Preparation method of jasmine tea

A production method and technology of flower crafts, applied in the field of jasmine flower tea production, can solve the problems of low utilization rate of flowers, cumbersome processing procedures, long production cycle, etc., and achieve the effect of increasing ornamental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

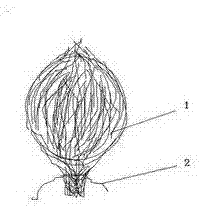

[0027] First pick the tea leaves and flowers, process the fresh tea leaves collected from the tea garden into a semi-dry state, and then wrap the petals in it with the treated tea leaves. The amount of flowers is preferably one or three, and the petals are threaded up . The lower end of the pellets is tied firmly with a thread, the upper end of the pellets is gathered, and then the whole pellets are wrapped with clean gauze (or synthetic fiber cloth). Then dry at a temperature of 60°C to 80°C, stop heating after 25-30 minutes, remove the wrapping cloth, and finally obtain a spherical tea bag with a diameter of 30 mm, which is finally put into a tea can to obtain the product.

Embodiment 2

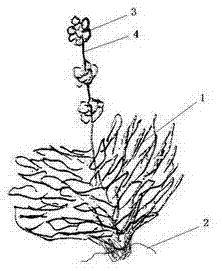

[0028] Embodiment 2: picking tea leaves and flowers, processing the fresh tea leaves collected from the tea garden into a semi-dry state, spraying the dry tea leaves into a semi-dry state, and then wrapping jasmine flowers in them with the treated tea leaves, with 1-3 flowers It is advisable to have several flowers, or make a garland or a lantern-like form, and the petals are threaded up. The lower end of the pellets is tied firmly with a thread, the upper end of the pellets is gathered, and then the whole pellets are wrapped with clean gauze. Then dry at a temperature of 60°C to 80°C, stop heating after 25-30 minutes, remove the wrapping cloth, and finally obtain a spherical tea bag with a diameter of 30mm, and scent the jasmine one or more times to let the fragrance of the flower The tea pellets are infiltrated and finally filled into tea cans to obtain the product. The product is named "Jasmine Fairy".

Embodiment 3

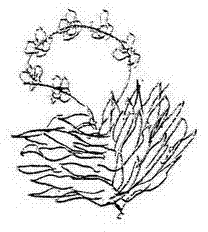

[0029] Embodiment 3: picking tea leaves and fresh flowers, spraying dry tea leaves with water to soften them, and then wrapping rose petals and jasmine flowers in them with the treated tea leaves. The amount of flowers is preferably 1-5, and the petals are threaded through them. rise. The lower end of the pellets is tied firmly with a thread, the upper end of the pellets is gathered, and then the whole pellets are wrapped with clean gauze (or synthetic fiber cloth). Then dry at a temperature of 60°C to 80°C, stop heating after 25-30 minutes, remove the wrapping cloth, and finally obtain a spherical tea bag with a diameter of 30 mm, and then put it into a tea can at last to obtain Products, the product is named "Rose Fairy".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com