Method for preparing ayfivin compound protein feed additive by degrading feather with bacillus licheniformis

A technology of Bacillus licheniformis and feed additives, applied in the field of resource utilization of waste, to achieve the effects of saving resources, high compound content of bacterial peptides, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the pretreatment of feather

[0049] After the original feathers are purchased from the vegetable market, they must first be spread out to remove impurities such as duck skin and viscera; then rinse and soak in tap water for 20 minutes, press the water dry, soak for another 10 minutes, press the water dry, and air-dry them Prepare 0.02% NaOH solution, heat it to boiling, put the feathers into it (about 200g of dry feathers can be processed per liter of the NaOH solution), take out the feathers after 15 minutes, filter the NaOH solution and squeeze the feathers until no solution seeps out, Soak in tap water for 2 minutes, squeeze the feather again until no solution seeps out. until the feather pH is neutral. Dry the feathers at 60°C until the quality does not increase any more.

Embodiment 2

[0050] Embodiment 2: the preparation of seed solution

[0051] Streak the CCTCCM208251 strain preserved in the eggplant-shaped bottle on a solid LB plate to activate it. Select a single colony from the above LB plate and inoculate in 12 bottles of 250 mL Erlenmeyer flasks containing 100 mL of liquid LB medium, put them in a shaker, and cultivate them at 37 ° C and 220 rpm for 10 h. Samples were taken from each bottle of fermentation broth and sent for microscopic examination. All 12 bottles of fermentation broth were free of pollution and grew vigorously. Inoculate above-mentioned primary seed fermented liquid in the 40L fermentation tank by the ratio of 10%, contain 25L liquid LB culture medium in the tank, carry out secondary seed expansion cultivation. After 7 hours of fermentation, samples were taken for microscopic examination, and the results of microscopic examination showed no pollution. Keep the uncontaminated fermentation broth in the fermenter for later use. Micr...

Embodiment 3

[0052] Embodiment 3: the shake flask fermentation of inoculating 100mL feather fermentation substrate by fermentation substrate volume 5%:

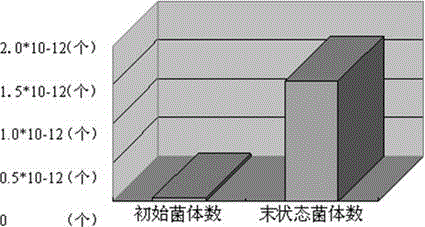

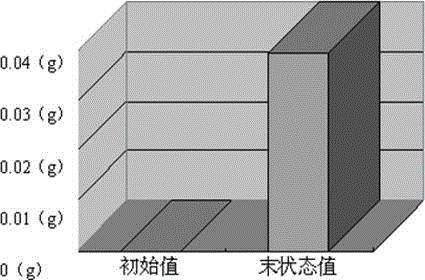

[0053] Feather bio-fermentative degradation was carried out in 250mL Erlenmeyer flasks, and the filling volume of each Erlenmeyer flask was 100mL. Inoculate Bacillus licheniformis at 5% in the fermentation substrate sterilized at 121°C for 30 minutes. The composition of the fermentation substrate is: (w / v%) 0.3% potassium nitrate, 0.1% dipotassium hydrogen phosphate, 0.06% dihydrogen phosphate Potassium, Magnesium Chloride Hexahydrate 0.04%, NaCl 0.5%, Sorbitol 0.1%, Feather 2%. It was fermented on a shaking table at 37° C. and 200 rpm, and the fermentation broth was observed every 12 hours until the feathers in the fermentation broth no longer decreased to stop the fermentation. The sediment contained a large amount of probiotic Bacillus licheniformis. Sampling was sent for inspection of the bacteria content and feather degradation rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com