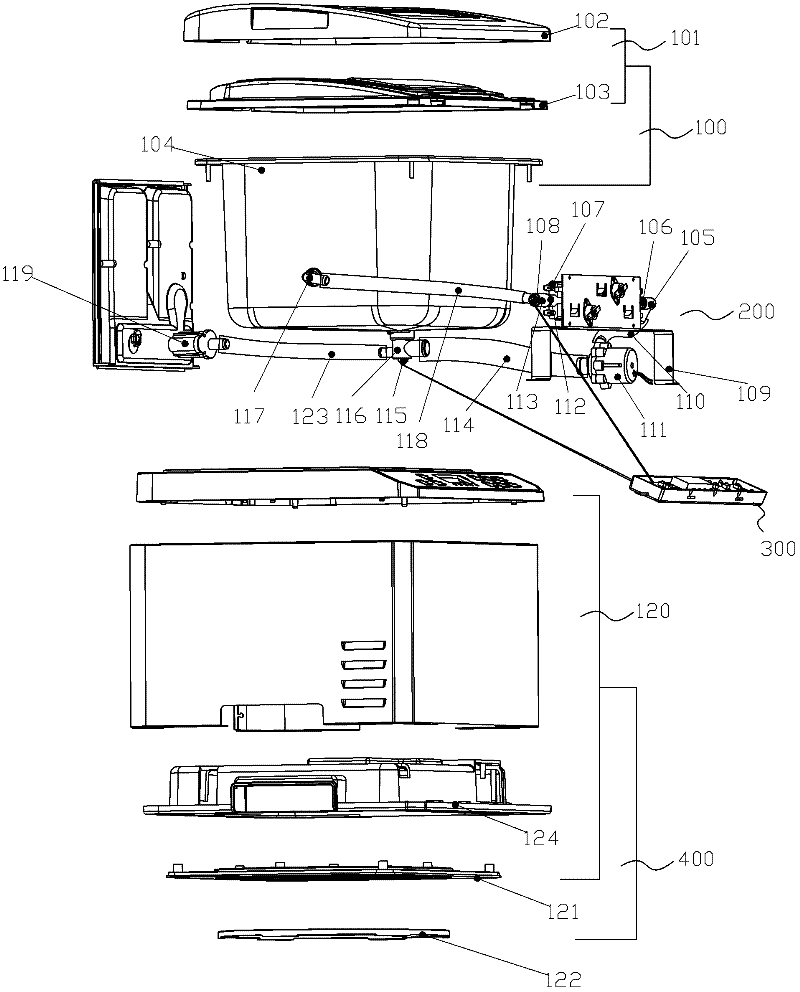

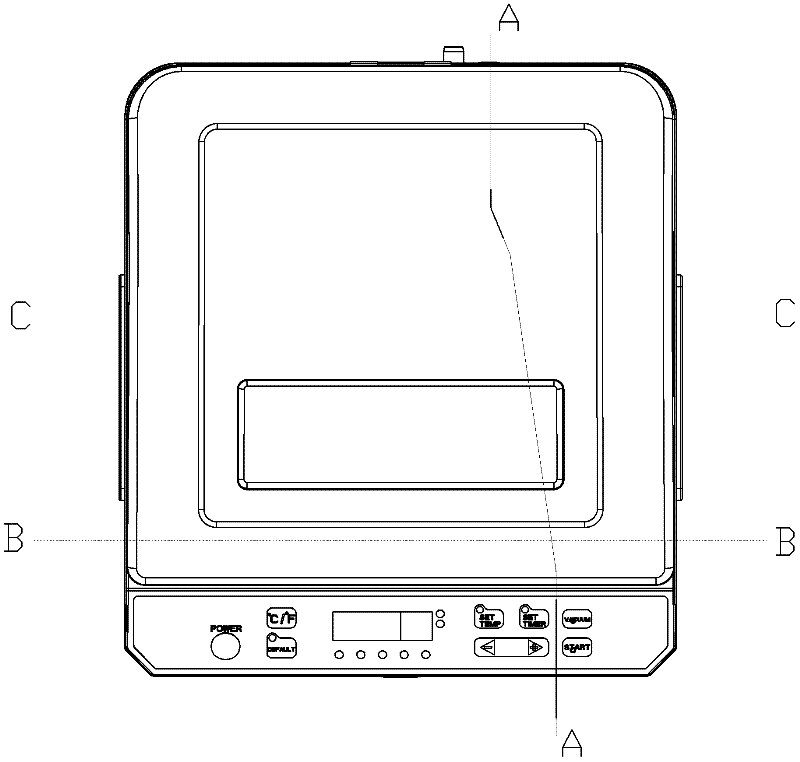

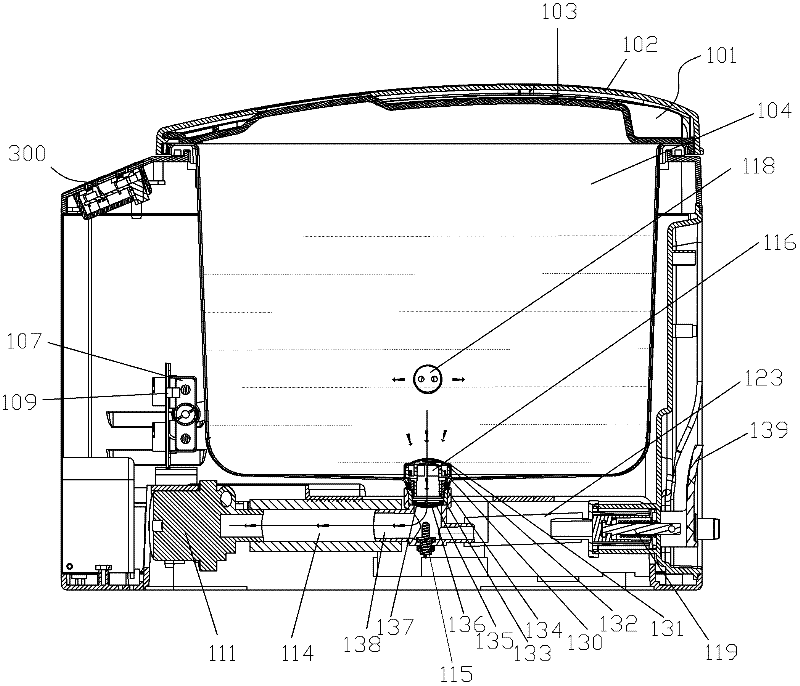

[0035] Such as figure 1 , 2 As shown, the vacuum low temperature cooking machine of the present invention includes a container 100, a heating circulation system 200, and a casing 400 for installing the container 100 and the heating circulation system 200. The container 100 is composed of: a water basin 104 for cooking water , a machine cover 101 covering the water basin 104 is formed, and the heating circulation system 200 is composed of: a water pump 111, a heater 107, and a group of electronic control systems 300, and the electronic control system controls the operation of the heater 107 to accurately maintain the temperature of the water in the container 100 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com